Printing ink composition of solvent recovery/reuse type, diluent solvent, and method of reusing recovered solvent

A technology for printing inks and diluting solvents, applied in the field of solvents and ink compositions, can solve the problems of huge initial cost, operating cost, consumption of petroleum resources, and cost reduction must not have an impact on the environment, and achieve excellent printing suitability, easy reproducibility, etc. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

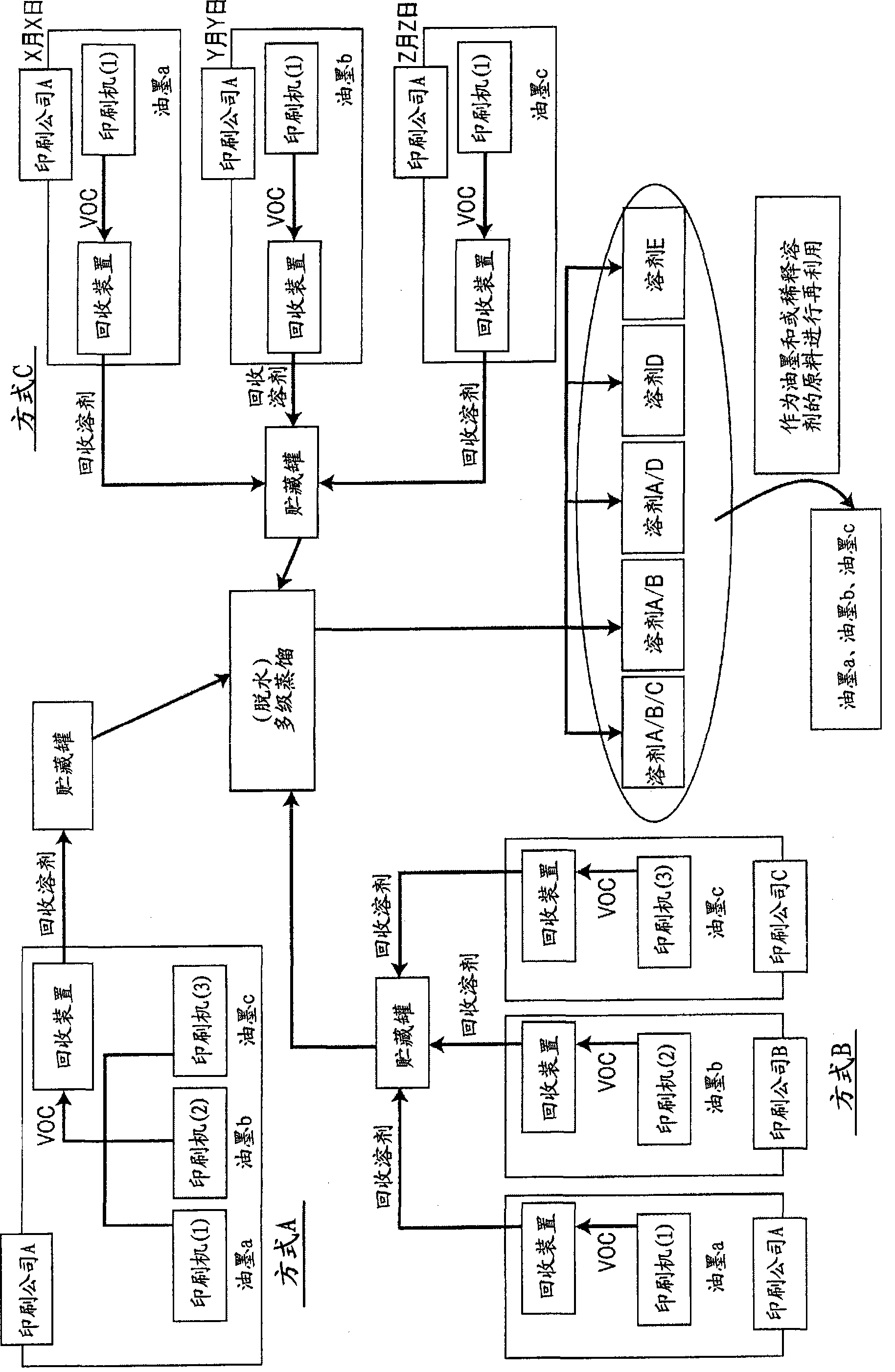

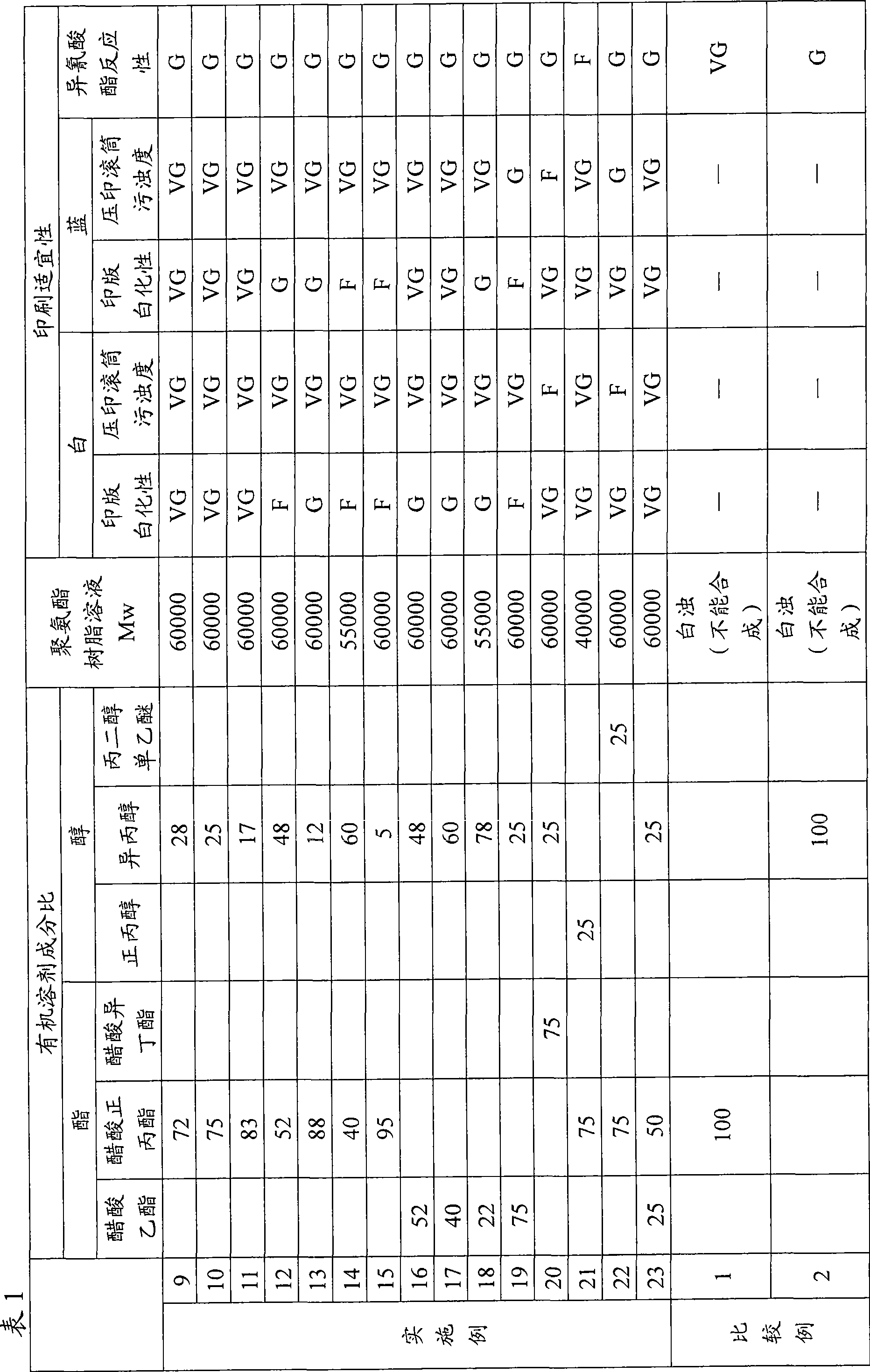

[0109] Solvent recovery and reuse type printing inks using a variety of different resins with a non-volatile solvent composition of isopropyl alcohol / methyl ethyl ketone / methylcyclohexane / n-propyl acetate / propylene glycol monomethyl ether, used in various printing machines Gravure printing is carried out, and after recovery by a recovery device using activated carbon particles as a fluidized bed, water is removed with a zeolite separation membrane, and the result is isopropanol: methyl ethyl ketone: methylcyclohexane: n-propyl acetate: propylene glycol monomethyl ether = Recovery solvent (A) of 25.0:15.0:5.0:50.0:5.0.

[0110] 100 g of this recovered solvent (A) was put into an Erlenmeyer flask, a distillation apparatus having a distillation column filled with Raschig rings was installed, and the temperature was raised while stirring with a heating stirrer.

[0111] Taking the reflux ratio as reflux (erlenmeyer flask): extraction (recovery solvent)=3:1, the result of distillat...

Embodiment 2

[0114]With respect to the recovered solvent (A) 100 in Example 1, methyl ethyl ketone (X) was added at a weight ratio of 40 to prepare a mixed solvent (B).

