Zirconium based amorphous alloy and manufacture method thereof

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of zirconium-based amorphous alloy and its preparation, can solve the problems of poor plasticity and small size, achieve good plasticity, improve applicability, and avoid sudden failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the zirconium-based amorphous alloy provided by the invention comprises the steps of vacuum melting and cooling the amorphous alloy raw material under the protection of an inert gas.

[0018] The preparation raw materials of the zirconium-based amorphous alloy provided by the present invention include Zr, Ti, Cu, Ni, Fe, and Be, wherein the preparation raw materials also include Sn and optionally contained ETM and LTM.

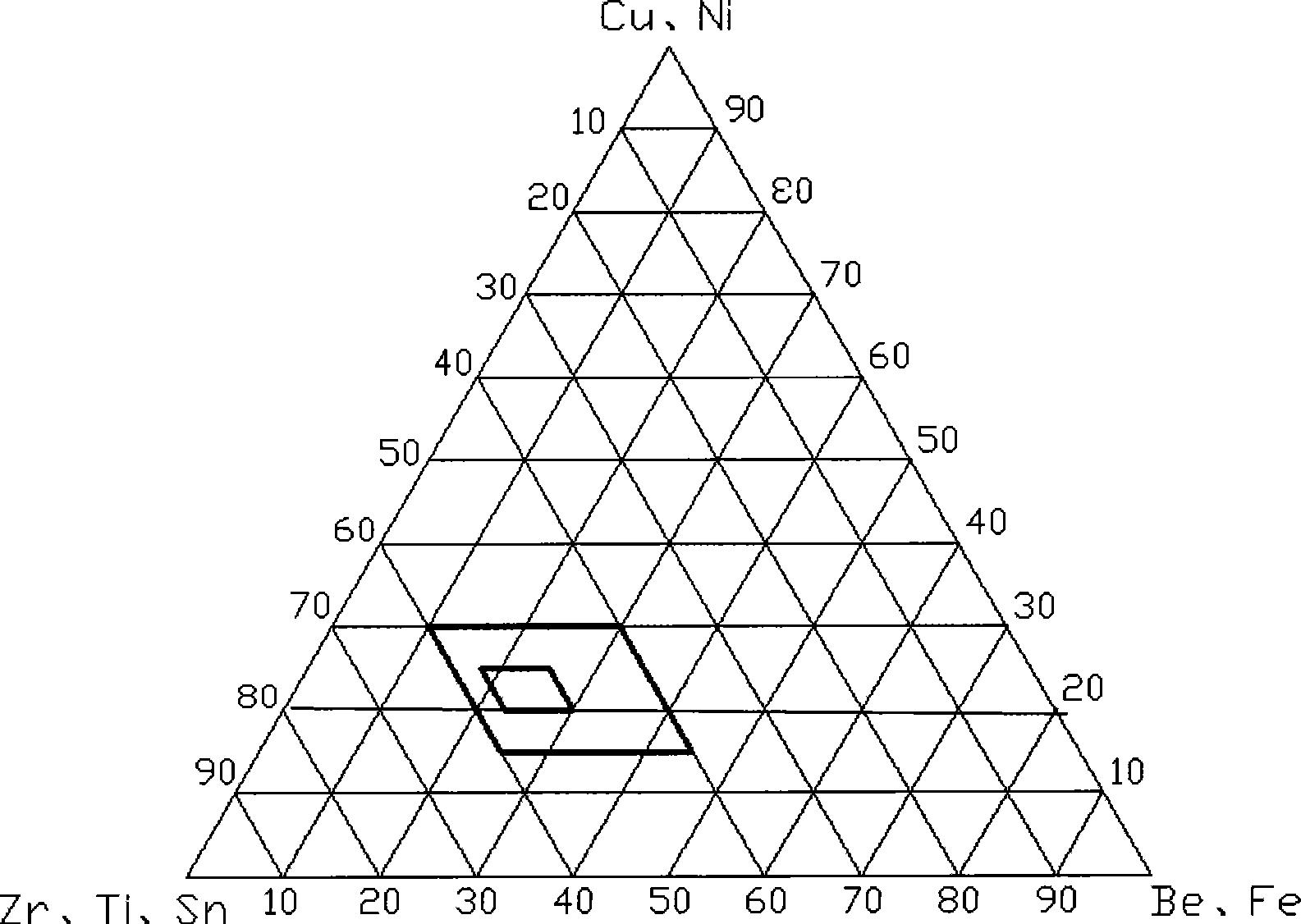

[0019] The addition amount of various elements will make the alloy composition of making be the composition represented by the following general formula: (Zr x Ti y sn z ) a ETM b (Cu m Ni n ) c Fe d LTM e be f , where a, b, c, d, e and f are mole percentages, a+b+c+d+e+f=100, and 30≤a≤75, 0≤b≤15, 10≤c≤35 , 0.1≤d≤15, 0≤e≤15, 0.1≤f≤35; x, y and z are atomic ratios, x+y+z=1, and 0.6≤x≤0.85, 0.01x≤z≤0.1x ; m and n are atomic ratios, m+n=1, and 0.5≤m≤0.65. Preferably, 40≤a≤60, 0≤b≤10, 15≤c≤25, 0.5≤d≤5, 0≤e≤10, 15≤f≤25. ...

