Novel electronic horn for automobile and manufacturing method thereof

A technology for electronic horns and vehicles, which is applied in the direction of sound-generating devices and instruments, and can solve problems such as reduced horn life, ablation, and contact oxidation, and achieves the effects of reduced workshop management costs, simplified process, and reduced withstand voltage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

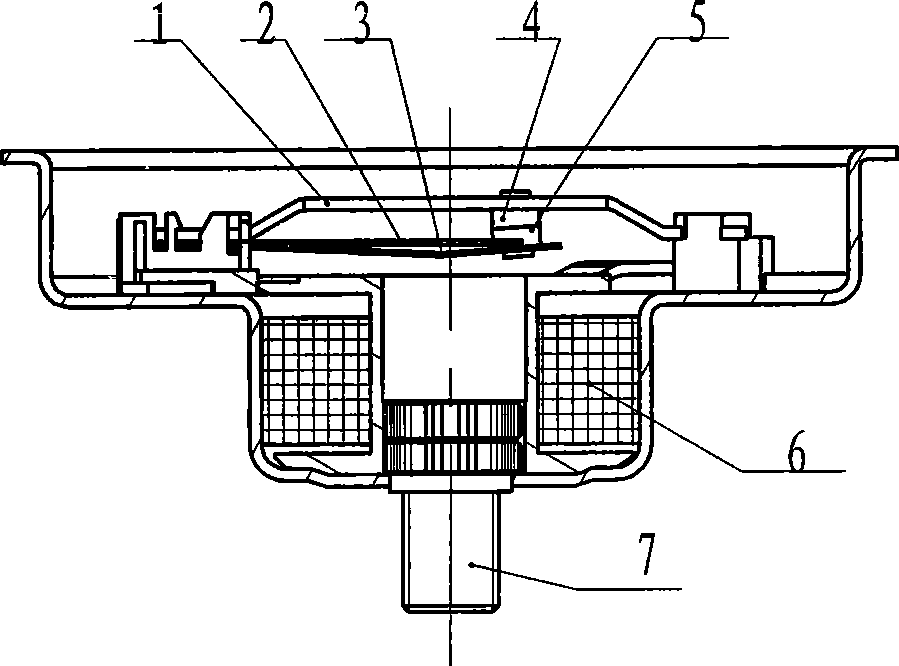

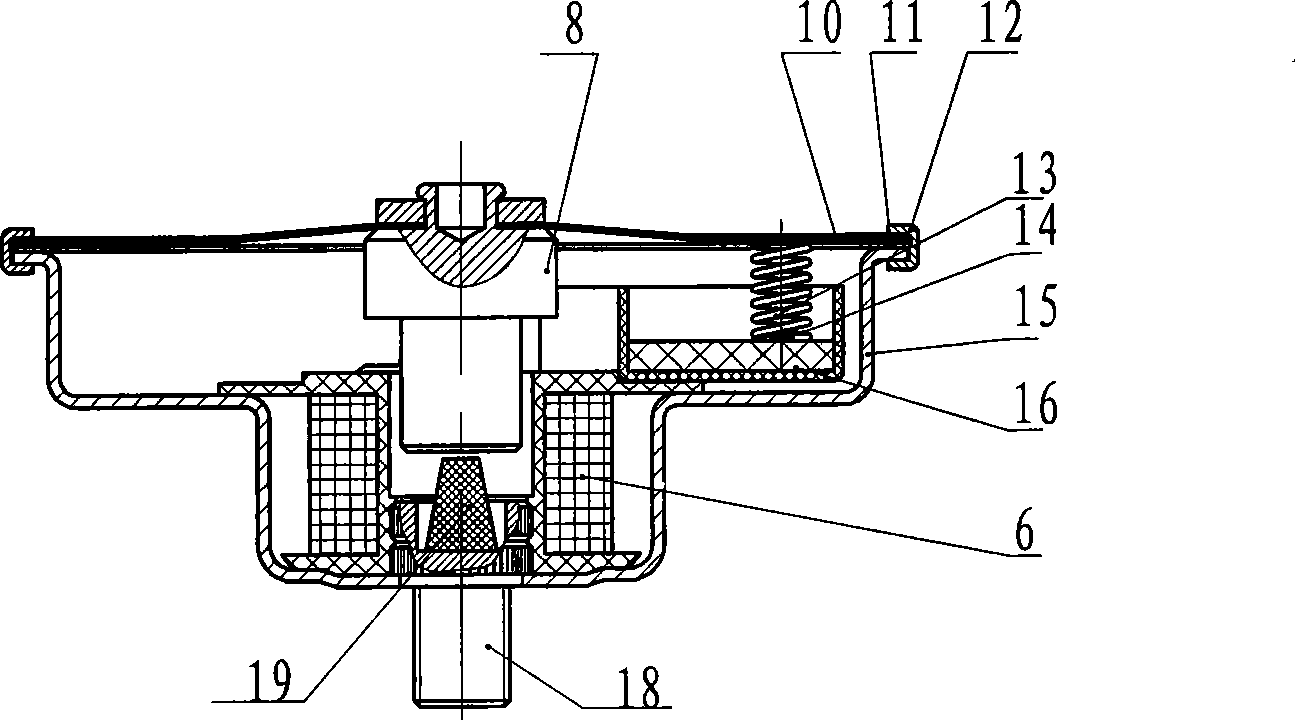

[0029] In this new type of automotive electronic horn, (see attached figure 2 ), which consists of: diaphragm 10, moving armature 8, static armature 18, conductive rubber 19, pressure ring 12, housing 15 and electronic switch circuit 16. The diaphragm 10 is connected with the movable armature 8, and the outer ring of the diaphragm 10 has a sealing insulating ring 11, and the diaphragm 10 is connected with the electronic switch circuit 16 through an electrical lead-out device. A counterbore is drilled at the center above the static armature 18, and a conductive rubber 19 is installed in the counterbore. The moving armature 8 and the static armature 18 are connected and disconnected through the conductive rubber 19 . The conductive rubber 19 is connected with the housing 15 through the static armature 18 . The diaphragm 10 and the sealing insulating ring 11 are riveted together with the casing 15 through the pressure ring 12 , but the diaphragm 10 and the casing 15 are insula...

