Composite microbial inoculant for corn silage and use method thereo

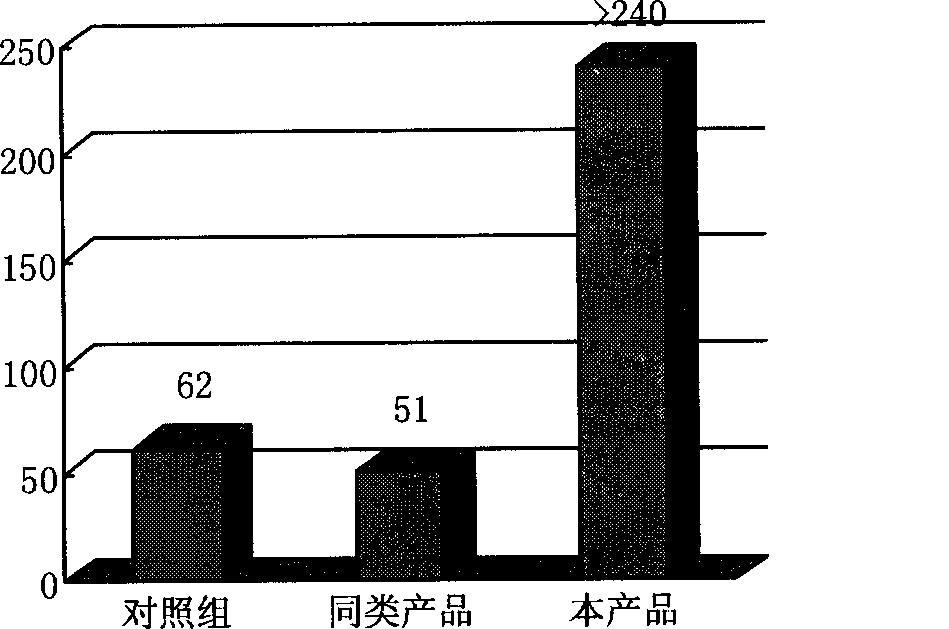

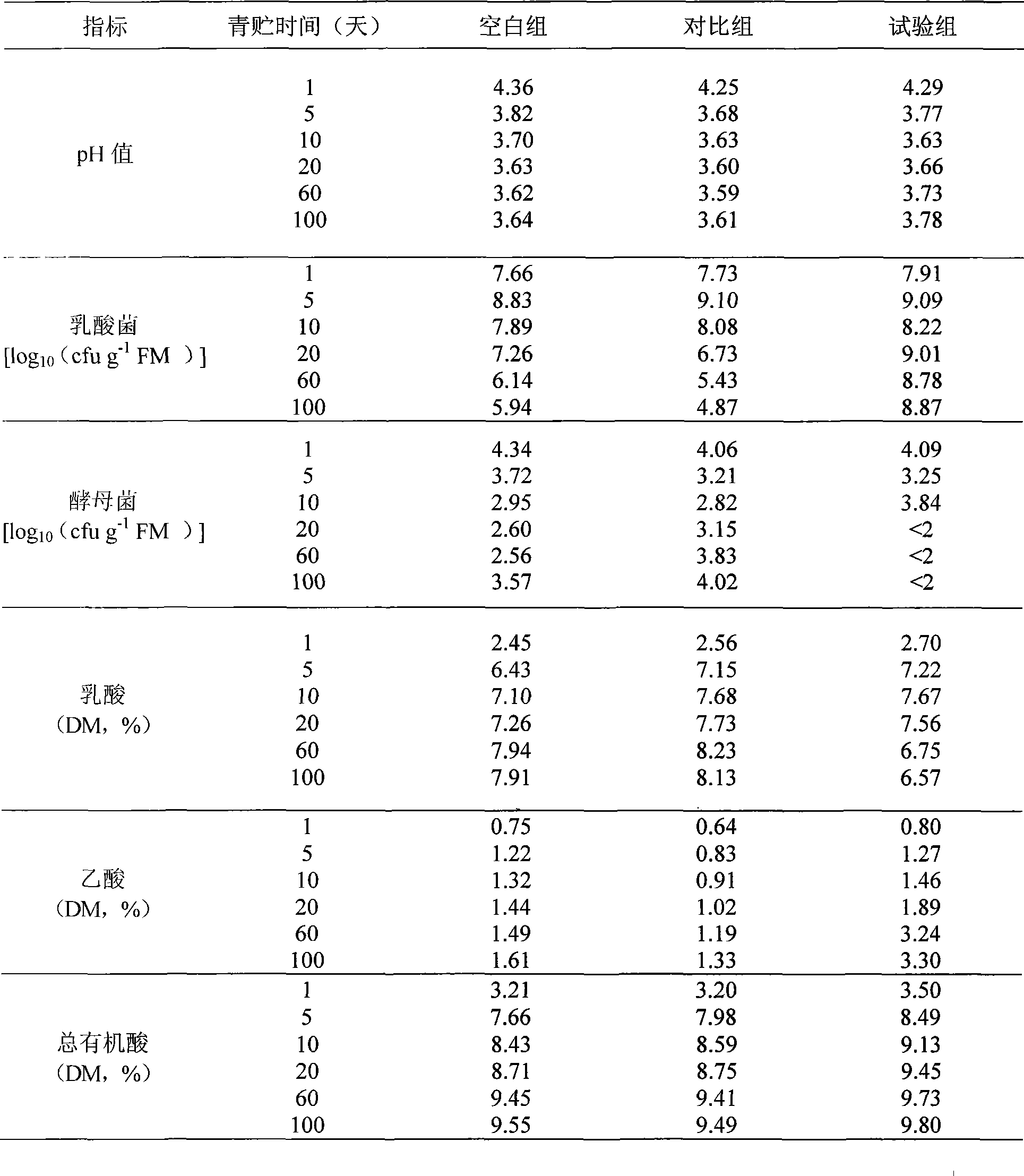

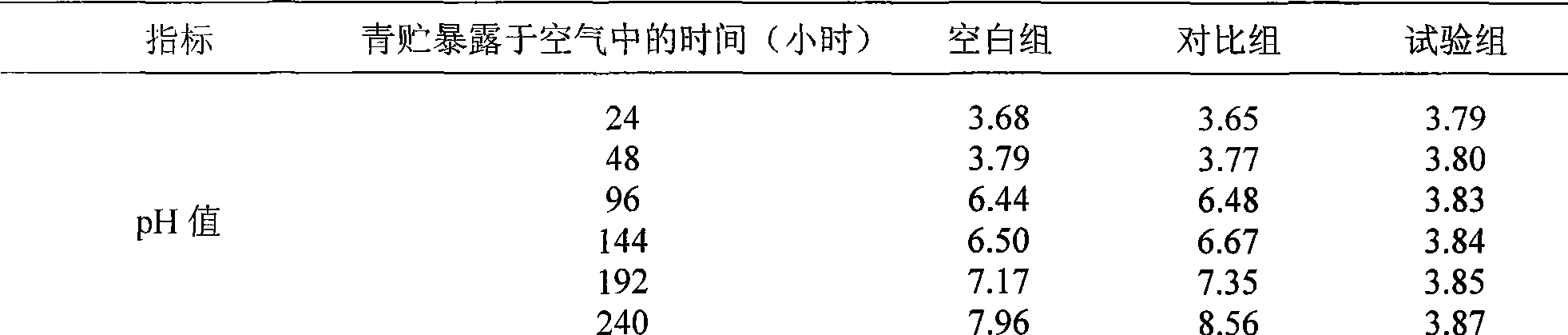

A technology of compound microorganisms and corn silage, which is applied in the field of corn silage inoculants, can solve the problems of secondary fermentation and corn silage instability, and achieve the effect of maintaining stable pH value, slow value increase, and increasing milk production and milk fat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of inoculant

[0020] The ratio of raw materials used is as follows:

[0021] Lactobacillus Brucella freeze-dried powder: 1 part by weight

[0022] Lactobacillus plantarum freeze-dried powder: 2 parts by weight

[0023] Skim milk powder: 30 parts by weight

[0024] Glucose: 60 parts by weight

[0025] Manganese sulfate: 7 parts by weight

[0026] Fully mix the lactic acid bacteria freeze-dried powder and the nutrient mixture evenly, pass through a 40-mesh sieve to obtain a powder with good fluidity, and the total number of Lactobacillus Brucella in the compound inoculum is 2×10 9 ~5×10 9 c Total number of Lactobacillus plantarum 5×10 9 ~7.5×10 9 cfu / g. Packed in paper-plastic or composite aluminum foil bags, the storage temperature is less than 35°C, the humidity of the storage environment is less than 60%, and the survival rate of lactic acid bacteria within one year is greater than 90%.

[0027] (2) How to use

[0028] The whole plant corn is...

Embodiment 2

[0030] (1) Preparation of inoculant

[0031] The ratio of raw materials used is as follows:

[0032] Lactobacillus Brucella freeze-dried powder: 2 parts by weight

[0033] Lactobacillus plantarum freeze-dried powder: 2 parts by weight