Embodiment 1

[0024] This example is used to illustrate the preparation of the zirconium-based amorphous alloy provided by the present invention.

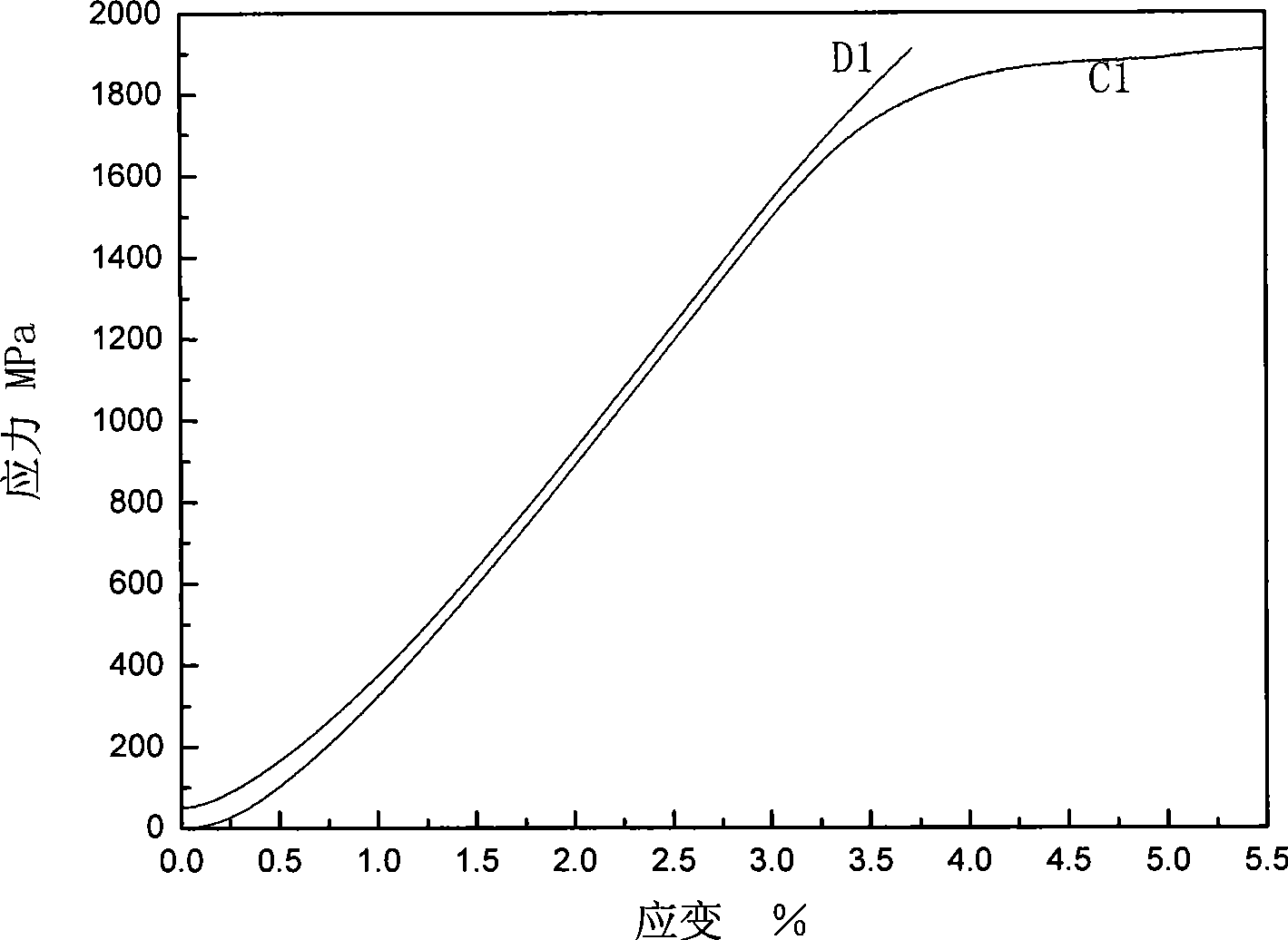

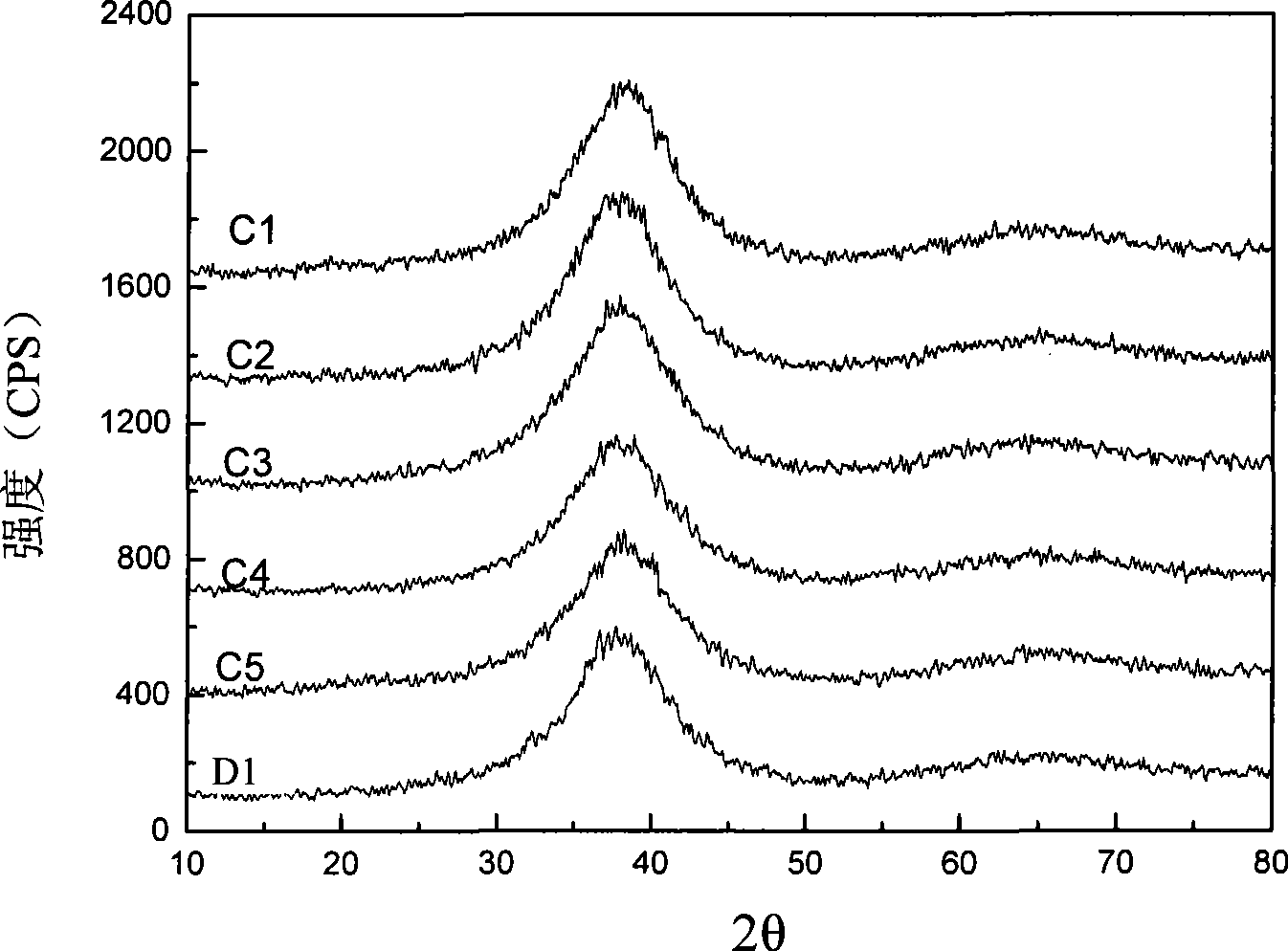

[0025] Raw materials Zr, Ti, Sn, Cu, Ni, Fe, Be total 25g according to the following ratio: (Zr 0.74 Ti 0.25 sn 0.01 ) 55.34 (Cu 0.56 Ni 0.44 ) 20.65 Fe 1.96 be 22.05 , placed in an electric arc melting furnace (Shenyang Scientific Instrument Manufacturing Co., Ltd.) to evacuate to 5Pa, melted at 2000°C for 6 minutes under the protection of argon, and cooled to form an ingot after fully stirring. After melting the ingot at 1500°C by means of arc heating, it was cast in a copper mold with a cooling rate of 10 2 k / s, the zirconium-based amorphous alloy sample C1 was prepared.

Embodiment 2

[0027] This example is used to illustrate the preparation method of the zirconium-based amorphous alloy provided by the present invention.

[0028] According to the description of the inventive method, a total of 200kg of raw materials Zr, Ti, Sn, Cu, Ni, Fe, Be is according to (Zr 0.74 Ti 0.25 sn 0.01 ) 55.34 (Cu 0.56 Ni 0.44 ) 20.65 Fe 1.96 be 22.05 The ratio is placed in an induction melting furnace (Zhongbei Technology) to evacuate to 5Pa, melted at 1800°C for 10 minutes under the protection of argon, and then cooled to form an ingot after fully stirring. After the ingot was melted at 1200°C by means of resistance heating, the cooling rate was 10 by die casting. 4 k / s, the zirconium-based amorphous alloy sample C2 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com