Recycled concrete shear wall with cross reinforcement conversion layer and its production method

A technology of recycled concrete and shear walls, applied to walls, building materials, building components, etc., can solve problems such as deterioration of the ecological environment and difficulties in the disposal of waste concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

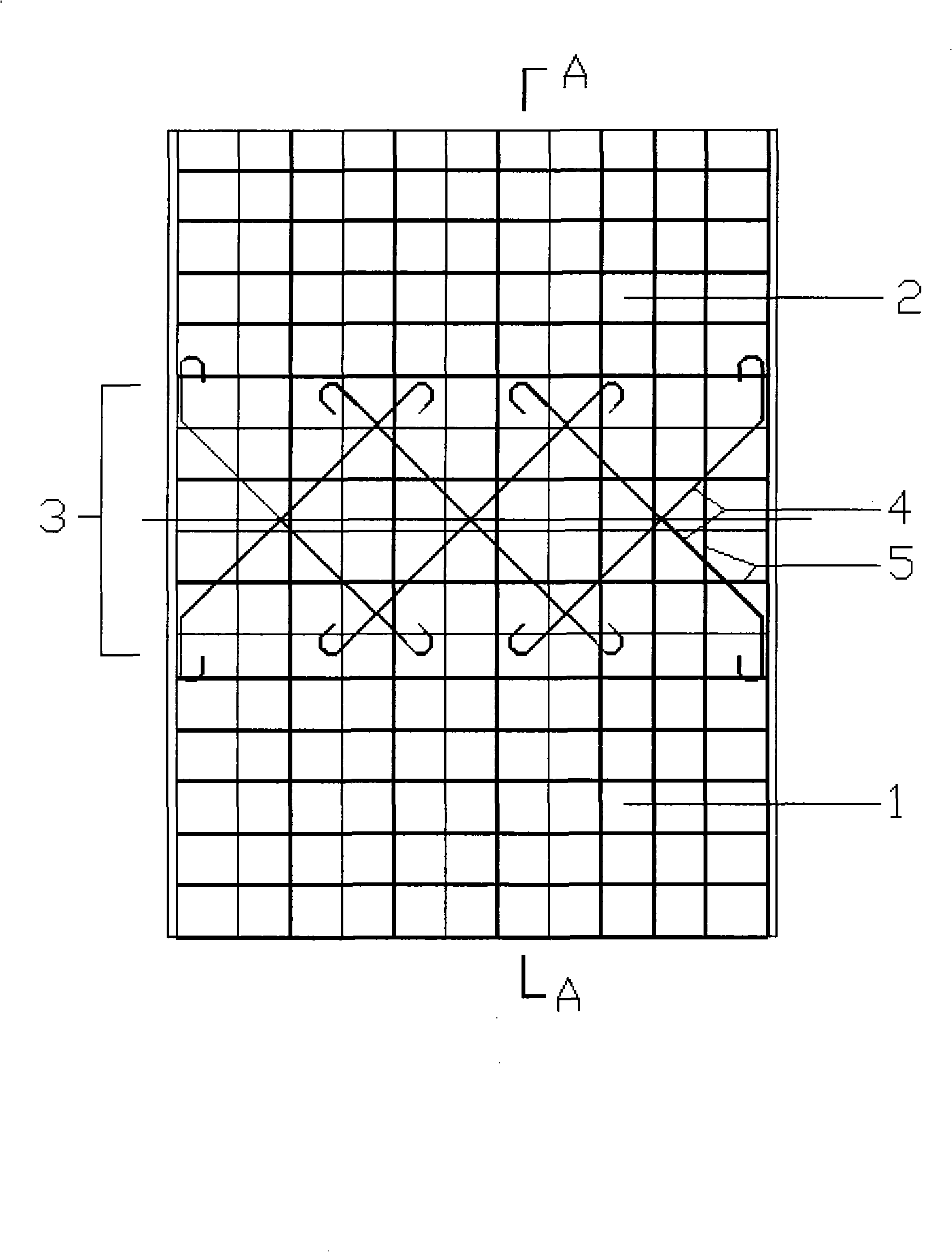

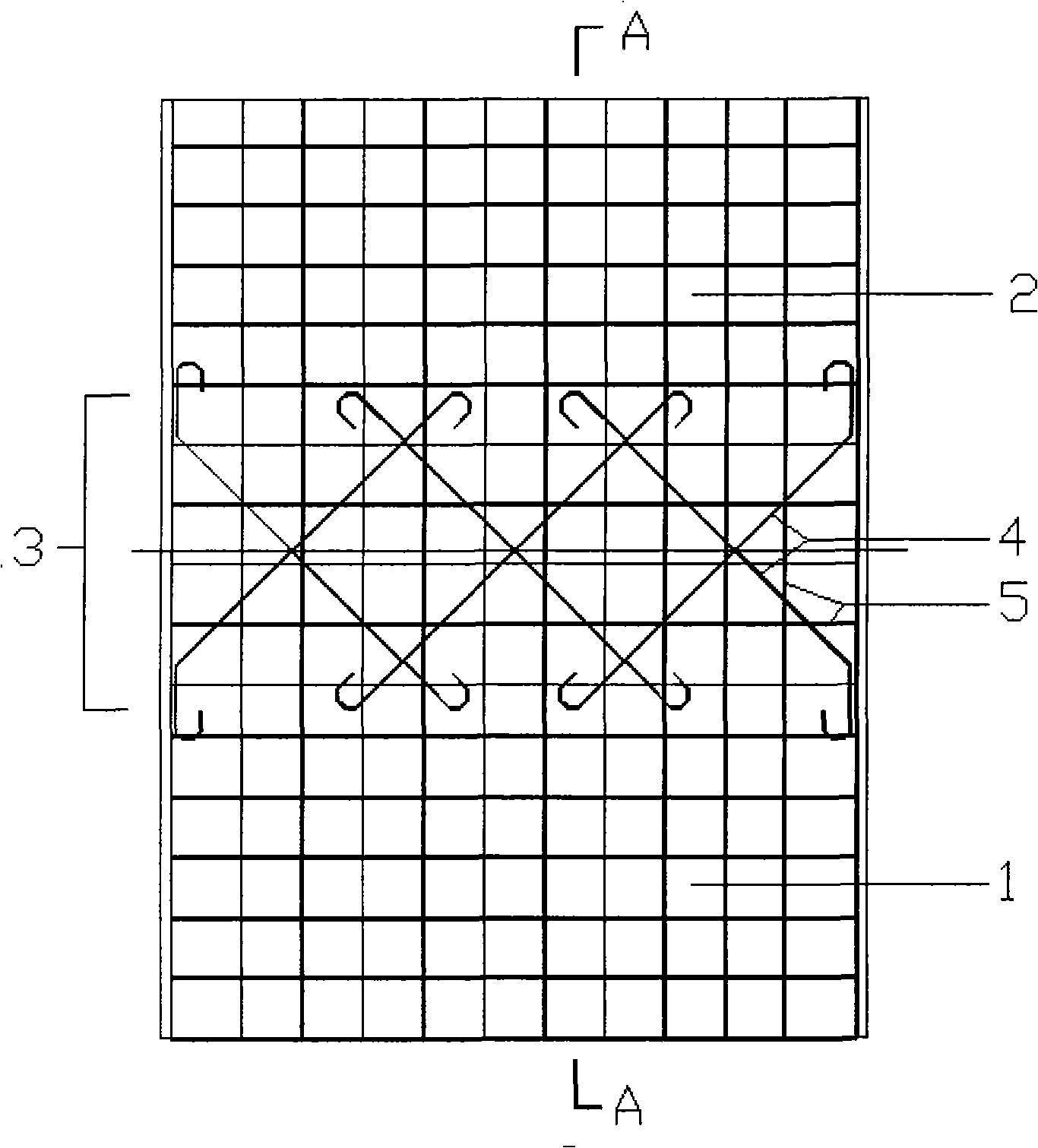

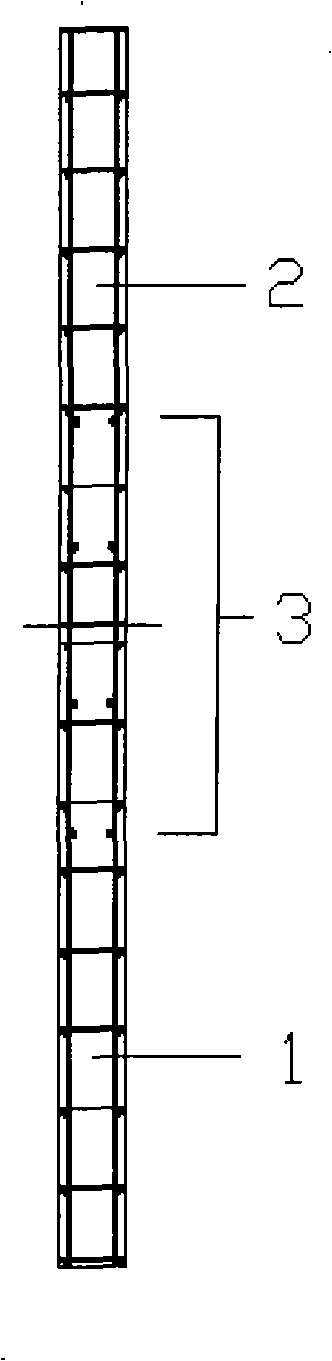

[0018] The structural form of a recycled concrete shear wall with a cross-reinforced transfer layer is shown in Figure 1-2. The lower part is made of ordinary concrete 1, and the upper part is made of recycled concrete 2, and two steel meshes 5 are set inside the transfer layer 3 in the middle of the shear wall. X-shaped steel oblique support 4, whose upper end extends into the upper shear wall and its length is greater than or equal to 2 times the wall thickness, and is bound to the steel mesh 5 in the shear wall; its lower end extends into the lower shear wall and its length is greater than It is equal to 2 times the wall thickness and is bound to the steel mesh 5 in the shear wall. Other structural reinforcements include: the two steel reinforcement meshes 5 of the shear wall are connected by tie bars with a spacing less than or equal to 600 mm.

[0019] The production steps are as follows:

[0020] 1) Configure the steel bars of the frame columns on both sides of the shear wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com