Moisture proofing method for electric heating tube oxidation magnesite powder

A technology of magnesium oxide powder and electric heating tube, which is applied in the direction of the shape of the heating element and the like, can solve the problems of high cost, complicated and cumbersome process, and achieve the effects of low cost, simple process and strong moisture-proof ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

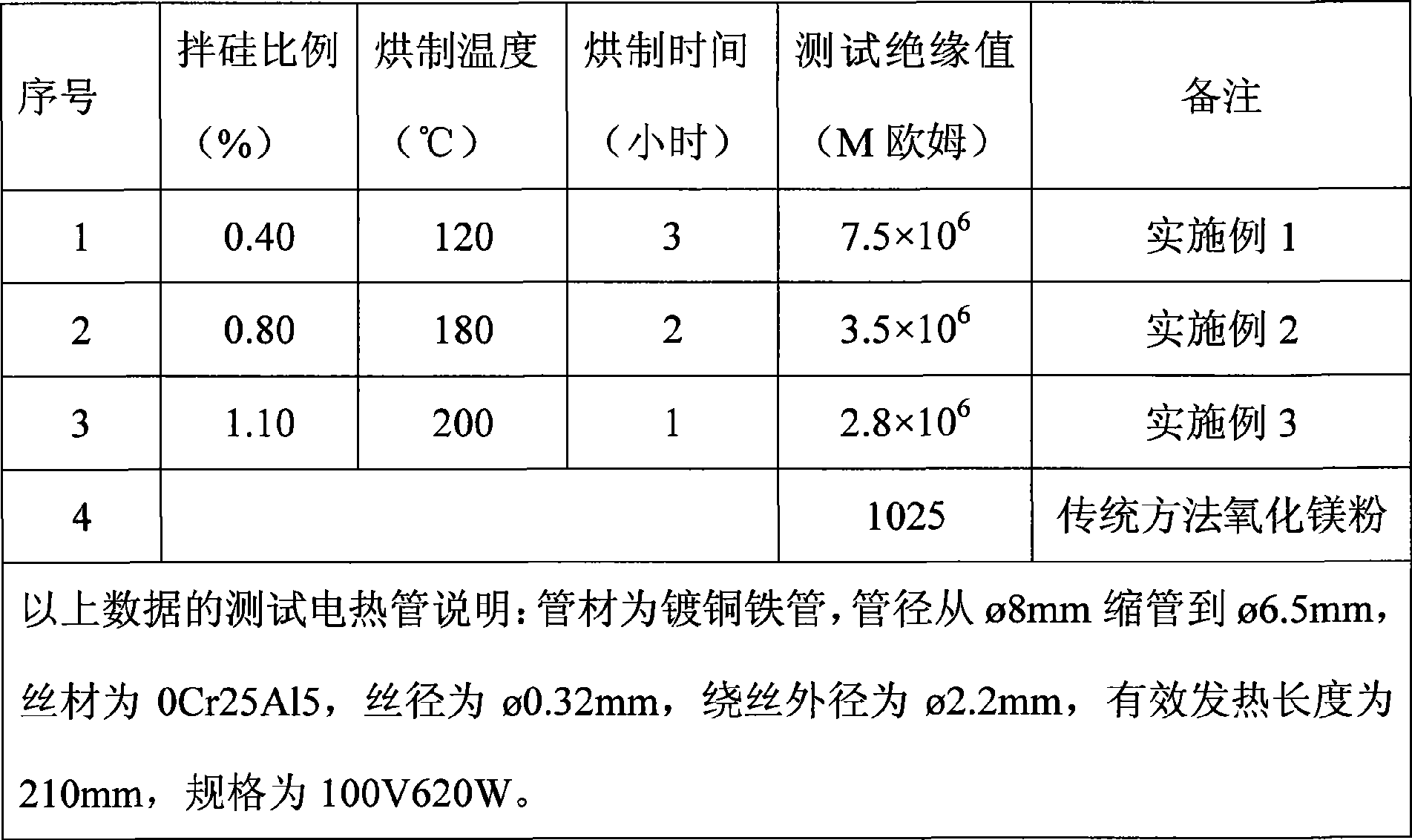

Embodiment 1

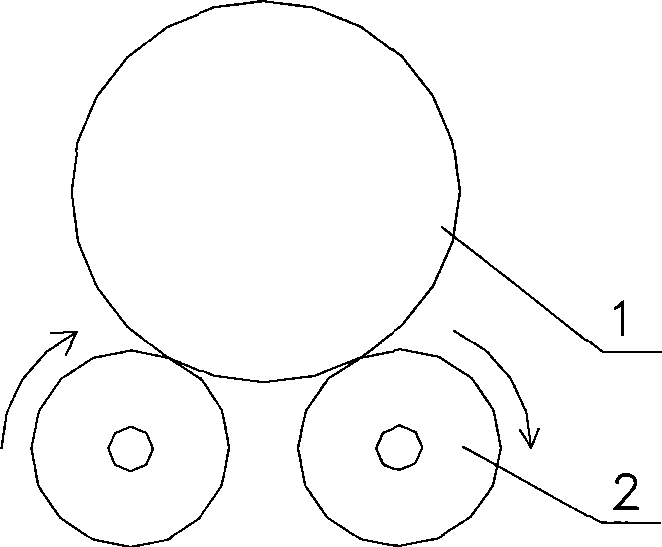

[0022] Such as figure 1 The shown dust-free powder mixing device includes two parallel rollers 2 spaced apart from each other. A stainless steel cylinder 1 in contact with the rollers 2 is placed on the rollers 2. The rotation of the driving roller 2 through the power transmission drives the rotation of the stainless steel cylinder 1. .

[0023] The specific process of the method of the present invention is as follows: the dried silicon powder and magnesium oxide powder filtered through a 60-mesh filter sieve are put into a stainless steel cylinder 1, wherein the silicon powder accounts for 0.4% by weight of the mixture. Then the stainless steel cylinder 1 is covered and sealed, and the inside of the cylinder 1 can be evacuated to improve the mixing effect and shorten the mixing time. Start the roller 2 to make it rotate, and the rotation of the roller 2 drives the rotation of the stainless steel cylinder 1 on it, so that the silicon powder and the magnesium oxide powder are ...

Embodiment 2

