Device for automatically adjusting dynamic balance of exposure roller

A technology of automatic adjustment and roller, which is applied in the direction of optics, optomechanical equipment, photoplate making process of patterned surface, etc., can solve the problems of dynamic imbalance and achieve the effect of reducing influence and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

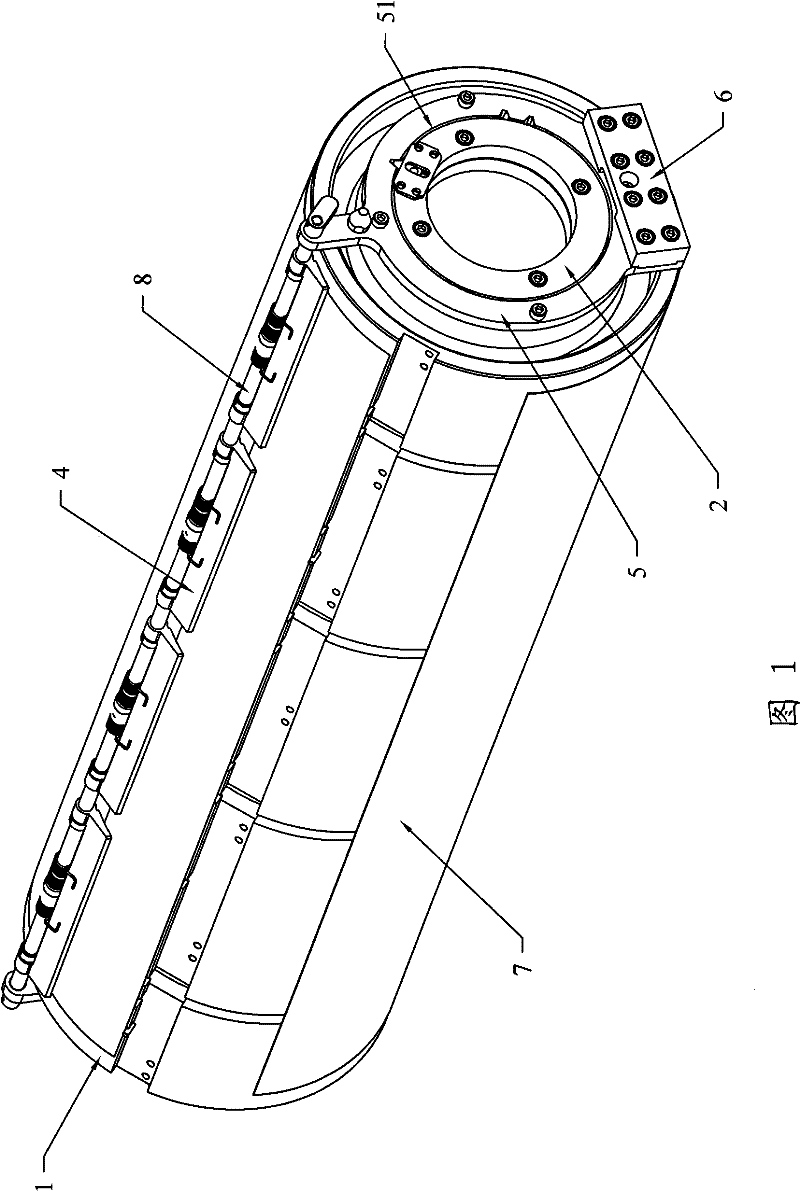

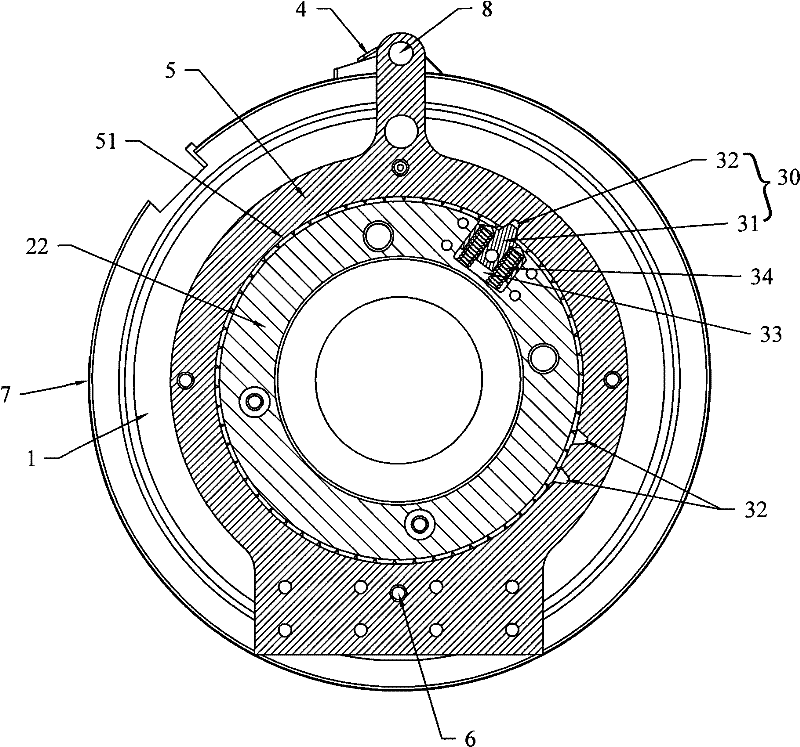

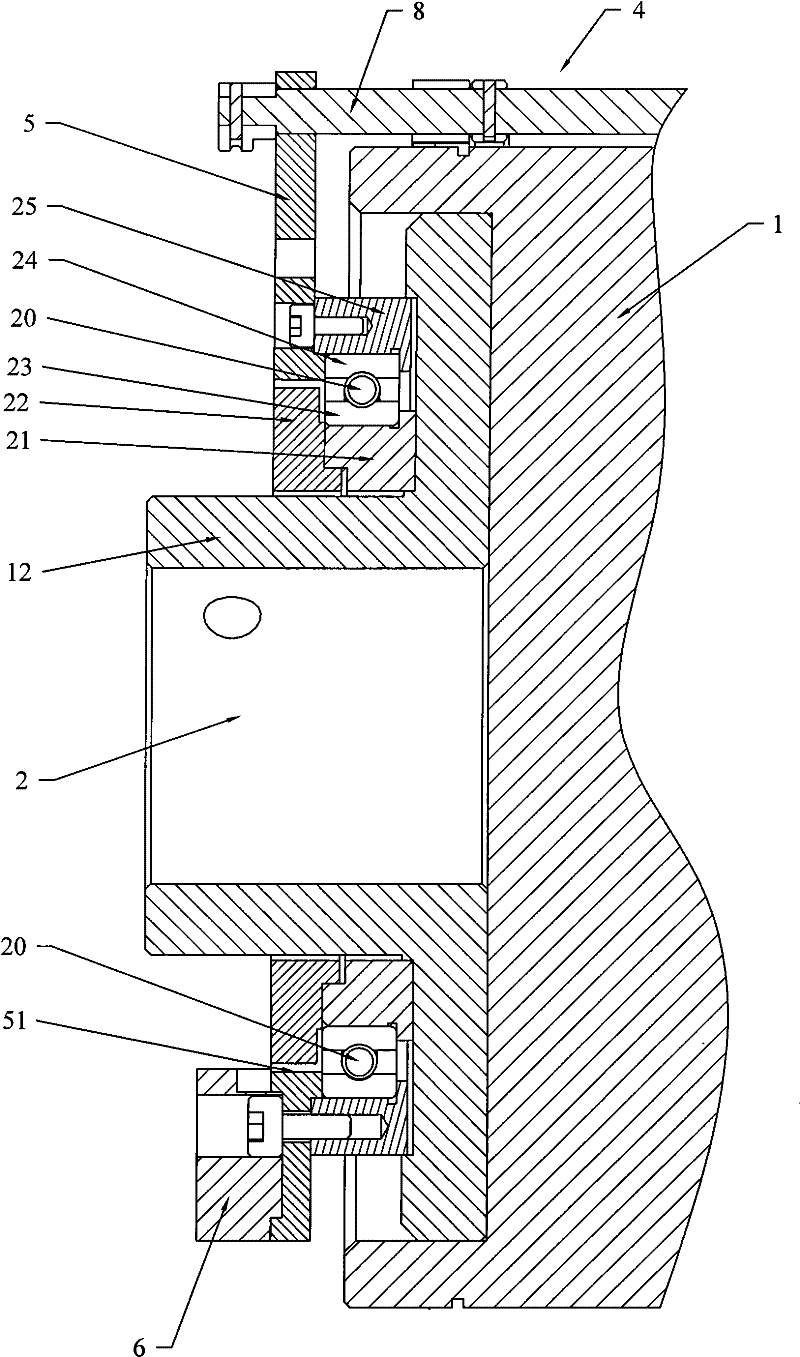

[0022] In computer plate making equipment, the exposure drum 1 is usually erected on a rotating shaft seat 3 through a rotating shaft 2 arranged in the center. Such as figure 1 , 2 As shown in 3, 4, in the preferred embodiment of the automatic adjusting device for the dynamic balance of the exposure drum according to the present invention, it includes a movable plate clamp 4, a connecting plate 5, a mass unit 6 and a positioning mechanism 30. The front edge of the printing plate 7 is fixed on the exposure drum 1, and the rear edge of the printing plate 7 is clamped by the movable plate clamp 4 so that the printing plate 7 is fixed on the drum surface of the exposure drum 1. The connecting plate 5 is rotatably connected with the exposure drum shaft 2 through the bearing 20. Specifically, the bearing inner ring bottom plate 21 can be fixed on the end cover 12 of the exposure drum, and the bearing inner ring cover plate 22 is abutted on the inner ring 23 of the bearing. The bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com