High precision gas leakage working position separating detection device

A gas leakage and detection device technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problems of low detection efficiency and low detection accuracy, and achieve improved detection accuracy, Effect of improving detection efficiency, improving detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

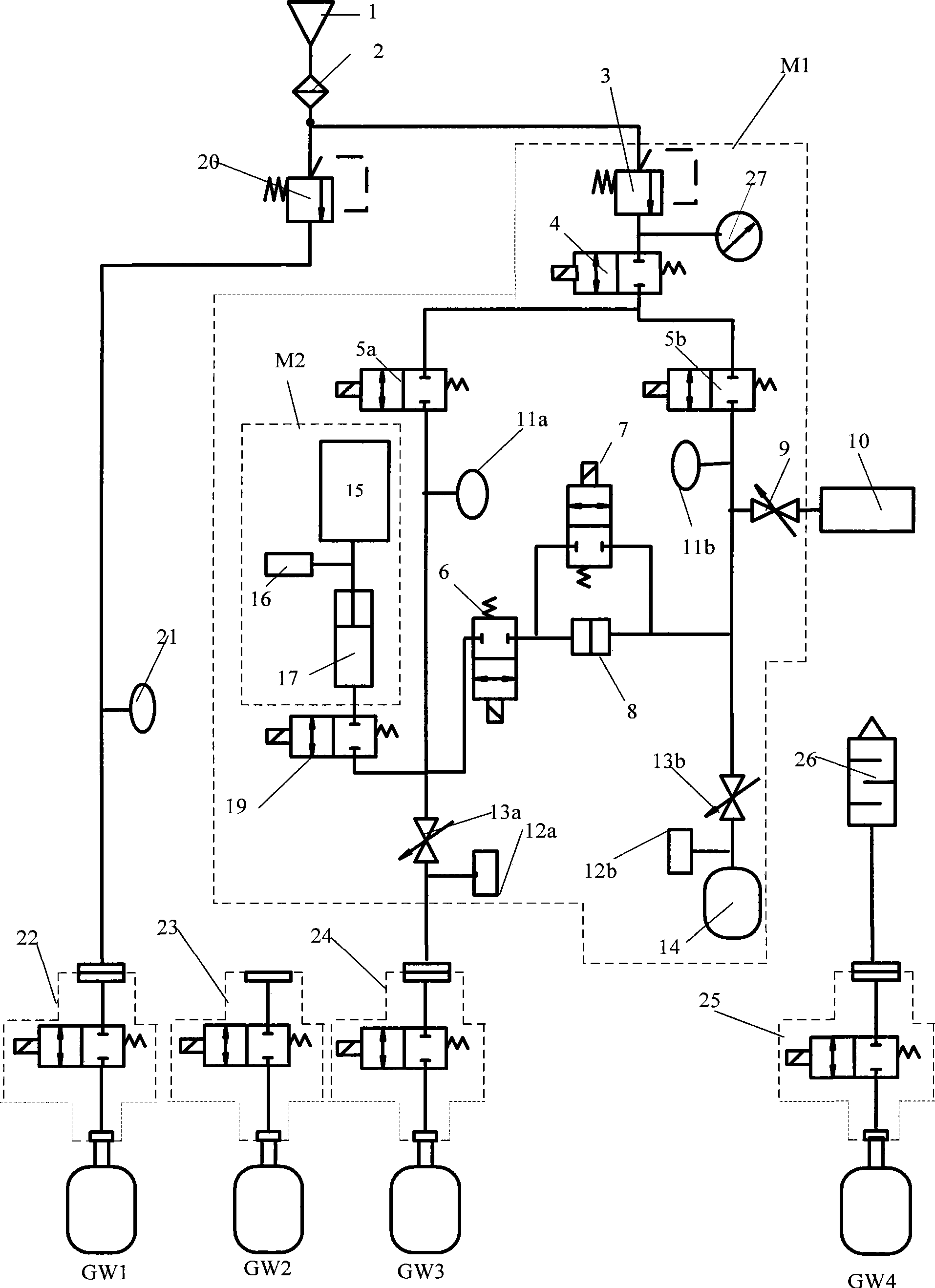

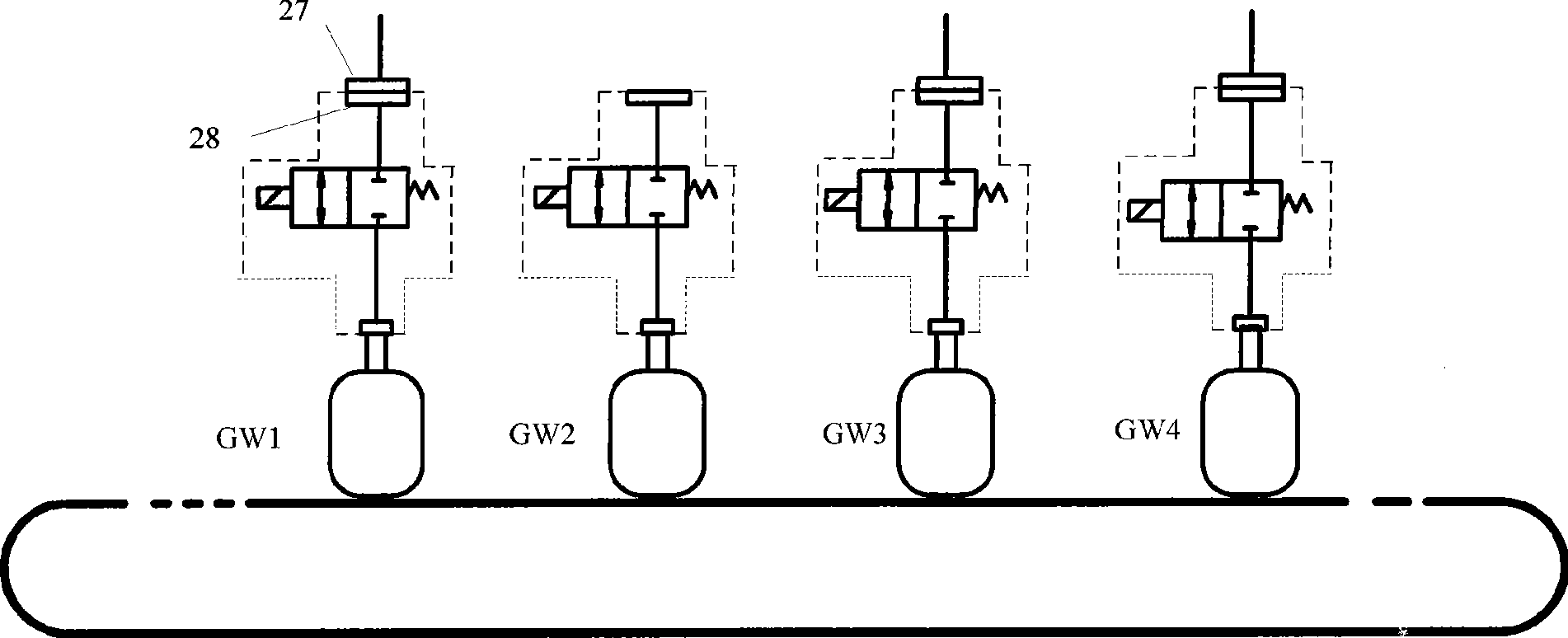

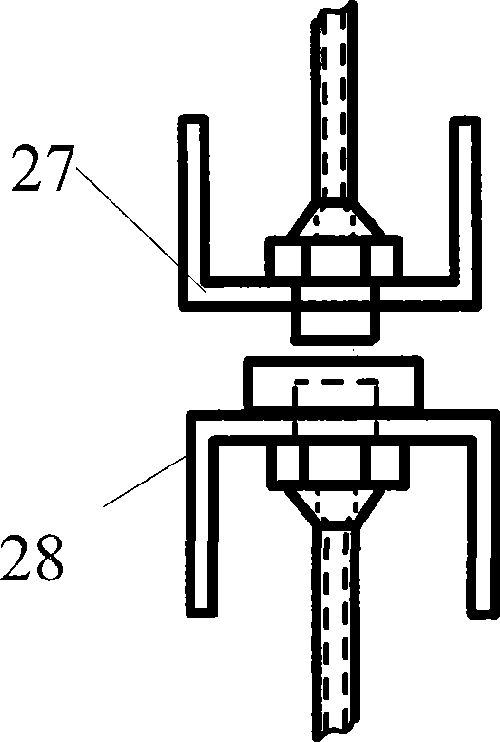

[0023] refer to figure 1 , a high-precision gas leakage detection device, including a standard container 14, a container to be tested, and a gas source 1, the gas source 1 is connected to a gas source processing device 2, and the outlet of the gas source processing device is provided with a detection decompression Valve 3 and inflation decompression valve 20, the detection decompression valve 3 is connected to the main joint valve 4, a pressure gauge 27 is externally connected between the two, the main joint valve 4 is connected to the detection pipeline through the detection joint valve 5a, and the The terminal of the detection pipeline is connected to the measured container, and the main joint valve 4 is connected to the standard container pipeline through the standard joint valve 5b, and the terminal of this pipeline is connected to the standard container 14. A joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com