Fender module

A technology of shock absorbers and modules, applied in the direction of vehicle components, upper structure sub-assembly, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

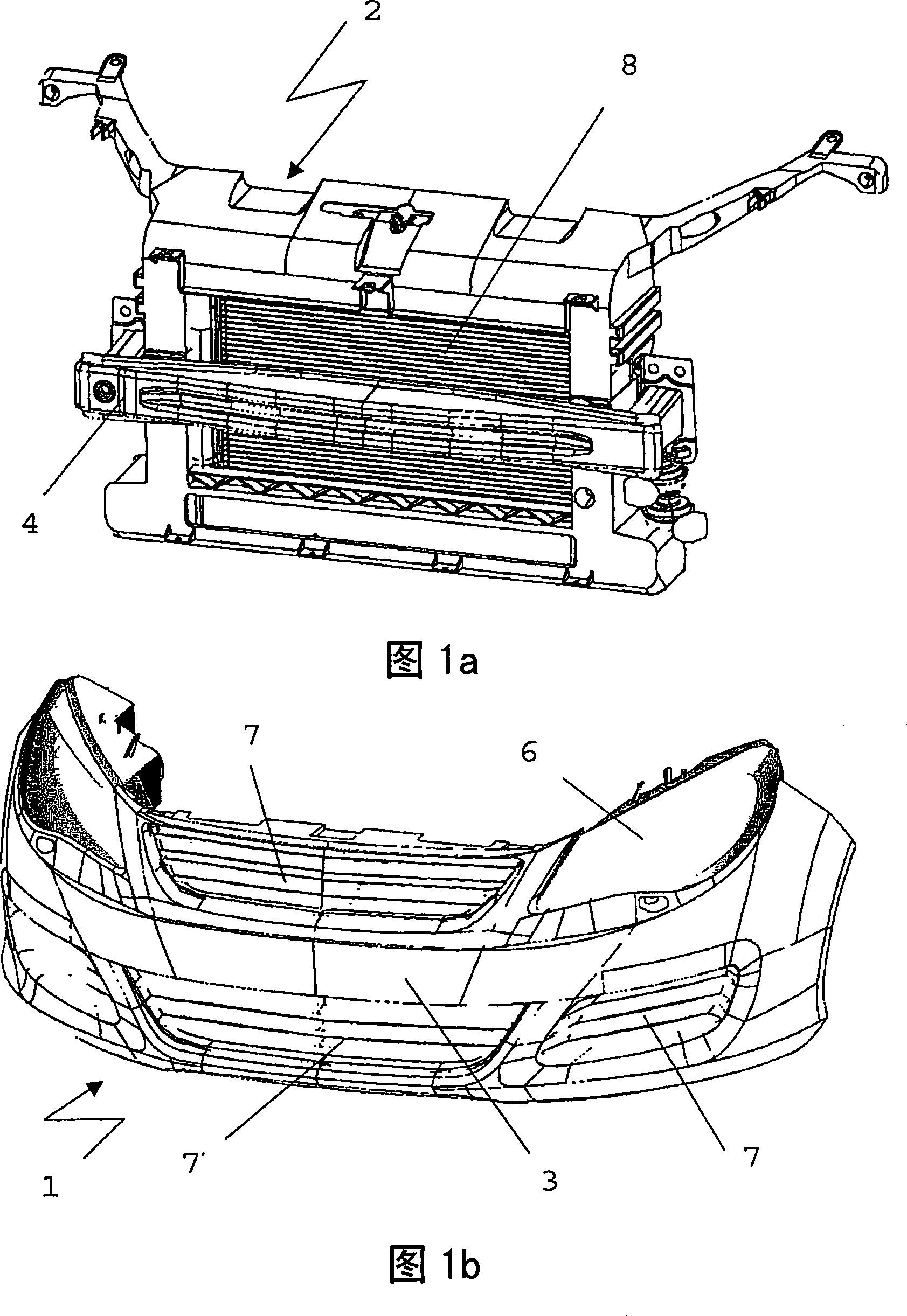

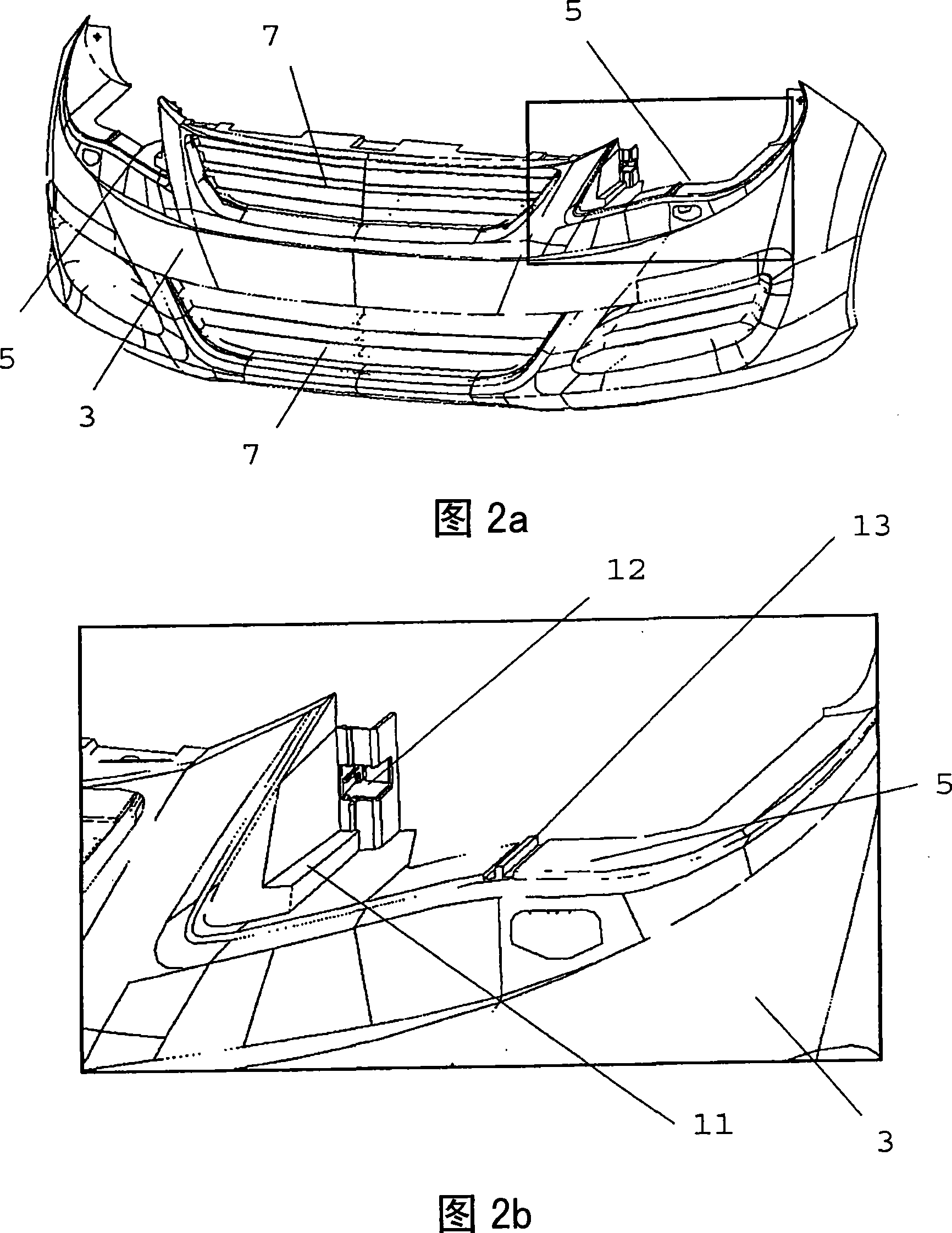

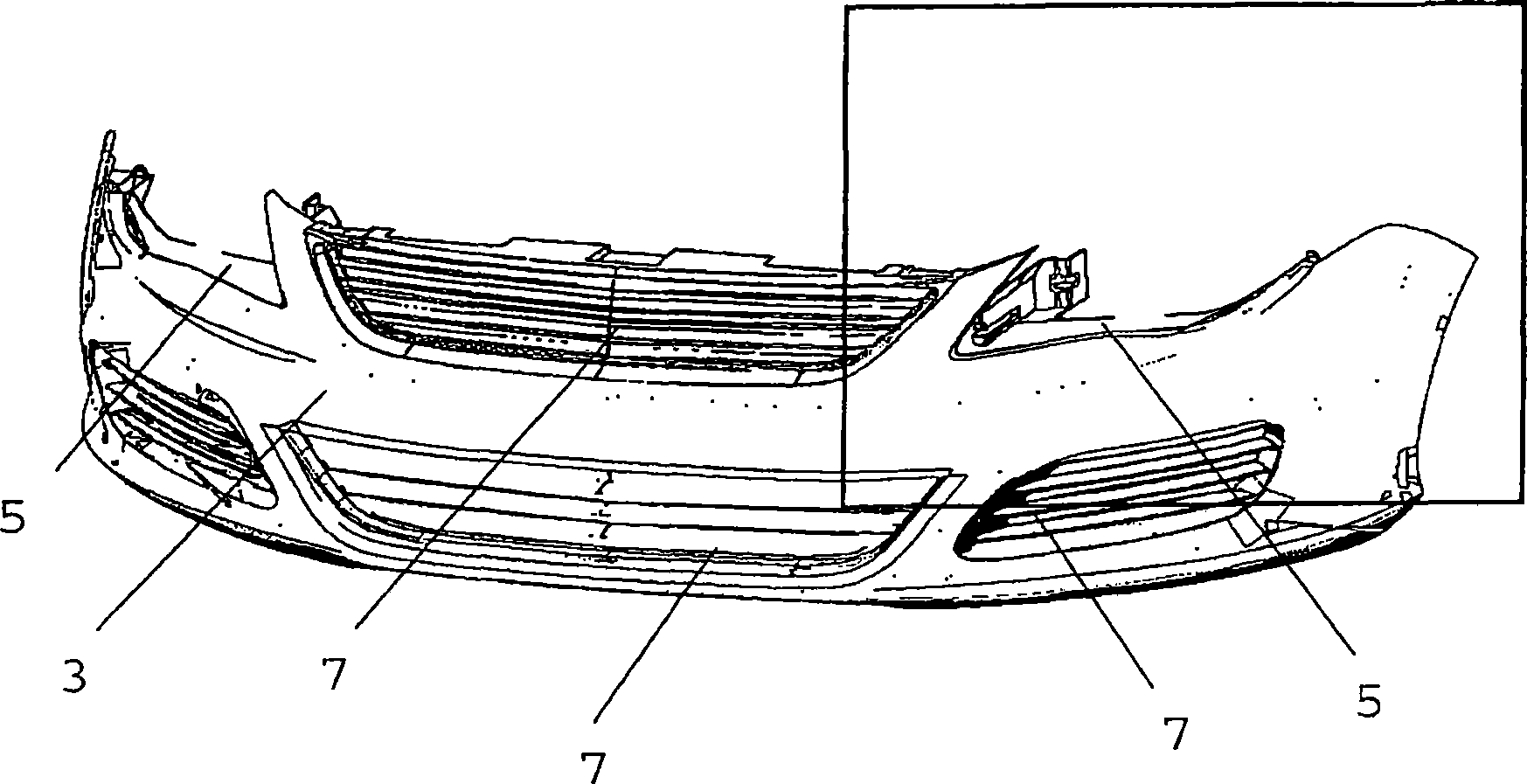

[0030] Figure 1b shows a shock absorber module 1 according to the invention, which essentially consists of a shock absorber housing 3 with an integral support structure 5, said The support structure is covered in this figure by a headlight 6 which is inserted into the support structure 5 with a uniform seam distribution.

[0031] Various cooler fin structures 7 are integrated in the shock absorber housing 3 as additional components. Furthermore, FIG. 1 a shows a separate front end support 2 with a shock absorber bending support 4 and a cooler 8 . In the embodiment shown in FIGS. 1a and 1b, the assembly can be directly combined with the shock absorber module 1 to form a front module and can be connected to one another, for example, by corresponding mounting surfaces, form-fit connections or screw connections. into a structural unit.

[0032] In another embodiment, the assembly consisting of the front end bracket 2, the shock absorber bracket 4 and the cooler 8 is first placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com