Head for injecting electrolytic solution

A liquid injection head and electrolyte technology, applied in the direction of circuits, electrical components, battery pack components, etc., can solve the problems of electrolyte injection volume deviation, increase electrolyte volatilization, affect battery liquid injection accuracy, etc., and improve battery performance , simple structure, reduce the effect of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

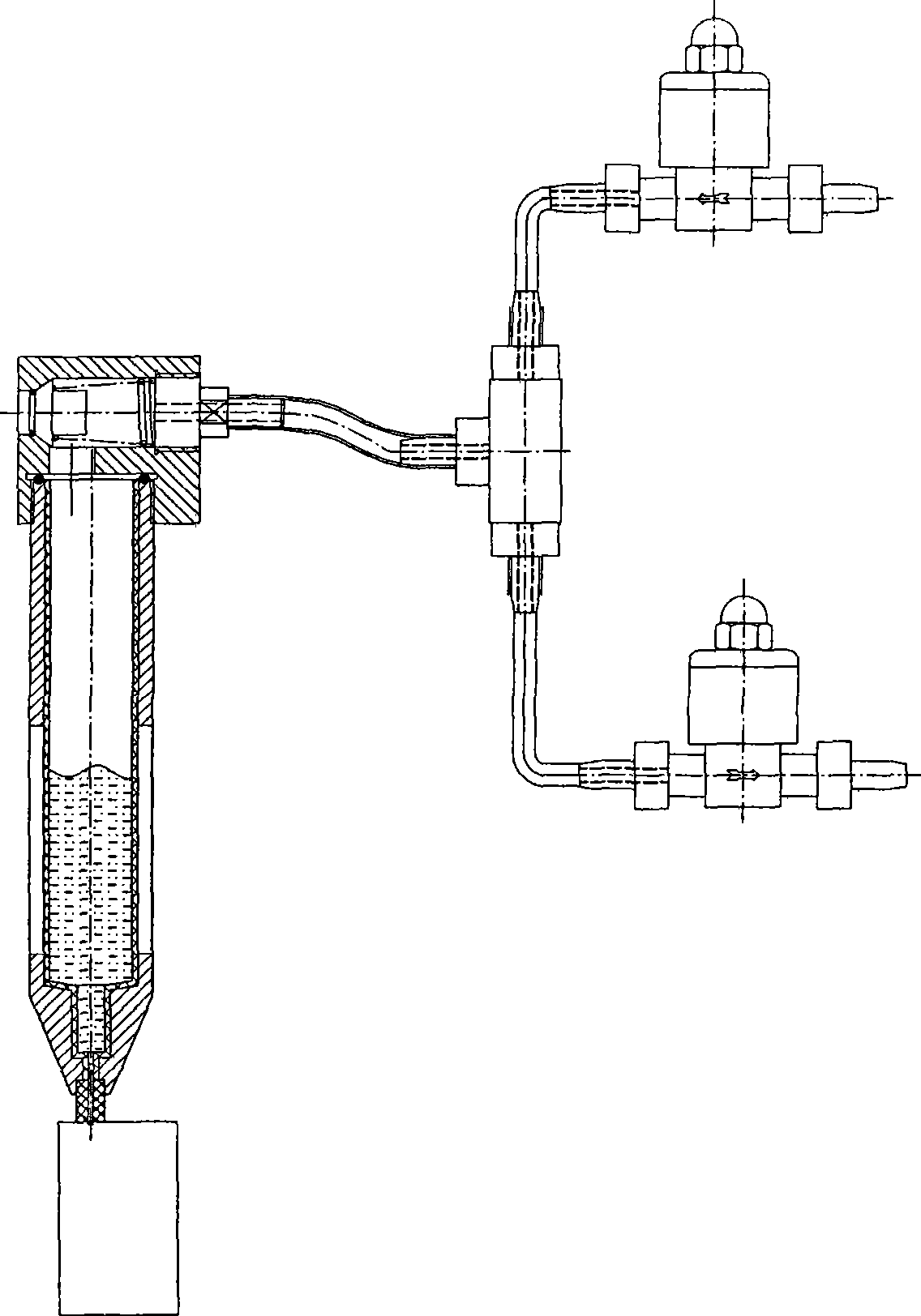

