Hydro-upgrading method for diesel distillate

A hydrogenation modification and fractionation technology, which is applied in refining to remove heteroatoms, etc., can solve the problems of limited increase in cetane number, difficult operation, complicated process, etc., to achieve large production flexibility, simple device process, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

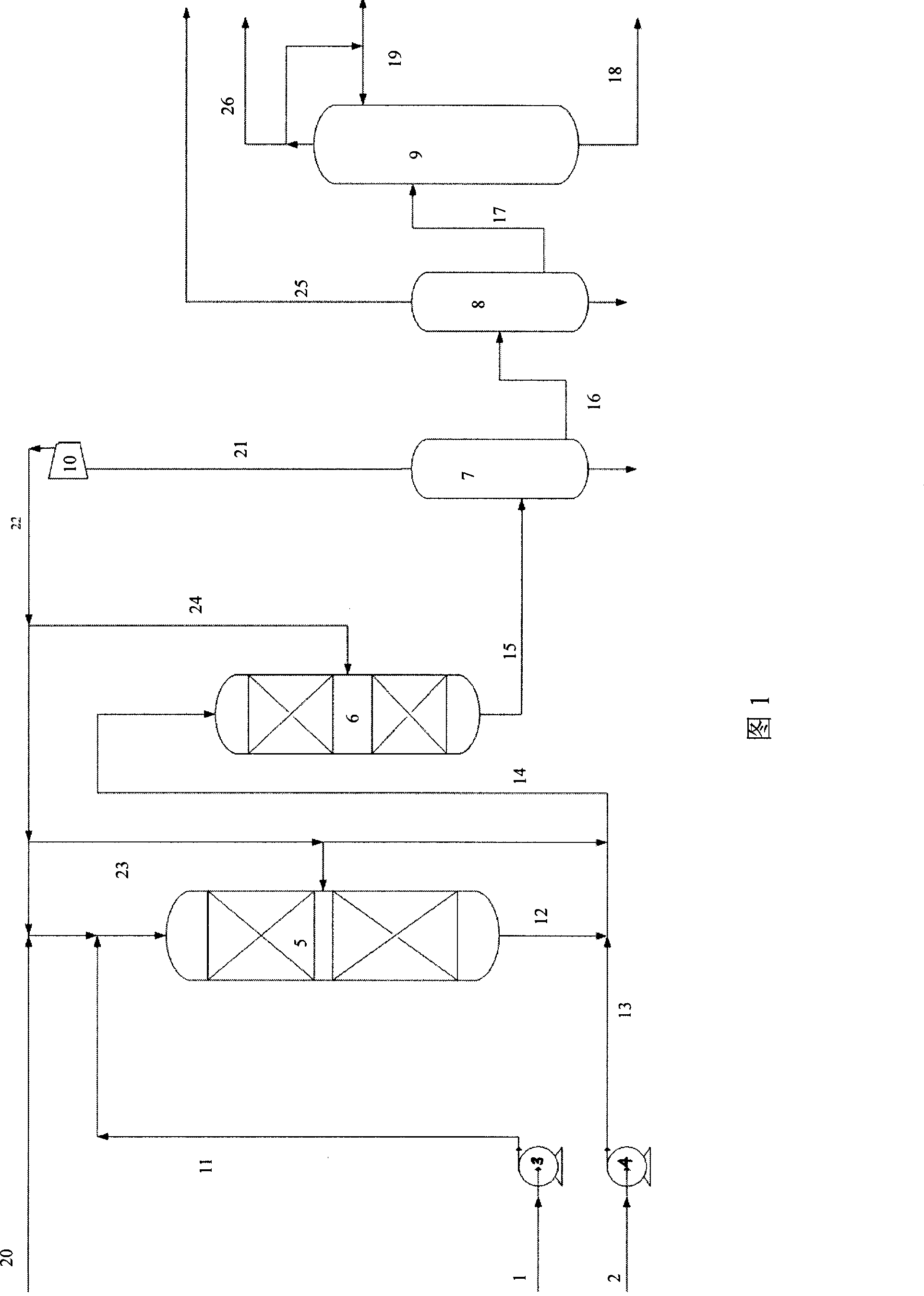

[0040]According to a preferred embodiment of the present invention, the hydro-upgrading method of the diesel fraction can be carried out according to the method shown in FIG. 1 . As shown in Figure 1, the diesel oil fraction 1 with a total aromatics content of not less than 35% by weight passes through the raw oil pump 3, and after preheating, it is counted as 11 and mixed with hydrogen-rich gases 20 and 22 to enter the first reactor 5, and is sequentially mixed with the first reactor 5. The hydrorefining catalyst, the second hydrorefining catalyst and the hydrorefining catalyst are contacted to perform deep desulfurization, denitrogenation, dearomatization and cetane number improvement reactions to obtain the contacted product 12. The total amount of the contacted product is The aromatics content is below 35% by weight. The diesel fraction 2 with a total aromatics content lower than 35% by weight passes through the raw oil pump 4, counts as 13 after preheating, mixes with the...