Embodiment 2

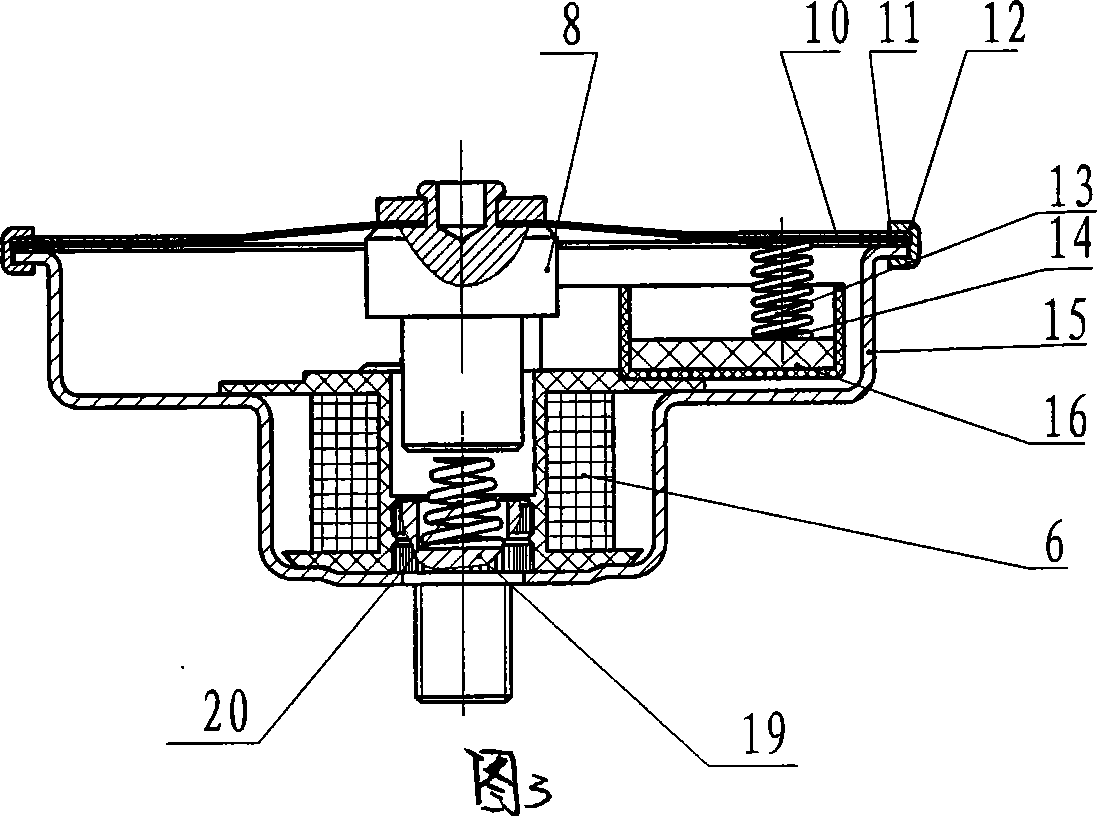

[0034] Similar to Embodiment 1 (see accompanying drawing 3), the difference is that the conductive rubber 19 in Embodiment 1 is changed into a tower spring 20.

[0035] In this novel vehicle electronic horn structure, a counterbore is drilled at the center above the static armature 19, and a tower spring 20 is installed in the counterbore. The static armature 19 is connected with the tower spring 20 by welding. The moving armature 8 and the static armature 19 are connected and disconnected through the tower spring 20 . The tower spring 20 is connected with the housing 15 through the static armature 19 .

[0036] In the electronic switch circuit 16, in the process of turning on and off the circuit, the tower spring 20 on the moving armature 8 and the static armature 19 reciprocally contacts and leaves, thereby driving the diaphragm 10 to vibrate and causing the horn to sound .

Embodiment 3

[0038] Similar to Example 1, (see attached Figure 4 ), the difference is that the conductive rubber 19 in the embodiment 1 is changed into a V-shaped shrapnel 22, and a counterbore is drilled at the center of the static armature 21 in the embodiment 1 and changed into a through groove for milling.

[0039] In this new type of vehicle electronic horn structure, a through groove is milled on the static armature 21 along the center line, and the V-shaped shrapnel 22 is welded in the middle of the groove, and the two ends of the V-shaped shrapnel 22 expose the static armature 21 of the upper surface. The static armature 21 is connected with the V-shaped shrapnel 22 by welding. The moving armature 8 and the static armature 21 are connected and disconnected through the V-shaped shrapnel 22 . The V-shaped shrapnel 22 is connected to the housing 15 through the static armature 21 .

[0040] In the electronic switch circuit 16, in the process of turning on and off the circuit, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com