Eccentric crankshaft punching machine

A crankshaft punching and eccentric technology, applied in the field of mechanical processing equipment, can solve the problems of large volume, high noise, difficult large-area thin plate cutting, etc., and achieve the effect of small volume, low noise and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

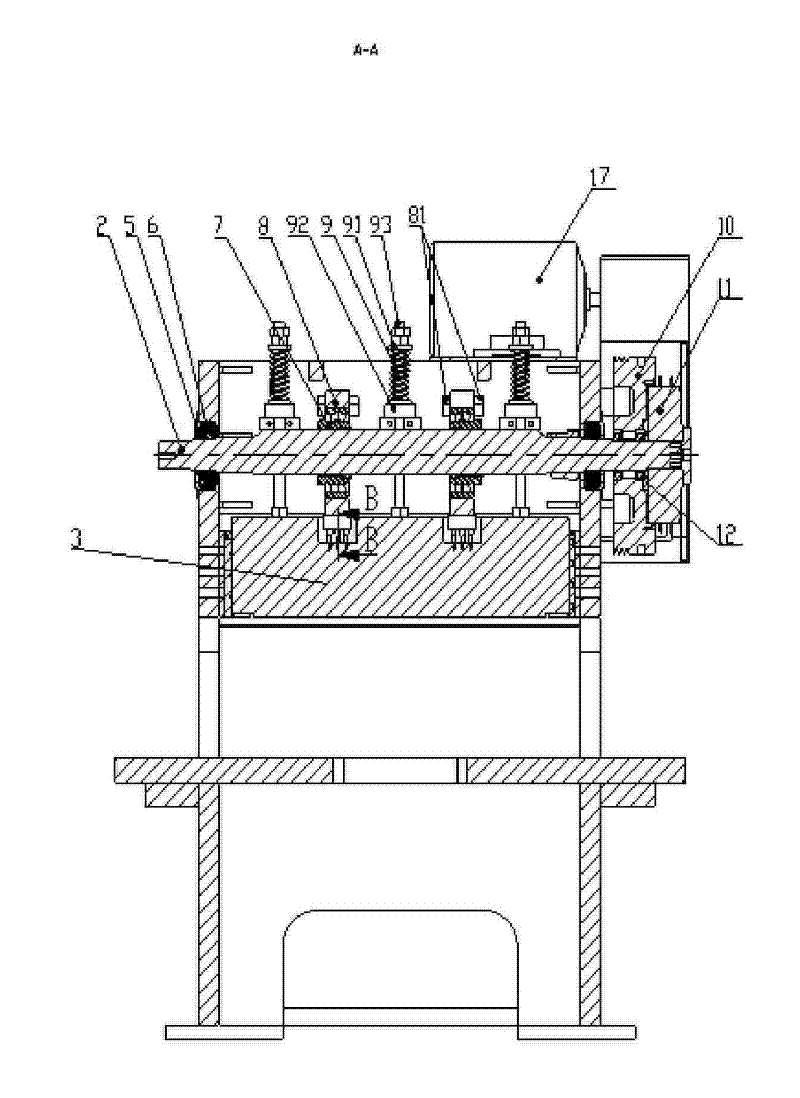

[0022] Embodiment: a kind of eccentric crankshaft press of the present invention, as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , shown in accompanying drawing 5, it comprises frame 1, workbench 4, drive motor 17 and the crankshaft 2 that is connected with it by transmission mechanism, be located at crankshaft 2 below and the slide block 3 of bottom installation mould.

[0023] The crankshaft 2 is an eccentric shaft, and its eccentric part is covered with a rolling body 7, and the outer peripheral surface of the rolling body 7 forms a rigid contact with the slider 3 directly or through a transition piece, which can transmit a downward force. The rolling elements 7 are set as two sets on the crankshaft 2 . The crankshaft 2 is made in one piece, and its eccentric part is formed by a cylinder deviated from the axis line on the shaft body. The rolling element 7 is a roller self-aligning bearing, and its inner ring is fixed on the crankshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com