[0026] Put the dried silicon powder and magnesium oxide powder filtered through a 70-mesh filter sieve into a stainless steel cylinder 1, wherein the silicon powder accounts for 0.8% by weight of the mixture. Then the stainless steel cylinder 1 is covered and sealed, and the inside of the cylinder 1 can be evacuated to improve the mixing effect and shorten the mixing time. Start the roller 2 to make it rotate, and the rotation of the roller 2 drives the rotation of the stainless steel cylinder 1 on it, so that the silicon powder and the magnesium oxide powder are fully mixed, and the mixing time is 20 minutes. The evenly mixed mixture of magnesium oxide powder and silicon powder is filled into the metal outer tube of the electric heating tube to make the electric heating tube. Put the completed electric heating tube into the oven, close the oven door, keep the electric heating tube at 180°C for 2 hours to complete the baking, and finally complete the production of the electric...

Embodiment 3

[0029] Put the dried silicon powder and magnesium oxide powder filtered through an 80-mesh filter sieve into a stainless steel cylinder 1, wherein the silicon powder accounts for 1.1% by weight of the mixture. Then the stainless steel cylinder 1 is covered and sealed, and the inside of the cylinder 1 can be evacuated to improve the mixing effect and shorten the mixing time. Start the roller 2 to make it rotate, and the rotation of the roller 2 drives the rotation of the stainless steel cylinder 1 on it, so that the silicon powder and the magnesium oxide powder are fully mixed, and the mixing time is 60 minutes. The evenly mixed mixture of magnesium oxide powder and silicon powder is filled into the metal outer tube of the electric heating tube to make the electric heating tube. Put the completed electric heating tube into the oven, close the oven door, keep the electric heating tube at 200°C for 1 hour to complete the baking, and finally complete the production of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com