Processing technique of Qihong Huang tea

A processing technology, the technology of imperial tea, applied in the field of processing technology of Qihonghuang tea, can solve the problems of reducing product quality, dull aroma, and excessive tea dust, and achieve the effects of improving grading accuracy, promoting degradation, and improving shape uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

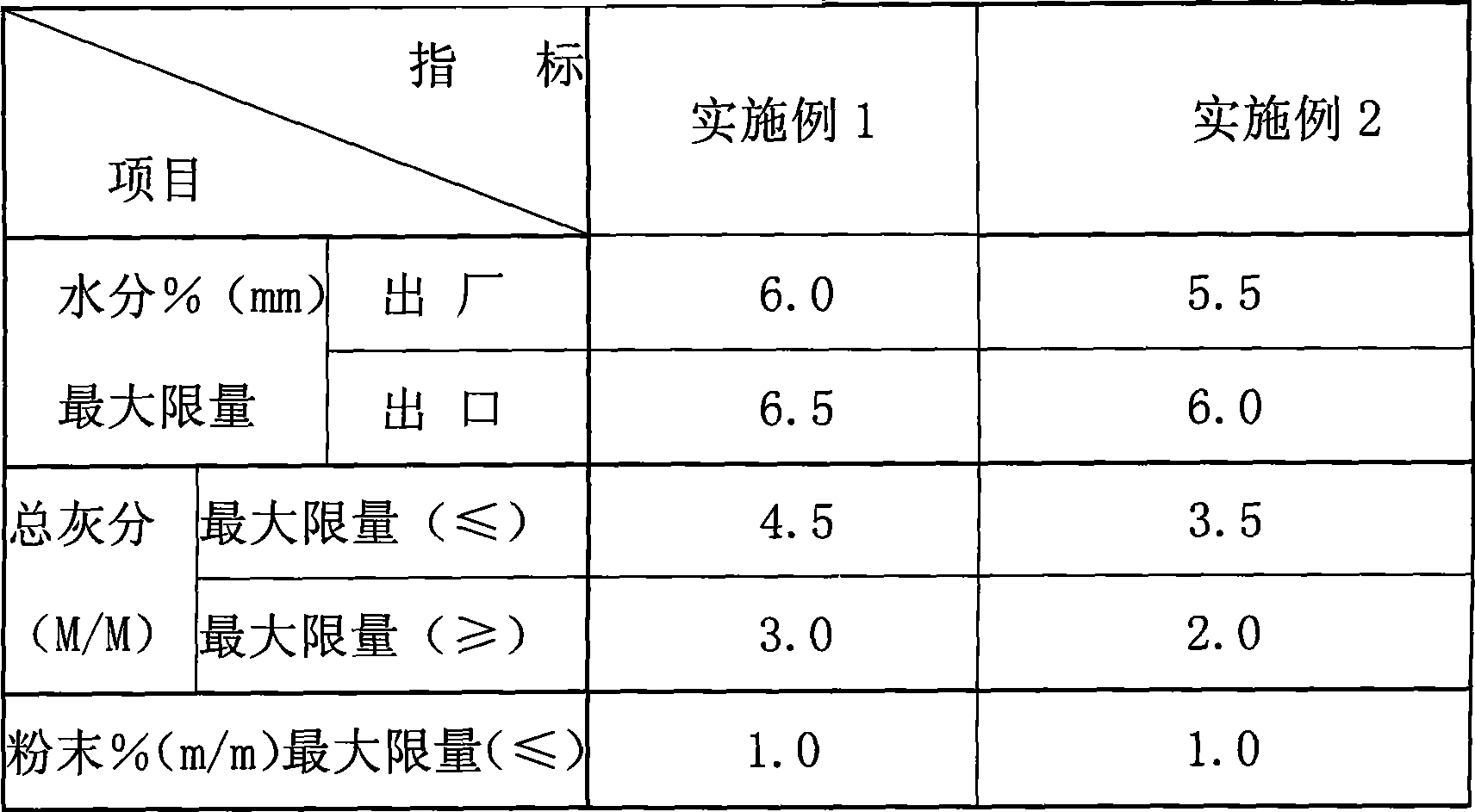

Examples

Embodiment 1

[0027] 1. Picking process:

[0028] The fresh leaves are picked from the natural coriander leaf tea tree at an altitude of 800m above sea level. The picking standard is one bud (bud head) of fresh leaves before Qingming. The isolated fresh leaves picked from the tea tree should be sent to the primary factory in time to keep the fresh leaves The freshness should not be compressed during transportation and storage.

[0029] 2. Sorting process:

[0030] After picking fresh leaves, the sundries in the fresh leaves (tea seeds, flower buds, young fruits, withered leaves, and old leaves in the next year) are manually picked out, and the four aspects of bud leaves, tenderness, uniformity, clarity, and freshness Carry out classification, pick out a bud (bud head).

[0031] 3. Sorting and cooling process:

[0032] The Qimen mountain area is high and rainy, and there are few sunny days in spring. When the fresh leaves enter the factory, they are mostly rain leaves and dew leaves. Usua...

Embodiment 2

[0062] 1. Picking process:

[0063] The fresh leaves are picked from the natural coriander leaf tea trees at an altitude of 500m or more. The freshness should not be compressed during transportation and storage.

[0064] 2. Sorting process:

[0065] After picking fresh leaves, the sundries in the fresh leaves (tea seeds, flower buds, young fruits, withered leaves, and old leaves in the next year) are manually picked out, and the four aspects of bud leaves, tenderness, uniformity, clarity, and freshness Carry out classification, pick out a bud (bud head).

[0066] 3. Sorting and cooling process:

[0067] The Qimen mountain area is high and rainy, and there are few sunny days in spring. When the fresh leaves enter the factory, they are mostly rain leaves and dew leaves. Usually, they are first spread and aired on the floor (withering board) outside the withering room for 180-200 minutes, depending on the thickness of the leaves. It is 8-10 cm, and the water on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com