Radiating device

A heat dissipation device and heat dissipation fin technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., and can solve the problems of reduced heat dissipation efficiency of heat dissipation devices, low heat dissipation efficiency, and low utilization rate of cold air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

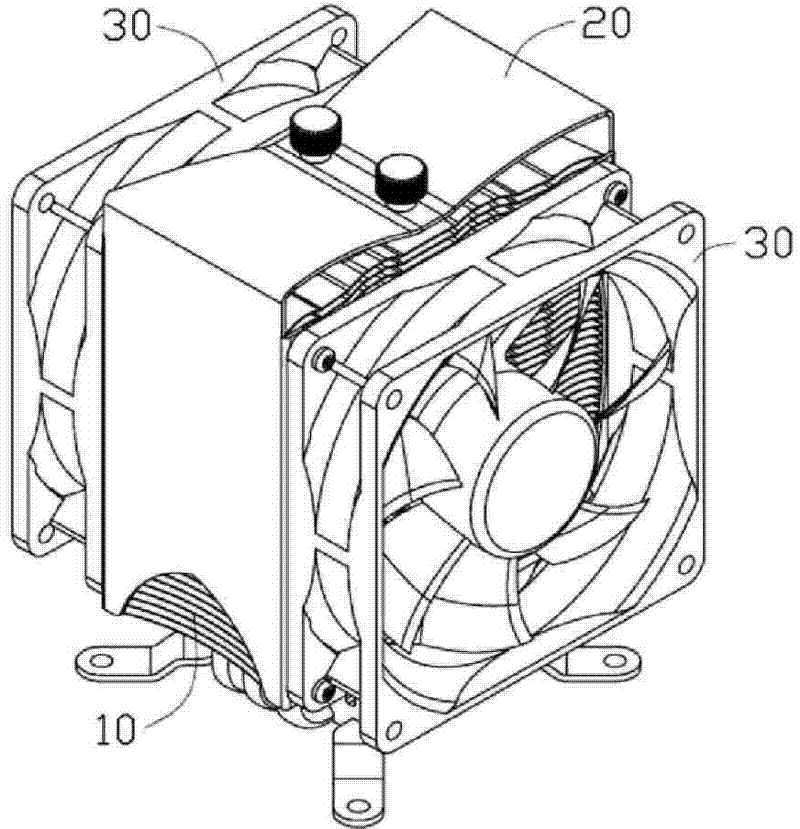

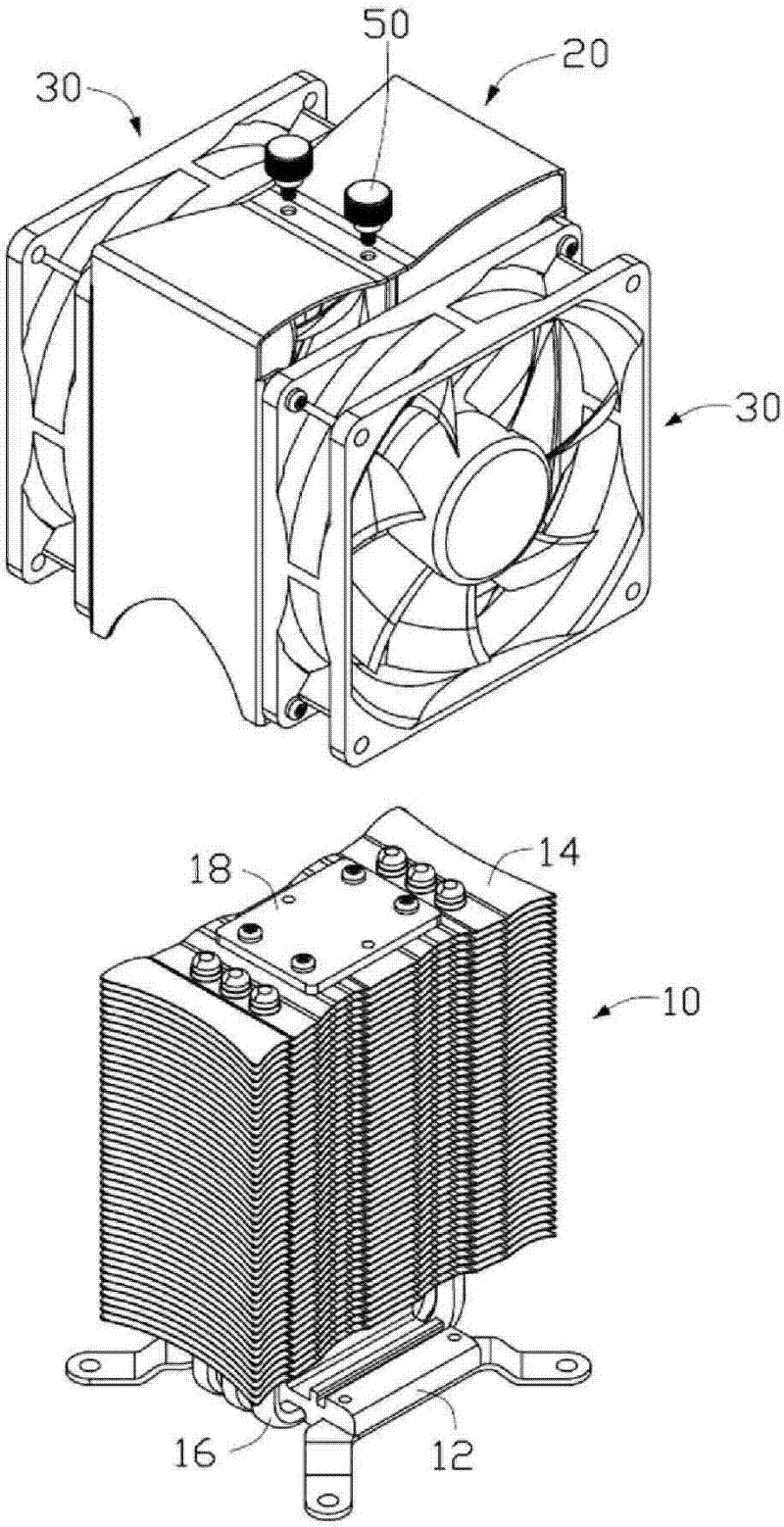

[0013] Please also refer to figure 1 and figure 2 , is the heat dissipation device of the first embodiment of the present invention, the heat dissipation device is installed on a circuit board (not shown in the figure) to dissipate the heat generated by the electronic components (not shown in the figure) on the circuit board. The heat dissipation device includes a radiator assembly 10 , an air guide cover 20 assembled on the radiator assembly 10 , and two fans 30 installed on opposite sides of the air guide cover 20 .

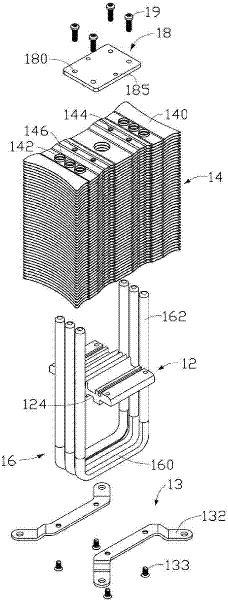

[0014] Please also refer to image 3 , the heat sink assembly 10 includes a heat conduction plate 12, a heat dissipation fin group 14, three heat pipes 16 arranged in parallel for connecting the heat conduction plate 12 and the heat dissipation fin group 14, and a fixing member fixed on the top of the heat dissipation fin group 14 plate 18, wherein:

[0015] The heat conduction plate 12 is roughly in the shape of a rectangular plate, and three parallel groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com