Timing chain of engine

An engine and silent technology, applied in the direction of engine components, machines/engines, transmission chains, etc., can solve the problems of no long-life transmission components, large chain transmission noise, easy damage to the gauge belt, etc., so that it is not easy to elongate and break, reduce Vibration noise, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

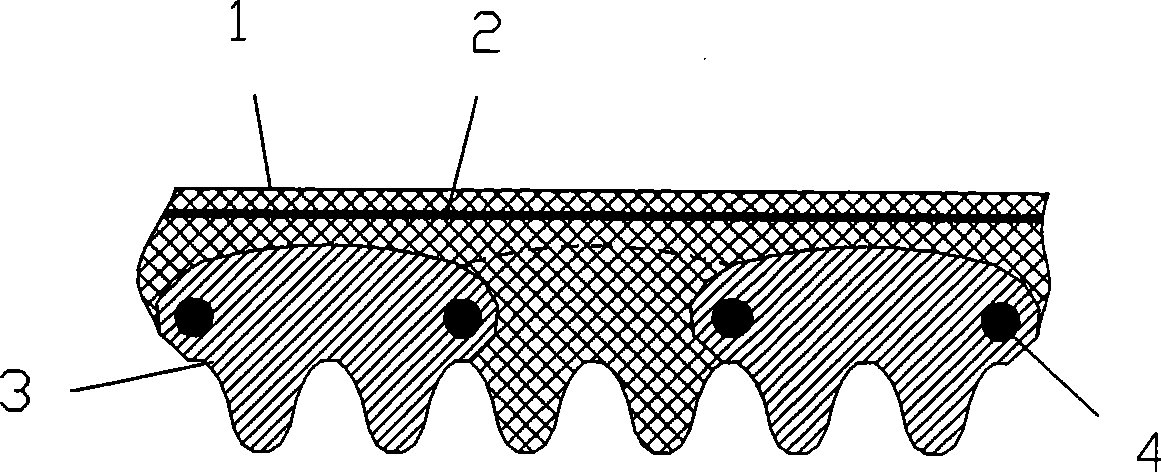

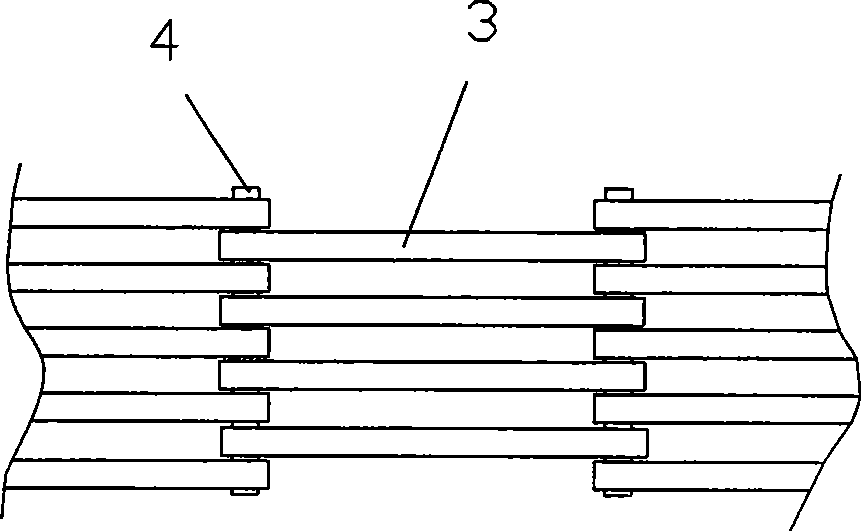

[0011] combine figure 2 and image 3 , the chain part of the embodiment is composed of chain pieces 3 and pins 4 connecting each chain piece 3, and each chain is composed of parallel chain pieces 3, and there are four pieces and five pieces respectively, and the chain pieces between adjacent chains of each section 3 are staggered and embedded, connected in series with pins 4, and the inner side of the chain sheet 3 is shaped on an involute sprocket, and this structure is the same as the existing timing chain.

[0012] combine figure 1 and figure 2 , the chain is embedded in the rubber belt 1, and is made as a whole with the rubber belt 1, the tooth surface of the sprocket is flat with the inner tooth surface of the rubber belt 1, and the cord 2 is embedded in the outer position of the chain in the rubber belt 1.

[0013] ·The rubber belt is made of NBR or Viton, and the chain piece 3 is made of iron plate.

[0014] After the chain is embedded in the rubber belt, rubber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com