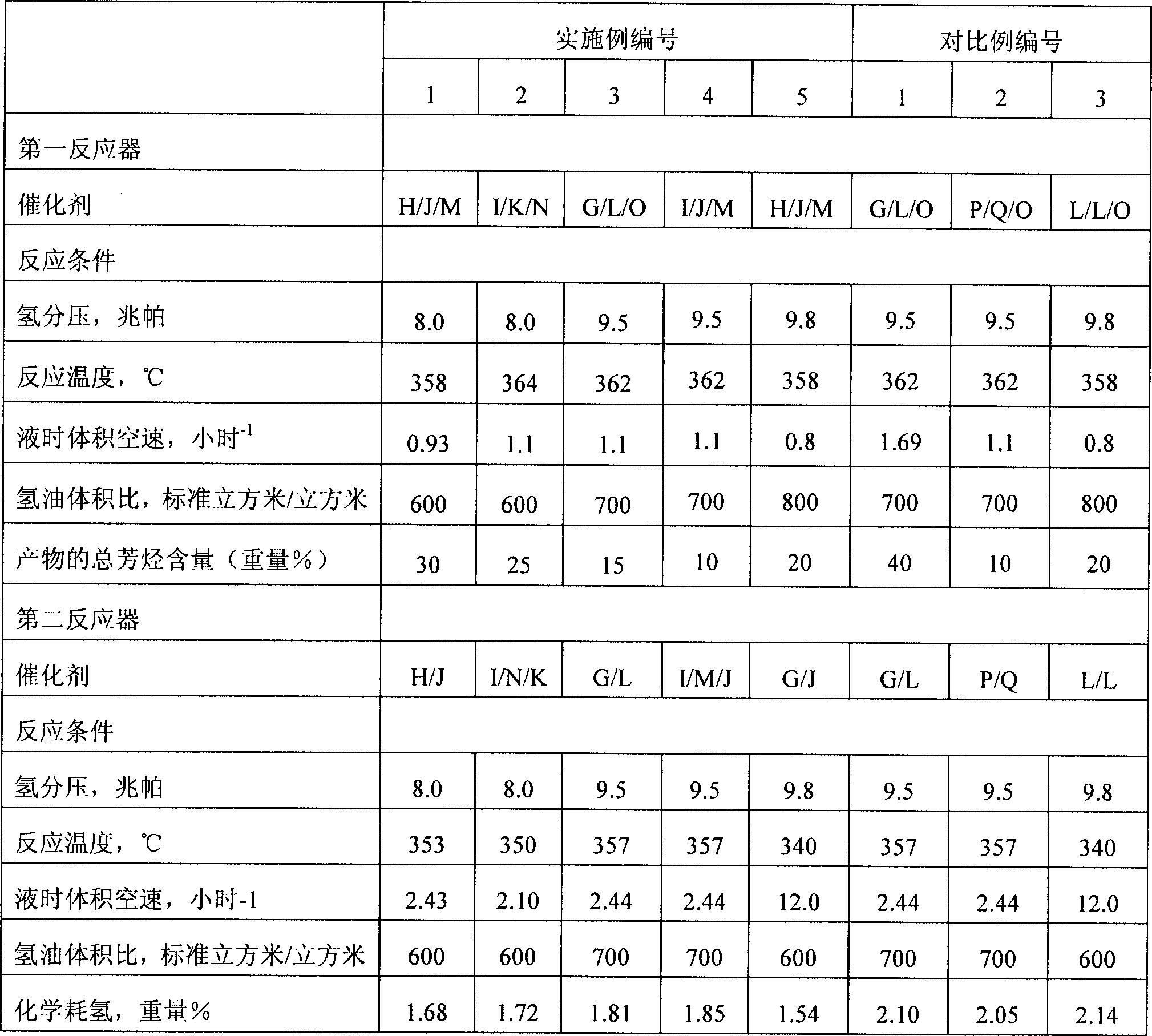

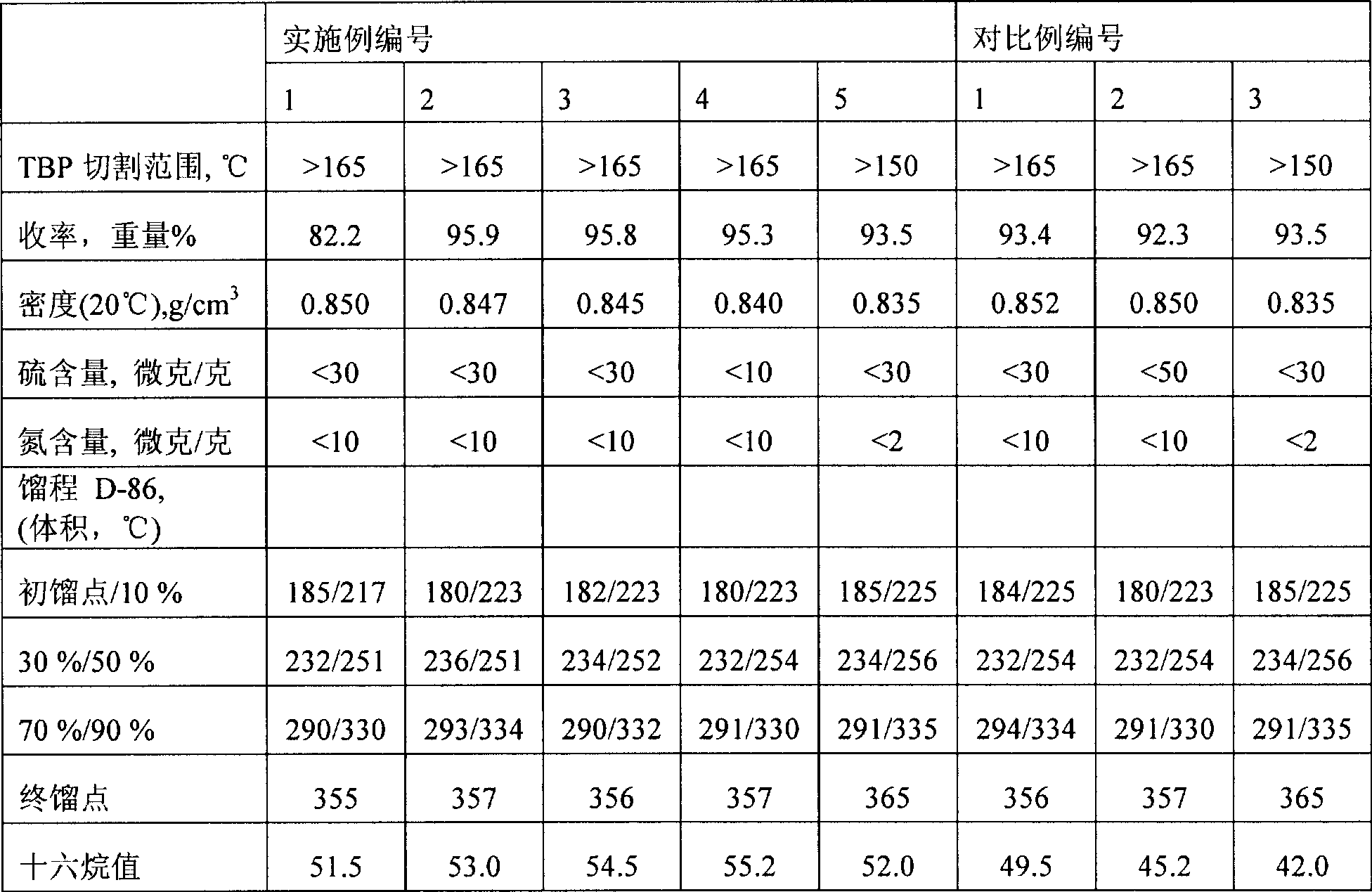

Embodiment 1

[0045] This example is used to illustrate the diesel fraction hydro-upgrading method provided by the present invention.

[0046] The raw material oil C, which accounts for 54.5% by weight of the total feed, is contacted with hydrogen-rich gas (the hydrogen content is 80% by volume), and enters the first reactor after being preheated by the heating furnace, and is sequentially mixed with the first hydrotreating catalyst H (for the second 20% by volume of the second hydrorefining catalyst J in one reactor), the second hydrorefining catalyst J, and the hydrorefining catalyst M are contacted, and the volume ratio of the second hydrorefining catalyst J and the hydrorefining catalyst M is 4:1. The raw material oil A which accounts for 15.5% by weight of the total feed amount and the feed oil B which accounts for 30% by weight of the total feed amount are mixed and preheated through a heating furnace, and then mixed with the first reactor effluent and entered into the second reactor,...

Embodiment 2

[0048] This example is used to illustrate the diesel fraction hydro-upgrading method provided by the present invention.

[0049] The raw material oil C, which accounts for 75% by weight of the total feed amount, is contacted with hydrogen-rich gas (the hydrogen content is 60% by volume), and enters the first reactor after being preheated by the heating furnace, and is sequentially mixed with the first hydrotreating catalyst I (for the second 10% by volume of the second hydrorefining catalyst J of a reactor), the second hydrorefining catalyst K, and the hydrorefining catalyst N are contacted, and the volume ratio of the second hydrorefining catalyst K and the hydrorefining catalyst N is 2:1. Accounting for 25% by weight of the total feed amount, raw oil B and hydrogen-rich gas are mixed and preheated by a heating furnace, then mixed with the effluent of the first reactor and entered into the second reactor, and sequentially mixed with the first hydrotreating catalyst I (for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com