Forming method of hot rolling device and double-sided microstructure optical membrane

A technology of optical film and hot rolling, which can be applied to applications, household appliances, flat products, etc., and can solve the problem of uneven brightness of liquid crystal panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

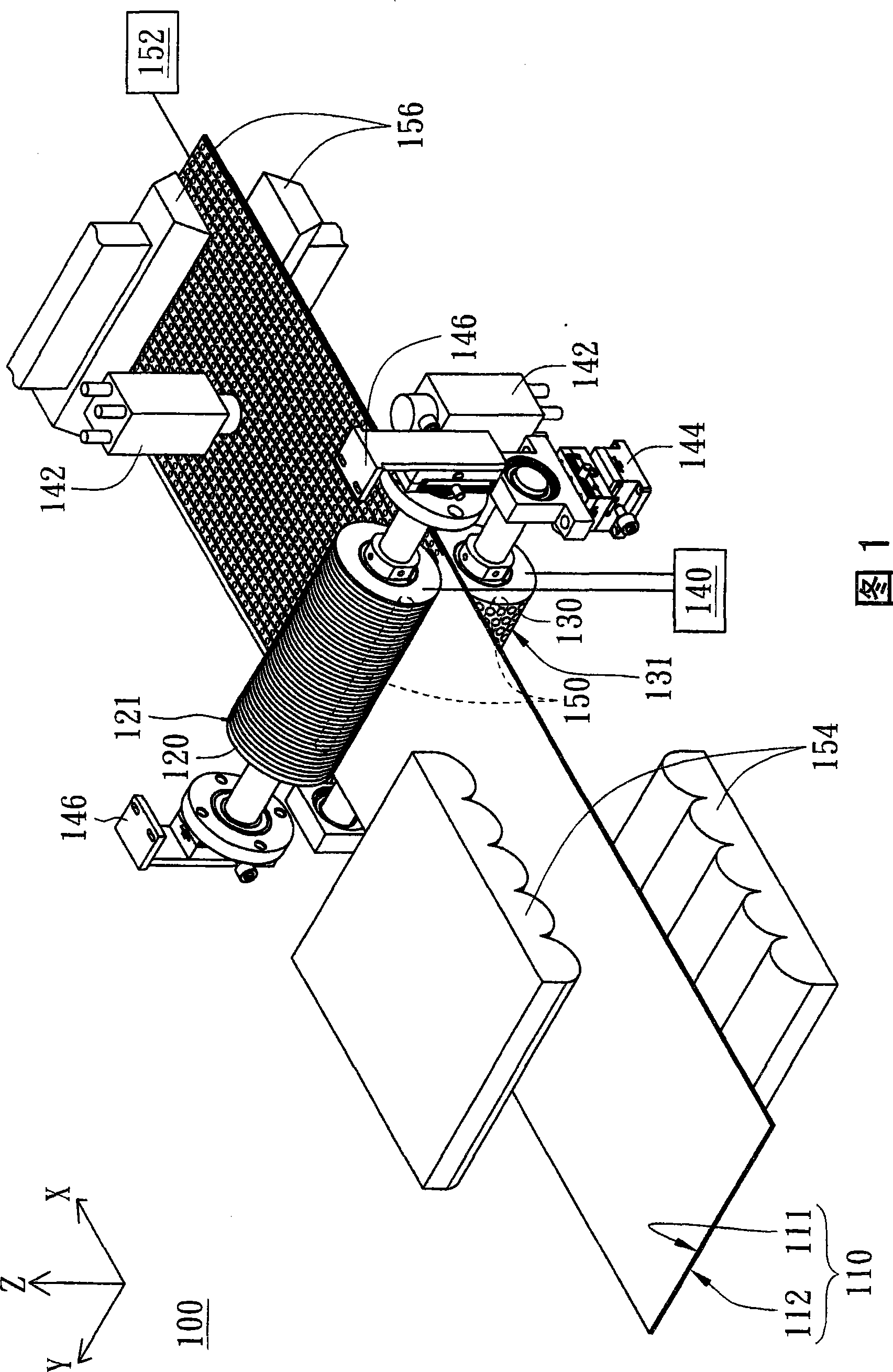

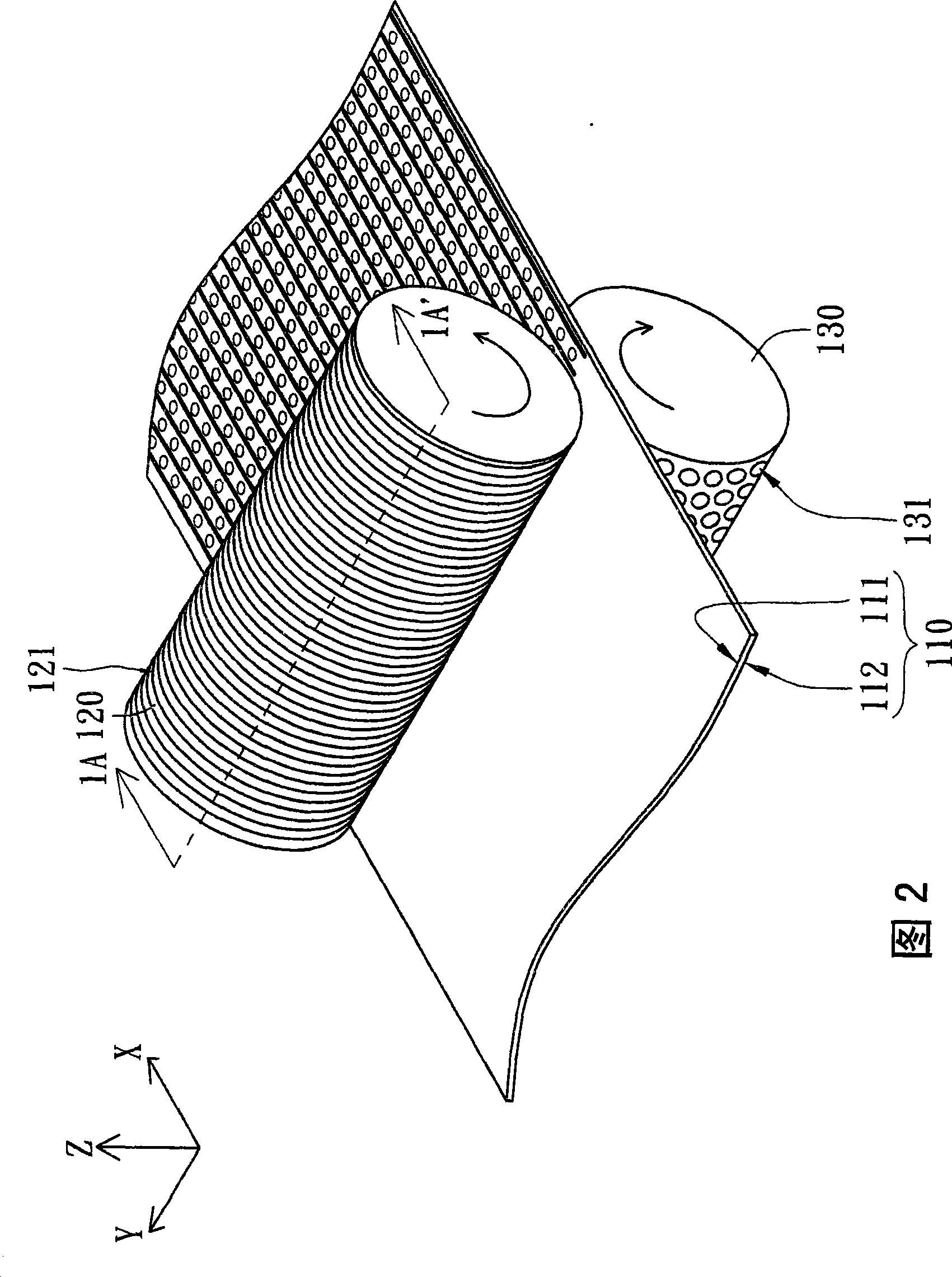

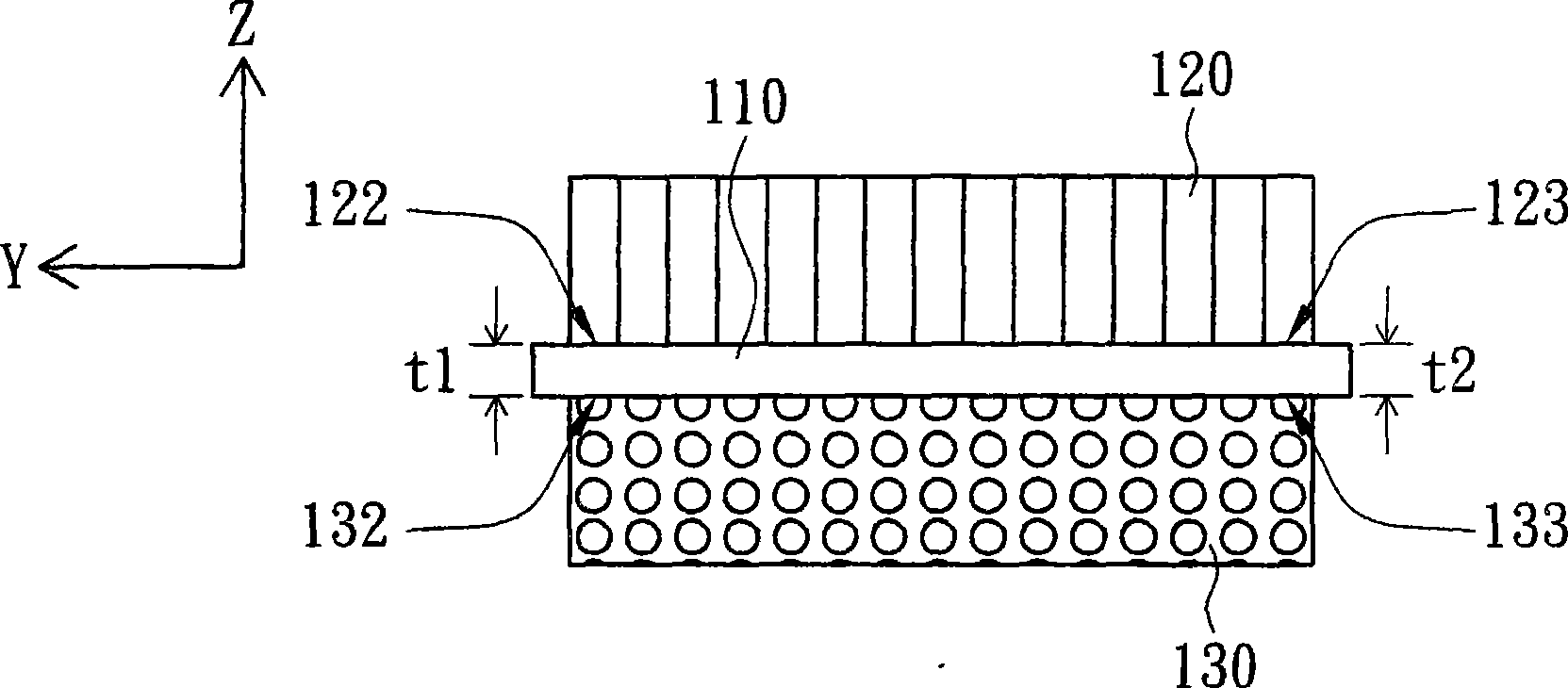

[0061] Please refer to FIG. 1 and FIG. 2 at the same time. FIG. 1 shows a schematic diagram of a thermal rolling device 100 according to a preferred embodiment of the present invention. FIG. 2 shows the first roller 120, the second roller 130 and the optical An enlarged view of diaphragm 110 . For clarity, FIGS. 1 and 2 draw the double-sided microstructures on the optical film 110 with solid lines. As shown in FIG. 1 , the thermal rolling device 100 is used to form double-sided microstructures on a first surface 111 and a second surface 112 of an optical film 110 . The hot rolling device 100 includes a first roller 120 , a second roller 130 and a heating unit 140 . The first roller 120 has a first pattern 121 and the second roller 130 has a second pattern 131 . The first pattern 121 and the second pattern 131 are, for example, one-dimensional or two-dimensional optical microstructure patterns. The heating unit 140 is used for heating the first roller 120 and the second roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com