Production method and equipment of drench film coated by PLA biological decomposition material

A technology of biodegradation and PLA, applied in the direction of drying solid materials, heating to dry solid materials, layered products, etc., can solve the problems of heavy burden on consumers, inability to reduce costs, inability to generalize, etc., and achieve easy and fast lamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

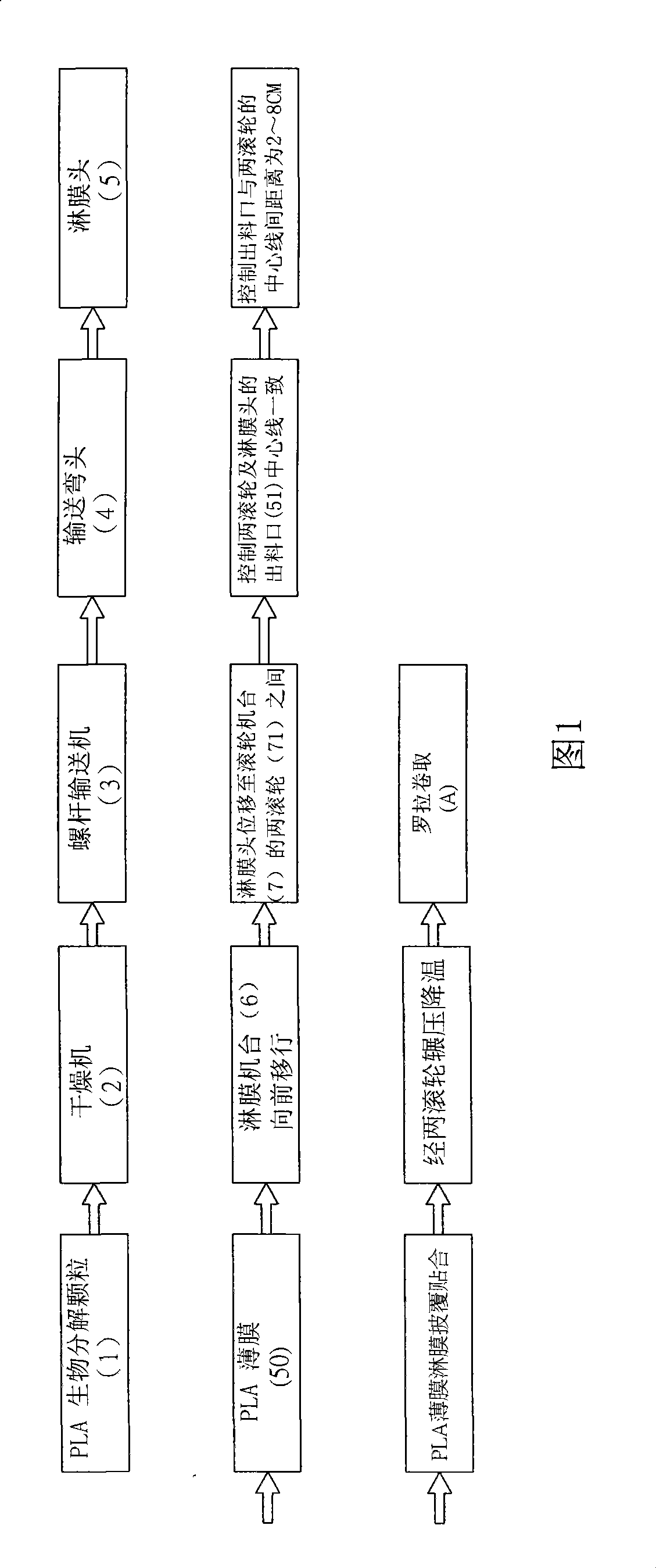

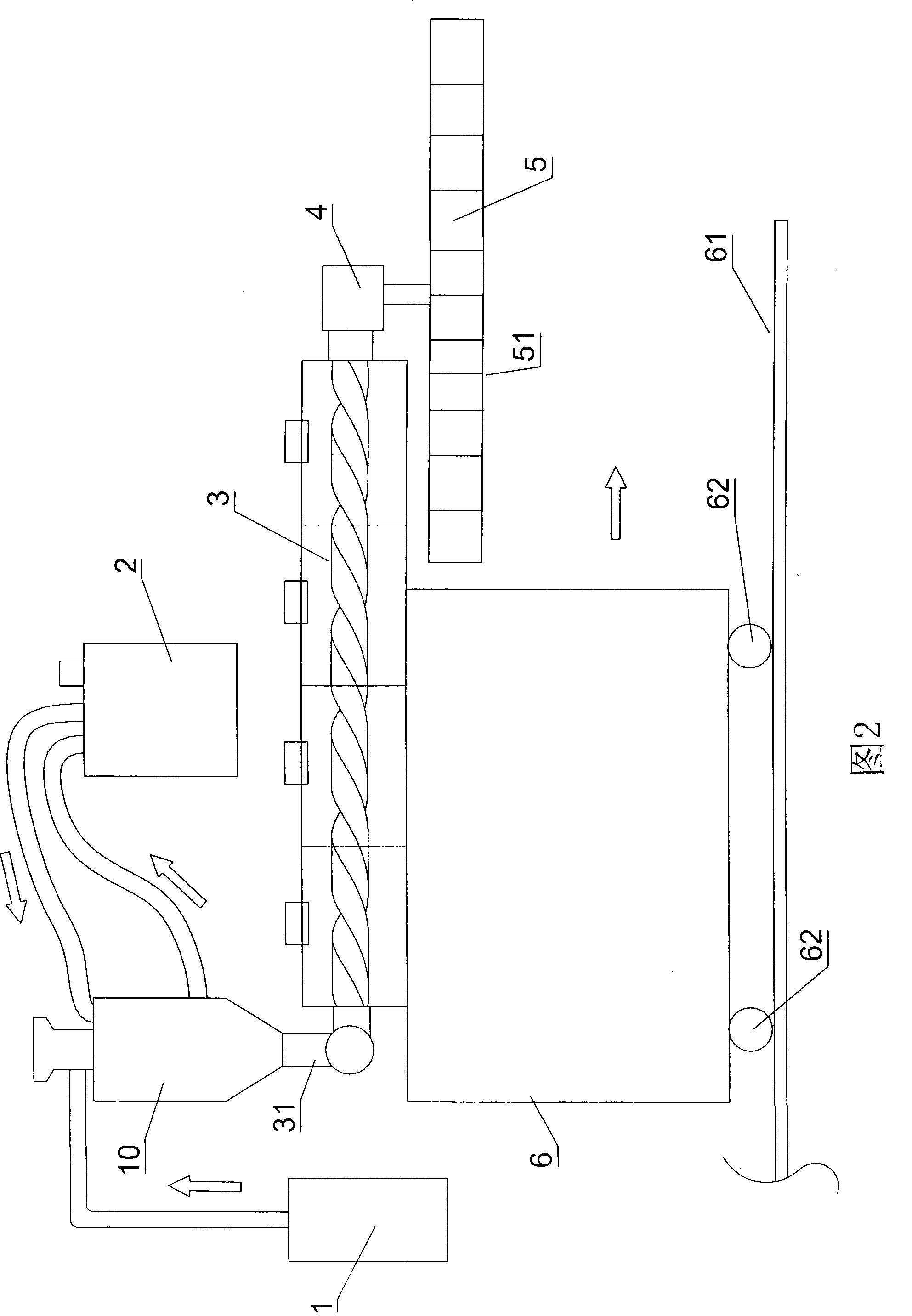

