Environment protective emulsive explosive composite emulsifying agent

A technology of compound emulsifier and emulsified explosive, which is used in explosives, non-explosive/non-thermal components, offensive equipment, etc., can solve the problems of inability to meet market demand and single type of emulsifier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

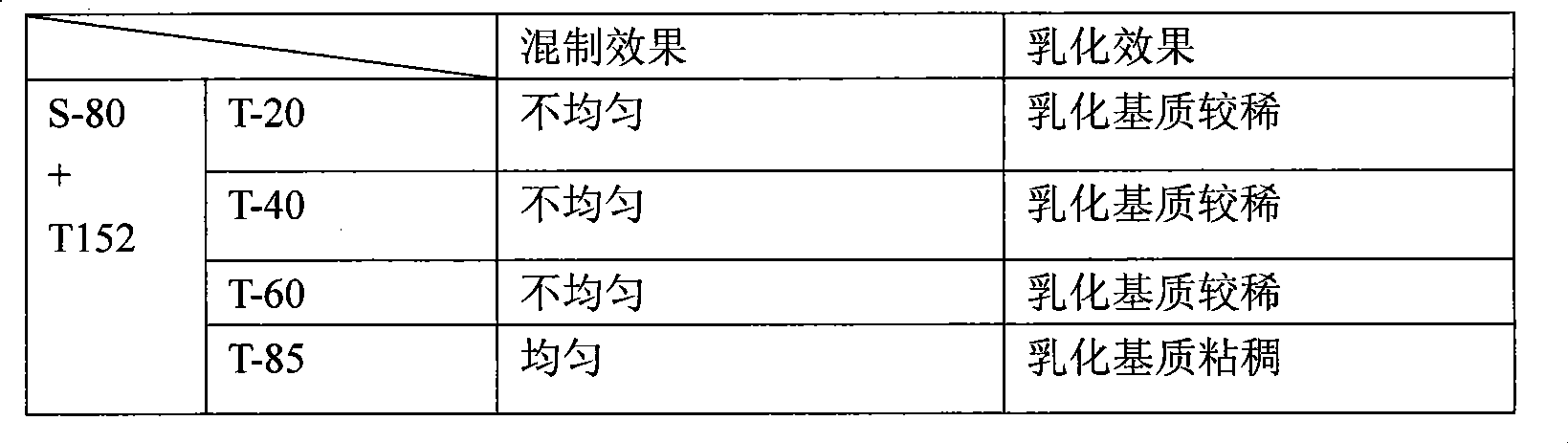

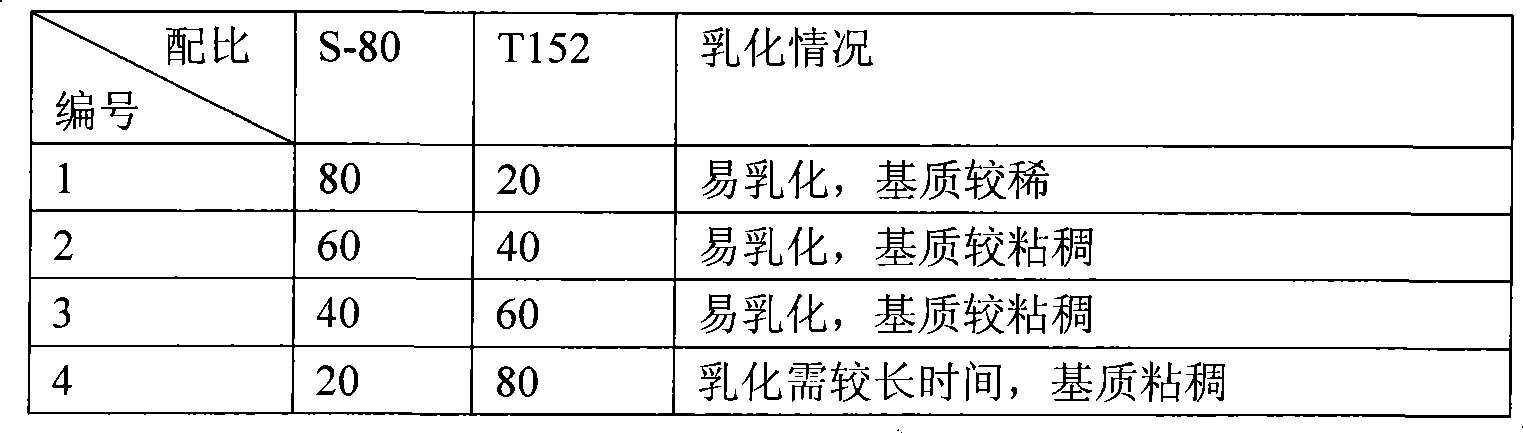

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of environmental protection emulsion explosive composite emulsifier is made up of the raw material of following weight ratio, 30 parts of double polyisobutylene succinimide (T-152), sorbitan monooleate (S- 80) 65 parts, polyoxyethylene sorbitan trioleate (T-85) 3 parts,

[0029] Stir and mix the sorbitan monooleate (S-80) and sorbitan polyoxyethylene ether trioleate (T-85) in the above weight ratio at 100-110°C, and then Stir and mix the mixture of the two and double polyisobutylene succinimide (T152) at 100-110°C.

Embodiment 2

[0030] Embodiment 2: A kind of environment-friendly emulsified explosive composite emulsifier is made up of the raw materials of following weight ratio, 40 parts of double polyisobutylene succinimide (T152), sorbitan monooleate (S-80) 50 parts, 6 parts of polyoxyethylene sorbitan trioleate (T-85),

[0031] Stir and mix the sorbitan monooleate (S-80) and sorbitan polyoxyethylene ether trioleate (T-85) in the above weight ratio at 100-110°C, and then Stir and mix the mixture of the two and double polyisobutylene succinimide (T152) at 100-110°C.

Embodiment 3

[0032] Embodiment 3: A kind of environment-friendly emulsified explosive compound emulsifier is made up of the raw material of following weight ratio, 35 parts of double polyisobutylene succinimide (T152), sorbitan monooleate (S-80) 59 parts, 5 parts of polyoxyethylene sorbitan trioleate (T-85),

[0033] Stir and mix the sorbitan monooleate (S-80) and sorbitan polyoxyethylene ether trioleate (T-85) in the above weight ratio at 100-110°C, and then Stir and mix the mixture of the two and double polyisobutylene succinimide (T152) at 100-110°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com