Protection device for laser welding head

A laser welding head and protection device technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of focusing mirror pollution, achieve the effects of avoiding pollution, protecting weld seams, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

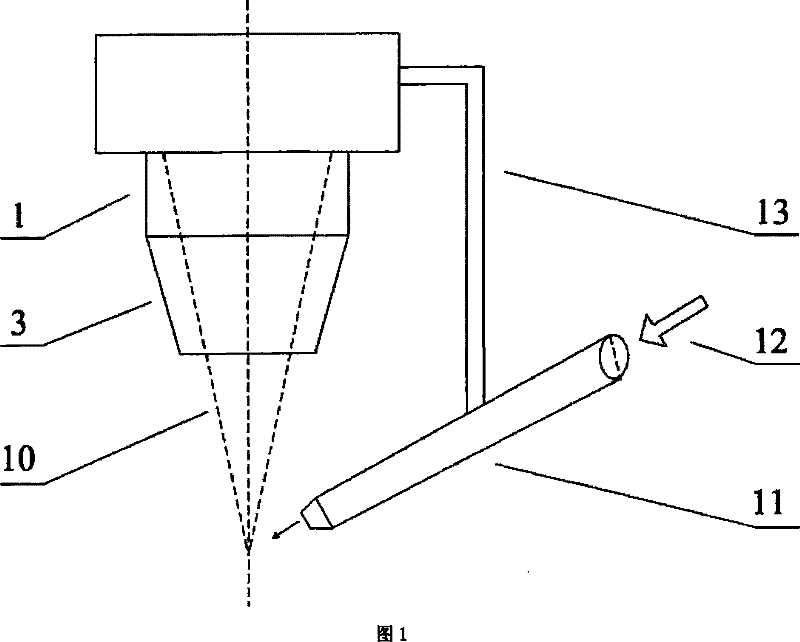

[0039] refer to figure 1 , make a protective device of the present invention, which is composed of a body 14 and a side-blowing protective gas nozzle; the side-blowing protector nozzle 11 is fixed on the protective device body 14 through a fixed bracket 13, such as a movable joint.

