Enzyme preparation biological organic fertilizer

A bio-organic fertilizer and enzyme preparation technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of poor fertilizer efficiency and failure of bacterial preparation bio-organic fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

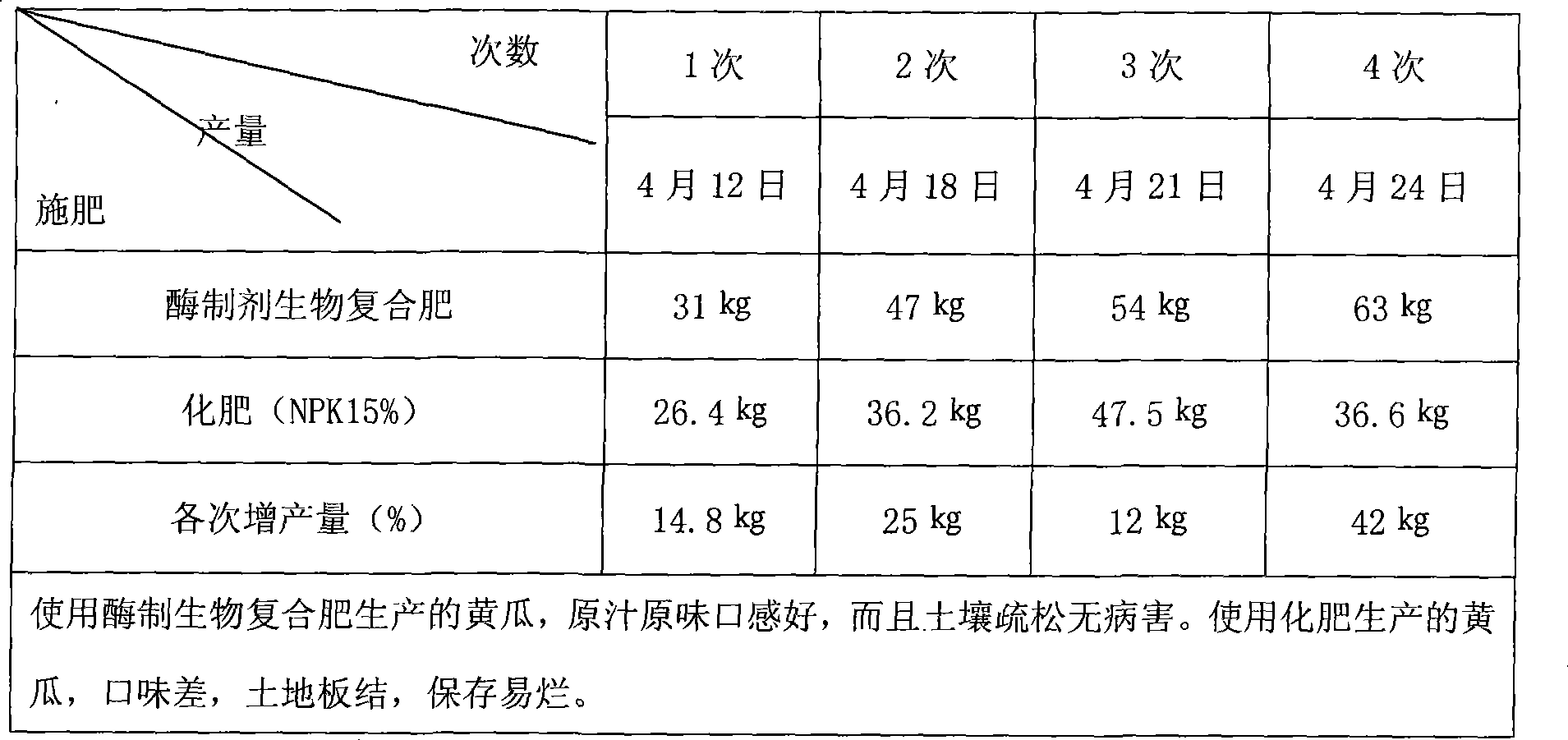

Image

Examples

Embodiment 1

[0026] First, ferment poultry manure at a temperature above 60°C for 7-10 days, and overturn it three times during the fermentation process; take 98 parts of the fully fermented poultry manure and add 2 parts of biological compound enzymes, namely nitrogenase 30%, phosphatase 20%, potassium-dissolving enzyme 15%, plant-promoting enzyme 14%, heavy metal-adsorbing enzyme 12%, and disease-preventing enzyme 9%, after being fully mixed, granulated and packaged, the finished product can be directly fertilized into the soil.

Embodiment 2

[0028] Firstly steam-explode and pulverize the stalk and ferment it for 7-10 days above the temperature of 60° C., and overturn it three times during the fermentation process; take 95 parts of the stalk after it has been fully fermented and then add 5 parts of biological compound enzyme, i.e. nitrogenase 15%, decomposing 10% phosphatase, 8% potassium decomposing enzyme, 7% plant-promoting enzyme, 6% heavy metal-adsorbing enzyme, and 5% disease-preventing enzyme. After fully mixing, granulate and package the finished product, which can be directly fertilized into the soil.

Embodiment 3

[0030] First, ferment the peat soil at a temperature above 60°C for 7-10 days, and overturn it three times during the fermentation process; take 93 parts of the fully fermented peat soil and add 7 parts of biological compound enzymes, namely nitrogenase 28% and phosphatase 18% , 13% potassium-dissolving enzyme, 12% plant-promoting enzyme, 11% heavy metal-adsorbing enzyme, and 8% disease-preventing enzyme. After fully mixing, granulate and package the finished product, which can be directly fertilized into the soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com