Test apparatus of DC gas insulated metal enclosed transmission line (GIL)

A gas-insulated metal and transmission line technology, applied in the direction of fault location, testing dielectric strength, etc., can solve the problems of failing to meet the DC GIL insulation test, etc., achieve the effect of reducing the amount of use, and the operation process of charging and discharging is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

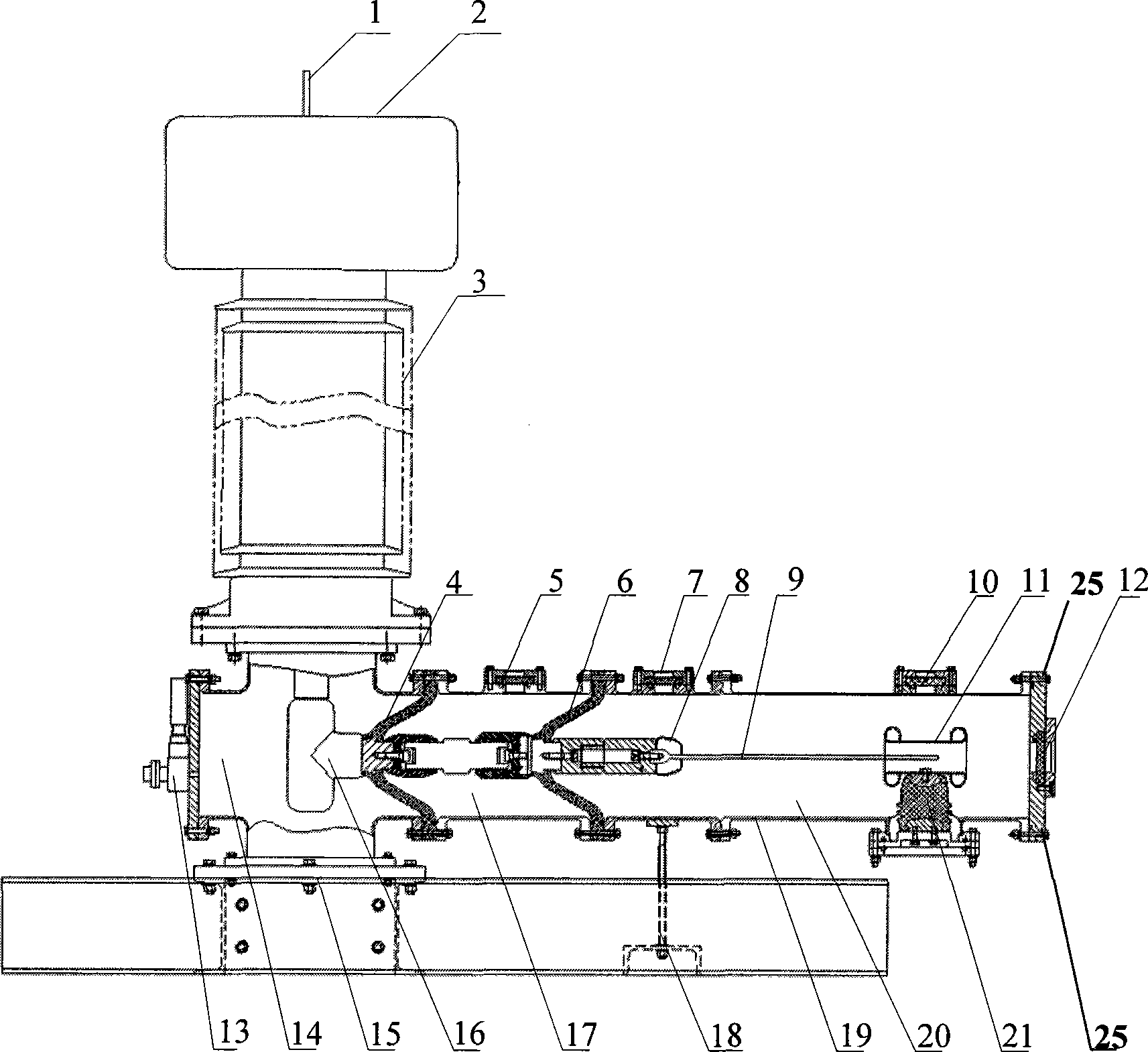

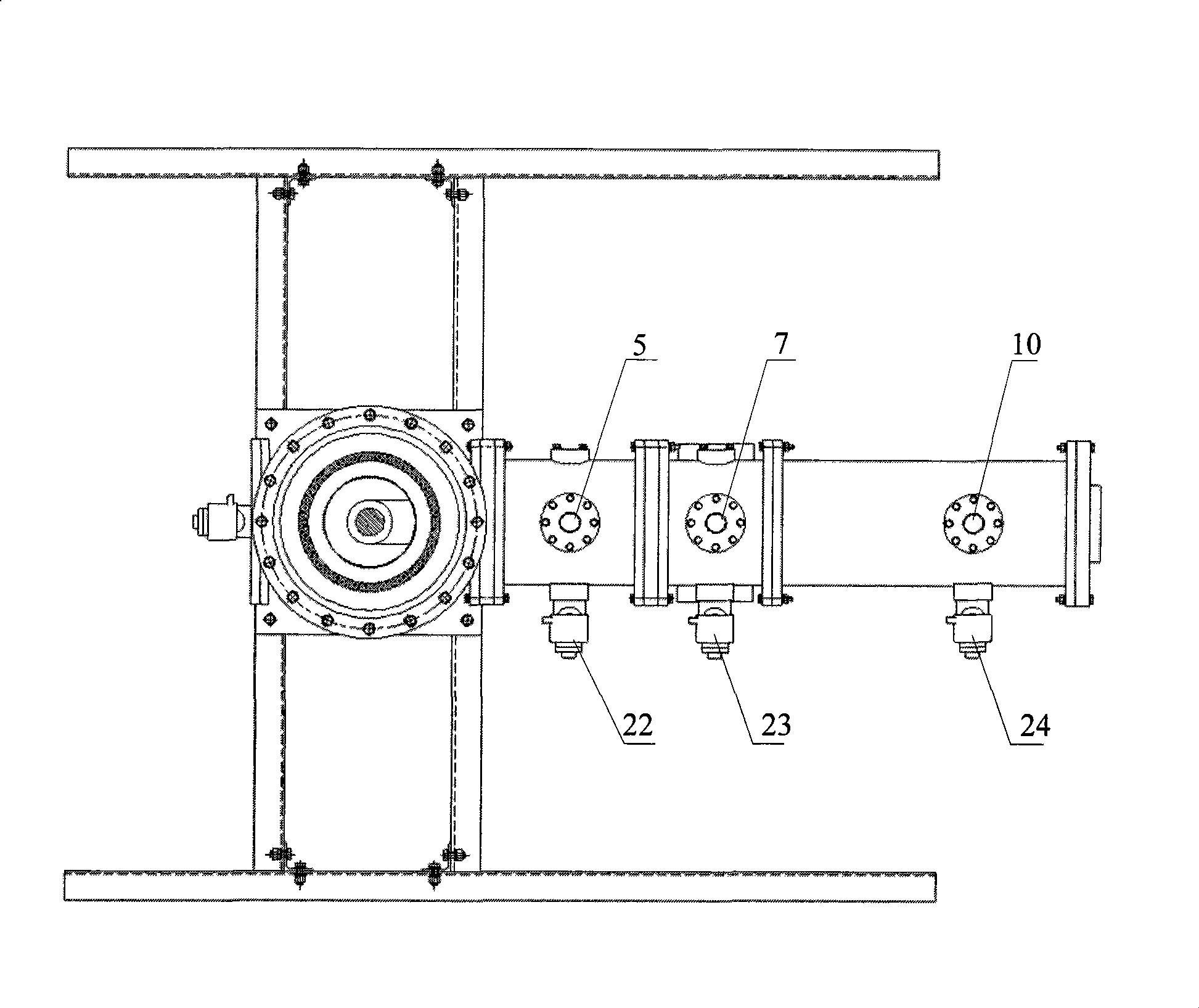

[0046] The following specifically describes the composition and structure of the experimental research device for direct current gas insulated metal enclosed transmission lines (GIL) according to the present invention. Such as figure 1 The overall structure of the device and figure 2 The top view of the device is shown.

[0047] Such as figure 1 As shown, the entire test device according to the present invention has a roughly "L" shape, which is provided with a high-voltage lead terminal 1, a high-voltage equalizing ring 2 and a high-voltage sleeve 3 of a silicone rubber composite insulator in the vertical direction. In the horizontal direction, the middle high-voltage lead electrode 9 and the test device housing 19 are coaxially distributed. The unit module No. 1 air chamber 14, No. 2 air chamber 17, and No. 3 air chamber 20 form a horizontal test device housing 19, of which 1 No. 14 air chamber is arranged vertically, and No. 2 air chamber 17 and No. 3 air chamber 20 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com