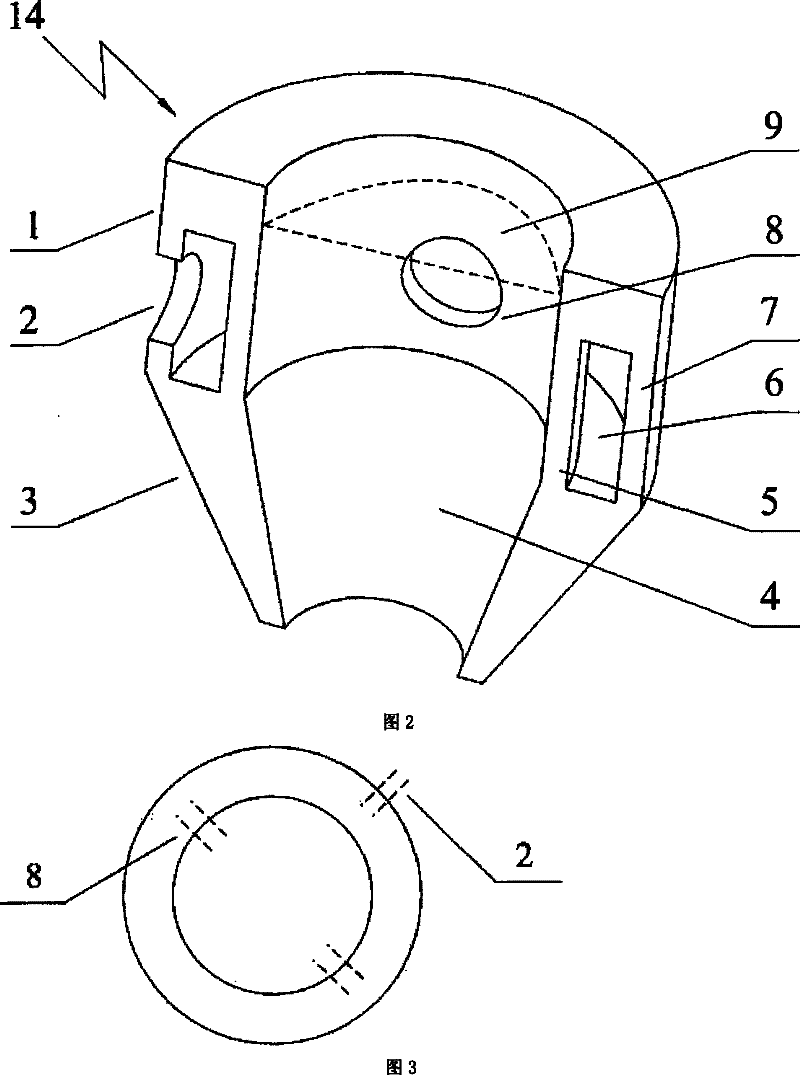

[0040] refer to figure 2 , 3 , the body of the protective device is made of aluminum cylindrical tube 1 and conical tube 3 are integrated into one. The external diameter that makes cylindrical tube 1 is for example 70, 90 or 100mm, and internal diameter is for example 50, 55 or 60mm; Wherein, cylindrical tube 1 top external diameter is 80mm, and internal diameter is 50mm; Cylindrical tube 1 bottom outer ring 7 The outer diameter of the cylinder is 80mm, and the inner diameter is 75mm; the outer diameter of the lower inner ring 5 of the cylindrical tube 1 is 55mm, and the inner diameter is 50mm. The inner diameter of the upper opening of the conical cylinder 3 is 50 mm, the inner diameter of th...

Embodiment 2

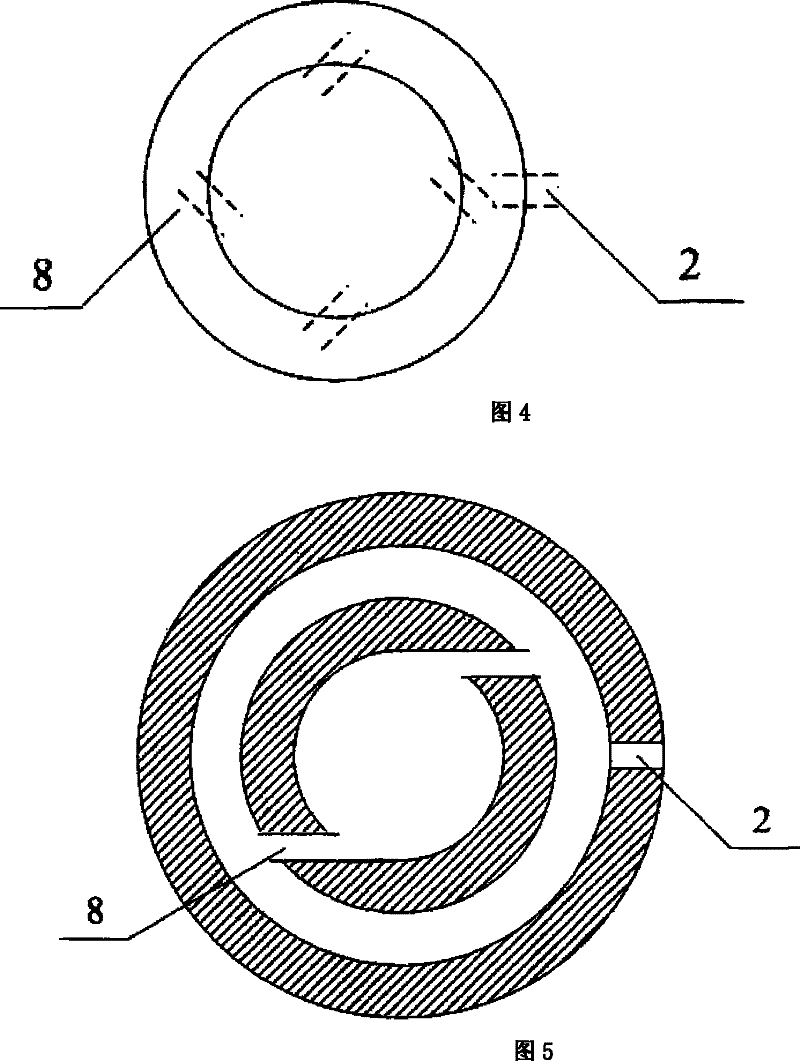

[0043] Add 4 air inlets 8 in the shielding gas on the device made by embodiment 1, as Figure 4 shown. Wherein the setting of shielding gas inlet 8 forms a certain angle according to the axis of the air inlet in the shielding gas and the tangent line of the wall surface of circular tube inner ring 5, the angle range is 0°-90° (parallel-vertical), the taper of conical tube 3 It is 1:6.

Embodiment 3

[0045] Open 2 air inlets 8 in the shielding gas on the device made by embodiment 1, as Figure 5 shown. Wherein the air inlet 8 in the shielding gas is set according to the parallel horizontal opening of the shielding gas along the tangent line to the outer surface of the cylinder inflatable, and the taper of the conical tube 3 is 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com