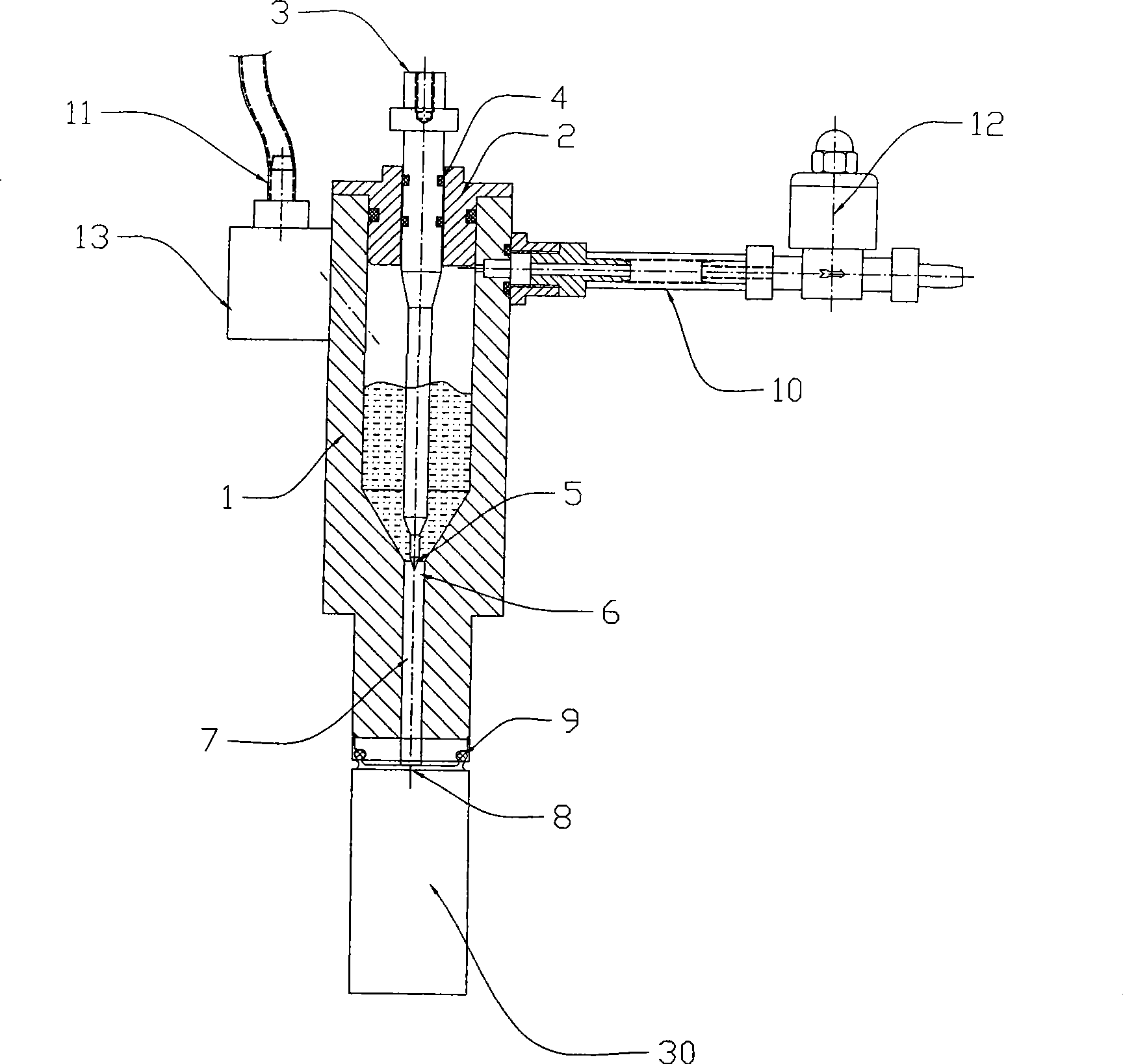

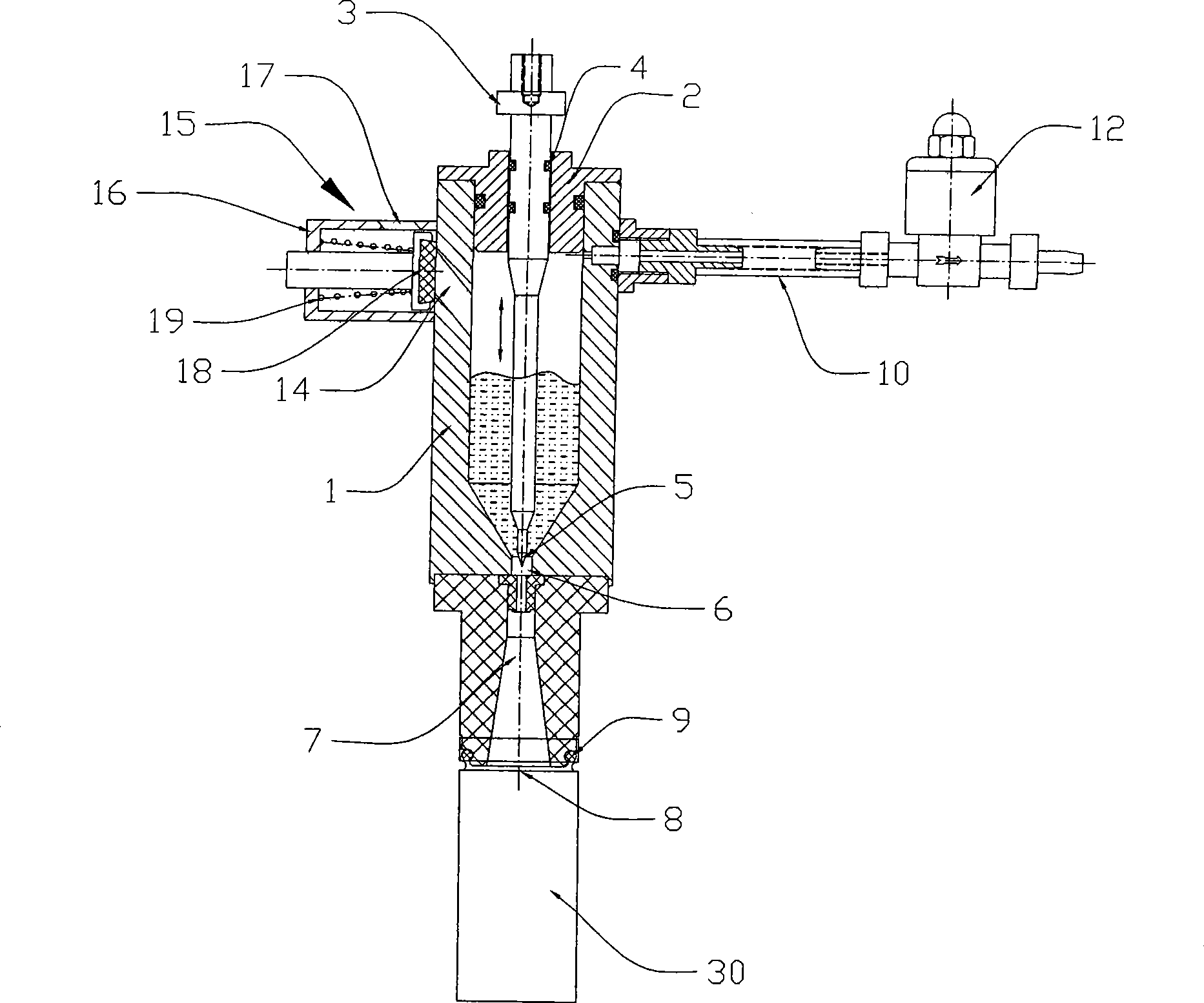

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] as attached figure 2 As shown, the electrolyte injection head of the present invention includes a cylindrical cavity 1, a guide sleeve 2, a needle valve 3, a sealing ring 4, a valve port 6, and a channel 7. The cylindrical cavity is provided with a vacuum pipeline connection port, and the tube A liquid injection pipeline connection port is provided on the cylindrical cavity, and a vacuum pipeline 10 communicating with it is installed on one side of the cylindrical cavity. An injection pipeline 11 communicating with the cavity is also installed, and a restrictor valve 13 for controlling its on-off is also arranged on the injection pipeline. A guide sleeve is installed on the top of the cylindrical cavity, the needle valve is inserted into the guide sleeve, the needle valve can move up and down in the guide sleeve, a sealing ring 4 is installed between the needle val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com