Combination elevator pulley and method for manufacturing same

A manufacturing method and combined technology, which can be used in portable lifting devices, belts/chains/gears, elevators, etc., can solve problems such as not found, and achieve the effects of energy saving, environmental protection, friction improvement, and easy combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

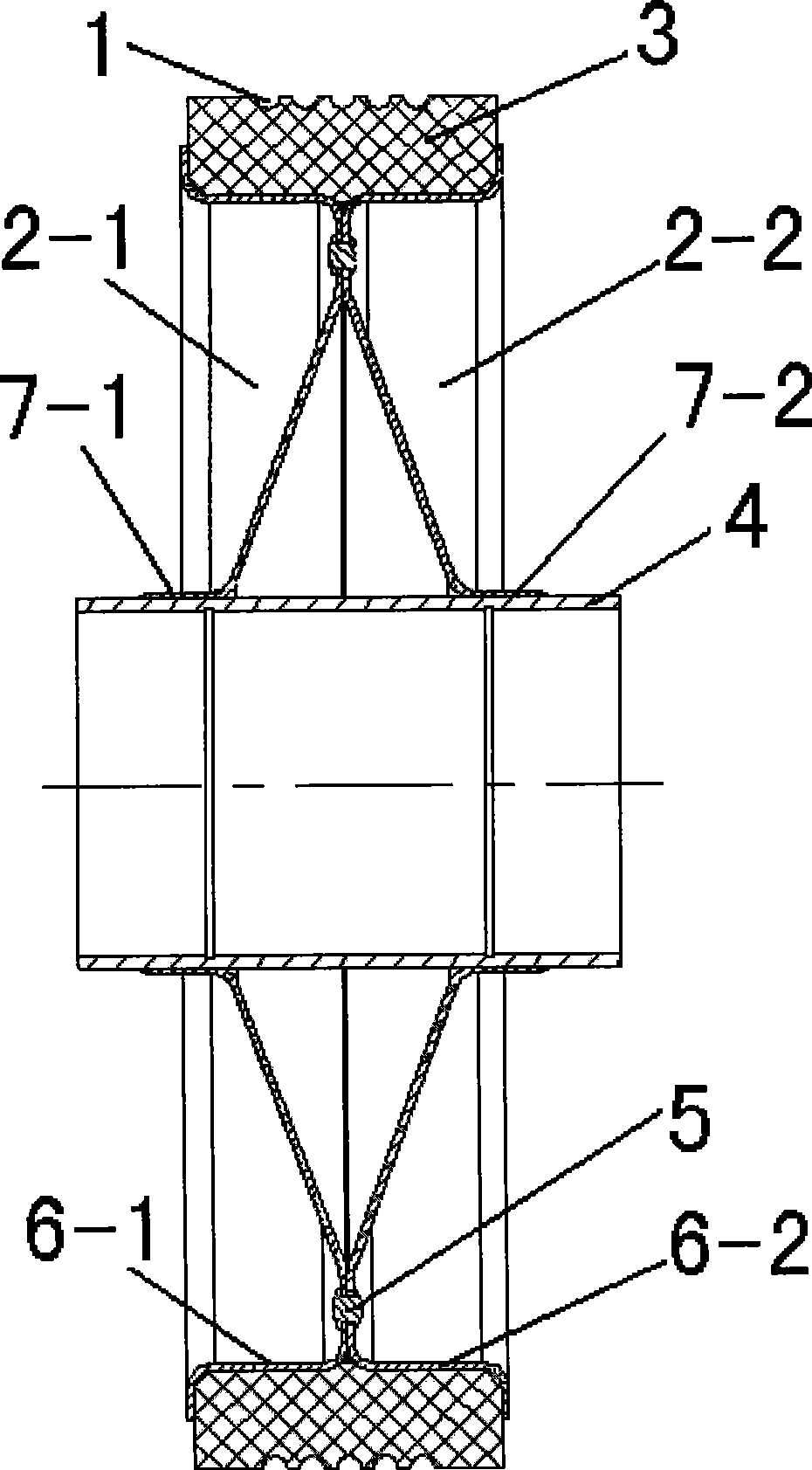

[0017] attached figure 1 It is a structural schematic diagram of the combined elevator pulley of the present invention, which is the best implementation mode of the present invention.

[0018] According to attached figure 1 It can be clearly seen that the combined elevator pulley structure of the present invention includes two metal half-hubs 2-1 and 2-2, a wheel rim 3, and a bearing sleeve 4 that are identical in shape and specification and fit tightly together. Composition, the tightly fitted half-hubs 2-1 and 2-2 are respectively flat / straight towards the outside of the bell mouth, wherein,

[0019] The middle sections of the half-hubs 2-1 and 2-2 are horn-shaped shells or conical shells,

[0020] The middle of the trumpet-shaped housing or the conical housing of the described half-hub 2-1 and 2-2 is flanged outwards resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com