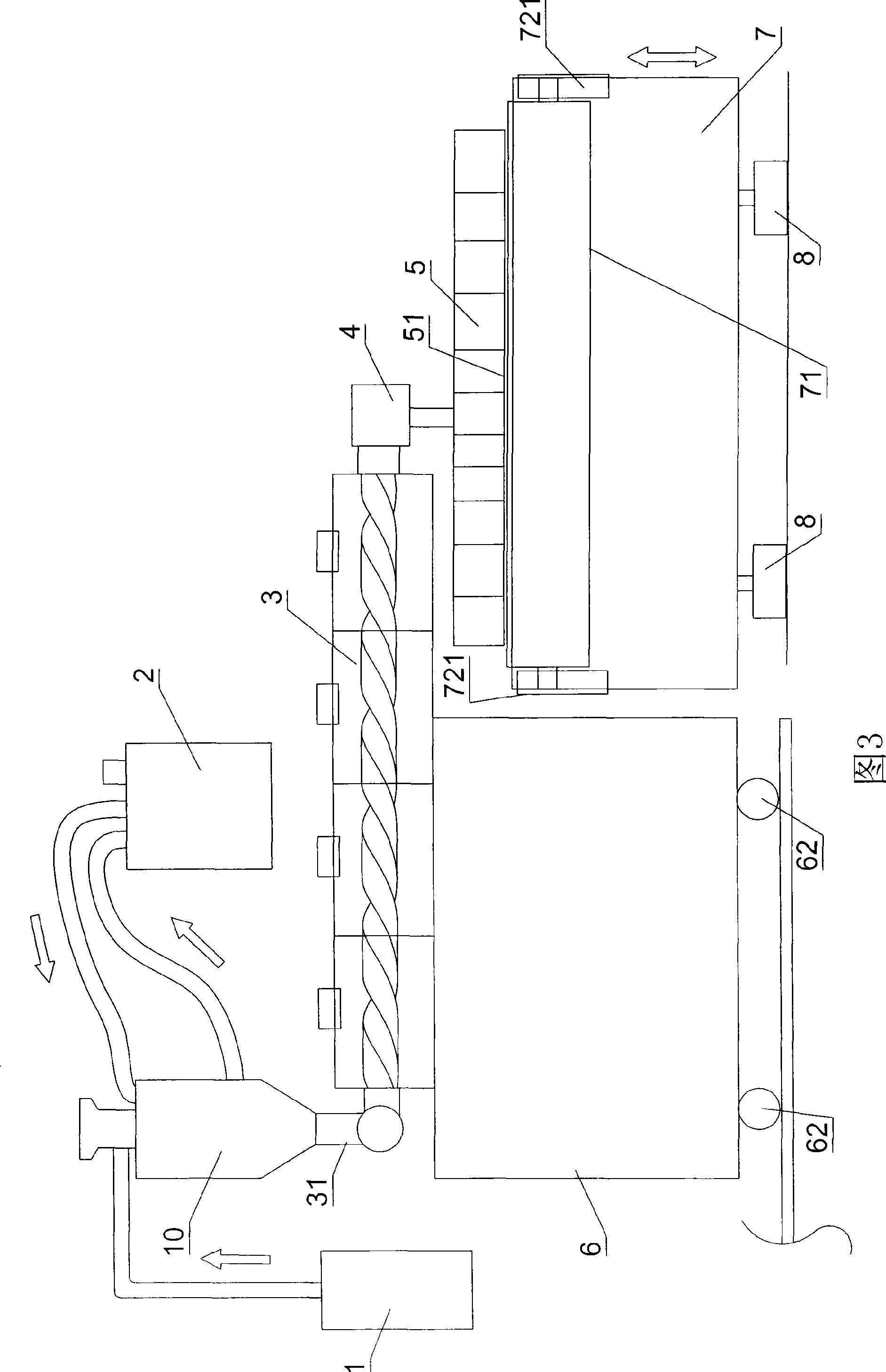

[0031] See also Fig. 1, Fig. 2, shown in Fig. 4, be to apply PLA biodegradable particle 1 to enter drying barrel 10, send hot air into described drying barrel 10 by dryer 2, and the moisture content of PLA biodegradable particle 1 After being recovered to the dryer 2 and treated to a certain standard humidity, the PLA biodegradable particles are heated and melted by the screw conveyor 3 on the one hand, and enter the coating head 5 through the feeding elbow 4 on the other hand, and a PLA film 50 is extruded (as shown in the figure) 2), then advance the laminating machine 6 to a certain position (as shown in Figure 3), and make the laminating head 5 between the two rollers 71 of the roller machine 7, and then control it by a horizontal hydraulic cylinder 72 The shaft is provided with the fixed sliding seat 721 of the two rollers 71 to fine-tune the left and right displacements, so that the coating head 5 is located at the centerline position between the two rollers 71, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com