Flexible film-like solar cell composite layer

A solar cell, film-like technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced interlayer interface adhesion, reduced power generation output, etc., and achieve the effect of preventing power generation output from reducing and preventing moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

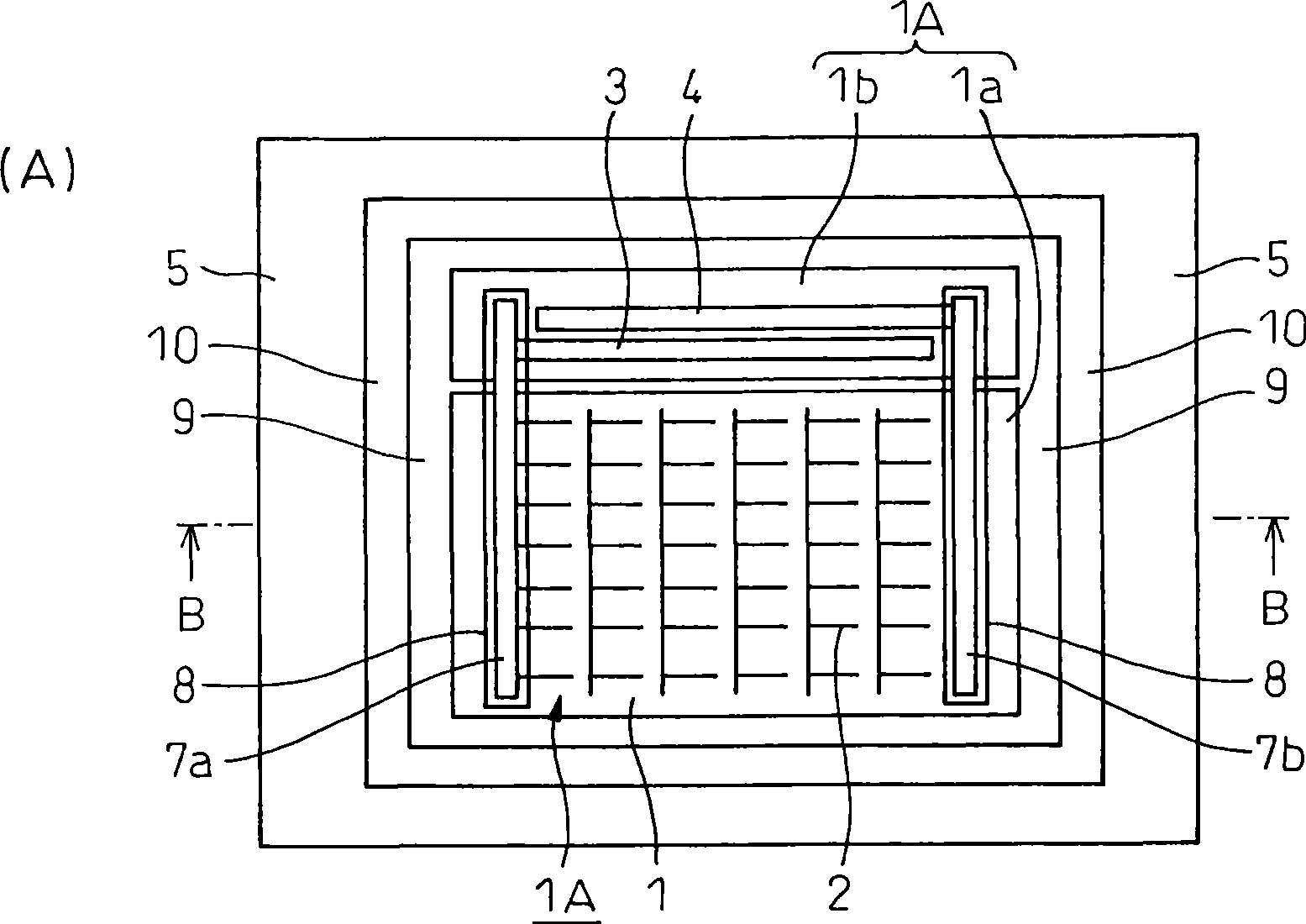

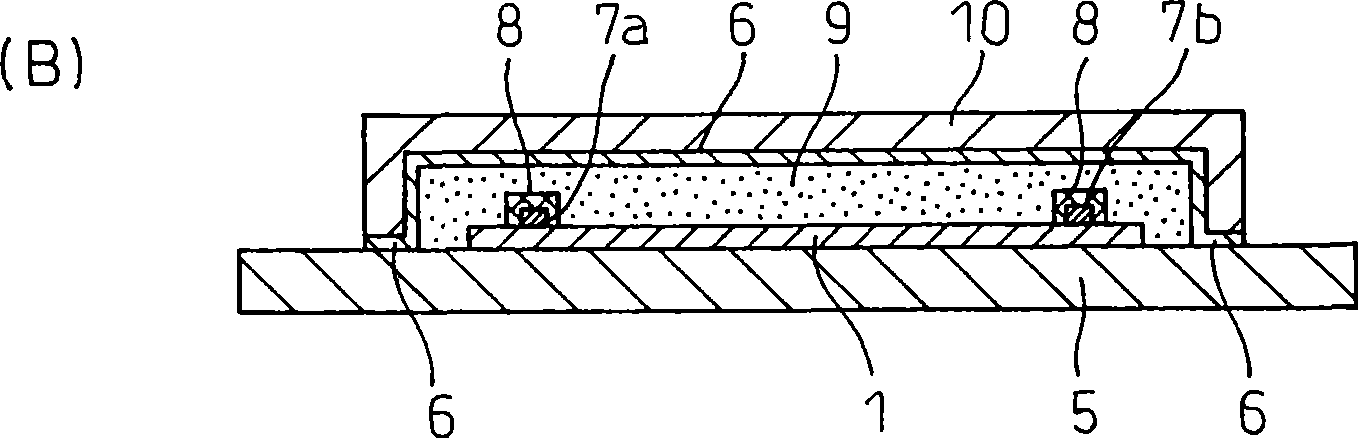

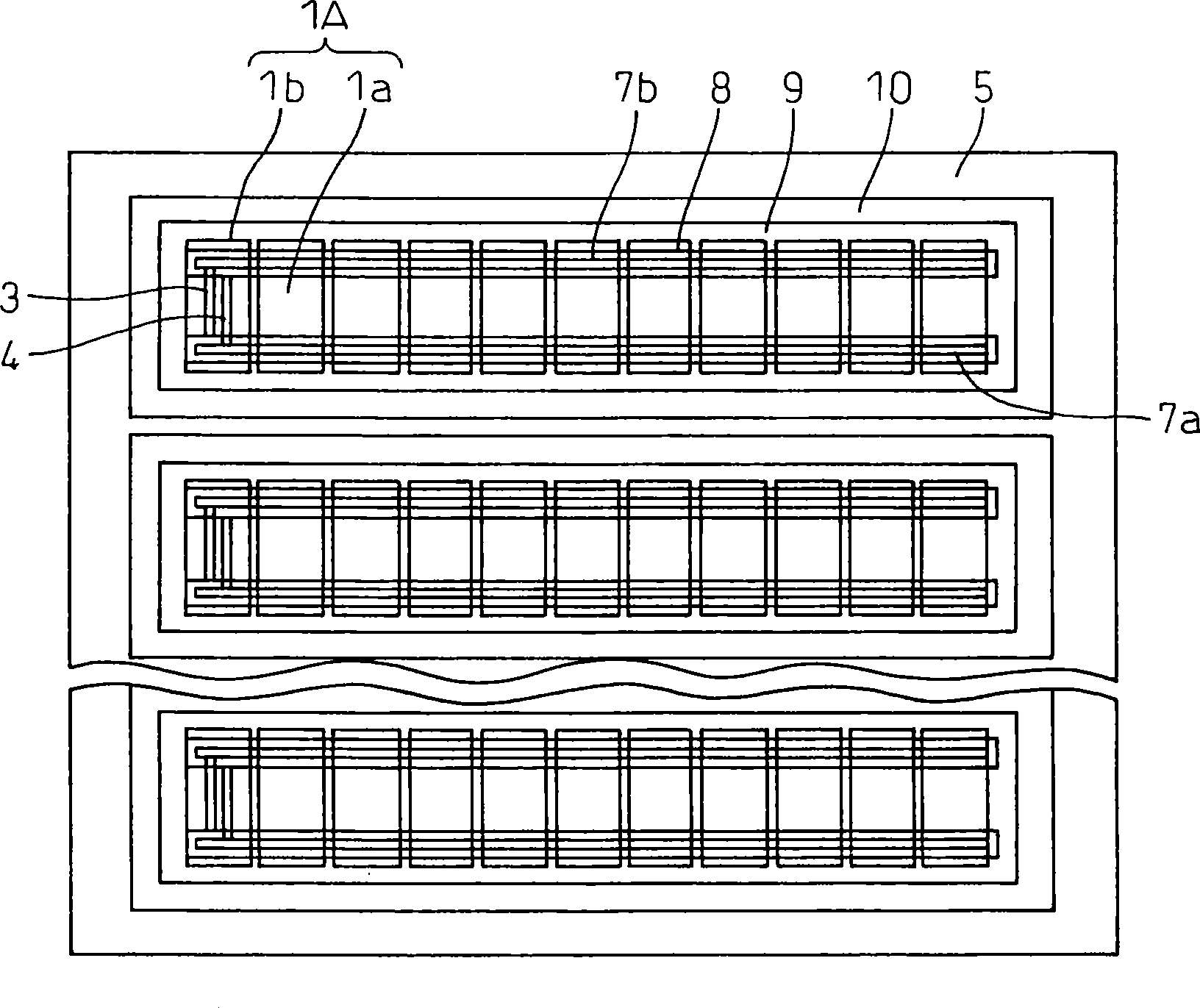

Method used

Image

Examples

Embodiment 1

[0135] Arrange 10 solar cell units with a width of 260 mm and a length of 80 mm in series, and then assemble them with a collector connector to form a flexible solar cell module. The adhesive resin described above was laminated on the central part of a flexible waterproof supporting film material with a width of 1000 mm and a length of 1500 mm, and bonded and integrated.

[0136] As the adhesive resin, an acrylic resin cross-linked by a coupling agent compound (such as an epoxy-based silane coupling agent) and an epoxy resin (such as a urethane-modified epoxy resin) is used.

[0137] In addition, as the fiber fabric for the base fabric of the flexible waterproof supporting membrane material, a base fabric plain weave (mass per unit area: 160 g / m 2 , Density: 40 warps / 25.4mm, 50 wefts / 25.4mm). Furthermore, the following flexible waterproof resin film was pasted on the base fabric of the above-mentioned flexible waterproof supporting film material.

[0138] As a flexible water...

Embodiment 2

[0160] A flexible film-shaped solar cell multilayer was produced in the same manner as in Example 1 and used for testing. However, the flexible surface protective film layer was formed with an ethylene-tetrafluoroethylene copolymer film (50 µm in thickness) having an area of 150% with respect to the area of the solar cell layer.

[0161] The test results are shown in Table 1.

Embodiment 3

[0163] A flexible film-shaped solar cell multilayer was produced in the same manner as in Example 1 and used for testing. However, the flexible surface protection film layer was formed with a polyvinyl fluoride film (thickness: 50 μm) having an area of 150% with respect to the area of the solar cell layer.

[0164] The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com