[0034] Skim milk powder: 30 parts by weight

[0035] Glucose: 58 parts by weight

[0036] Manganese sulfate: 8 parts by weight

[0037] Fully mix the lactic acid bacteria freeze-dried powder and the nutrient mixture evenly, pass through a 40-mesh sieve to obtain a fluid-type powder, and the total number of Lactobacillus Brucella in the compound inoculant is 5×10 9 ~8×10 9 cfu / g, the total number of Lactobacillus plantarum 7.5×10 9 ~1×10 10 cfu / g. Packed in paper-plastic or composite aluminum foil bags, the storage temperature is less than 35°C, the humidity of the storage environment is less than 60%, and the survival rate of lactic acid bacteria within one year is greater than 90%.

[0038] (2) How to use

[0039] Same as the method ...

Embodiment 3

[0041] (1) Preparation of inoculant

[0042] The ratio of raw materials used is as follows:

[0043] Lactobacillus Brucella freeze-dried powder: 3 parts by weight

[0044] Plantarum lyophilized powder: 4 parts by weight

[0045] Skimmed milk powder: 31 parts by weight

[0046] Glucose: 51 parts by weight

[0047] Manganese sulfate: 10 parts by weight

[0048]Fully mix the lactic acid bacteria freeze-dried powder and the nutrient mixture, and pass through a 40-mesh sieve to obtain a fluid-type powder. The total number of Lactobacillus Brucella in the compound inoculant is 8×10 9 ~1×10 10 cfu / g, total number of Lactobacillus plantarum 1×10 10 ~2×10 10 cfu / g. Packed in paper-plastic or composite aluminum foil bags, the storage temperature is less than 35°C, the humidity of the storage environment is less than 60%, and the survival rate of lactic acid bacteria within one year is greater than 90%.

[0049] (2) How to use

[0050] Same as the method of use in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com