[0115] 100 g of this recovered solvent (B) was put into an Erlenmeyer flask, a distillation apparatus having a distillation column filled with Raschig rings was installed, and the temperature was raised while stirring with a heating stirrer.

[0116] Taking the reflux ratio as reflux (erlenmeyer flask): extraction (recovery solvent)=3:1, the result of distillation is that, by distillation, isopropanol: methyl ethyl ketone: methylcyclohexane=31.3 is obtained at a temperature of 74° C. at the top of the tower: Mixed solvent (a) 16.0g of 37.0:31.7 (weight ratio), then, obtain isopropanol: the mixed solvent (b) 58.0g of methyl ethyl ketone=34.3:65.7 (weight ratio) at tower top temperature 75.5 ℃, and then, in A single solvent of methyl ethyl ketone (f) was obtained at a tower top temperature of 78°C, and 48.2 g of a single n-...

Embodiment 3

[0119] Using solvent recovery and reuse type printing inks of various resin systems with a solvent composition of isopropyl alcohol / methyl ethyl ketone / methylcyclohexane / n-propyl acetate / propylene glycol monomethyl ether, gravure printing is performed with various printing machines, After being recovered together by a recovery device using activated carbon particles as a fluidized bed, water was removed with a zeolite separation membrane, and the result was isopropanol: methyl ethyl ketone: methylcyclohexane: n-propyl acetate: propylene glycol monomethyl ether = 25.0:15.0 :5.0:50.0:5.0 (weight ratio) of recovery solvent (A).

[0120] 100 g of this recovered solvent (A) was put into an Erlenmeyer flask, a distillation apparatus having a distillation column filled with Raschig rings was installed, and the temperature was raised while stirring with a heating stirrer.

[0121] Taking the reflux ratio as reflux (erlenmeyer flask): extraction (recovery solvent)=3:1, the result of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com