Continuously adjustable mechanical hydraulic valve lift device

A gas valve lift, mechanical hydraulic technology, applied in valve devices, non-mechanically actuated valves, mechanical equipment, etc., can solve the problems of too many followers, the inability to control the valve opening time, and complex processing. Achieve the effect of improving economy, reducing pumping loss and increasing charge coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

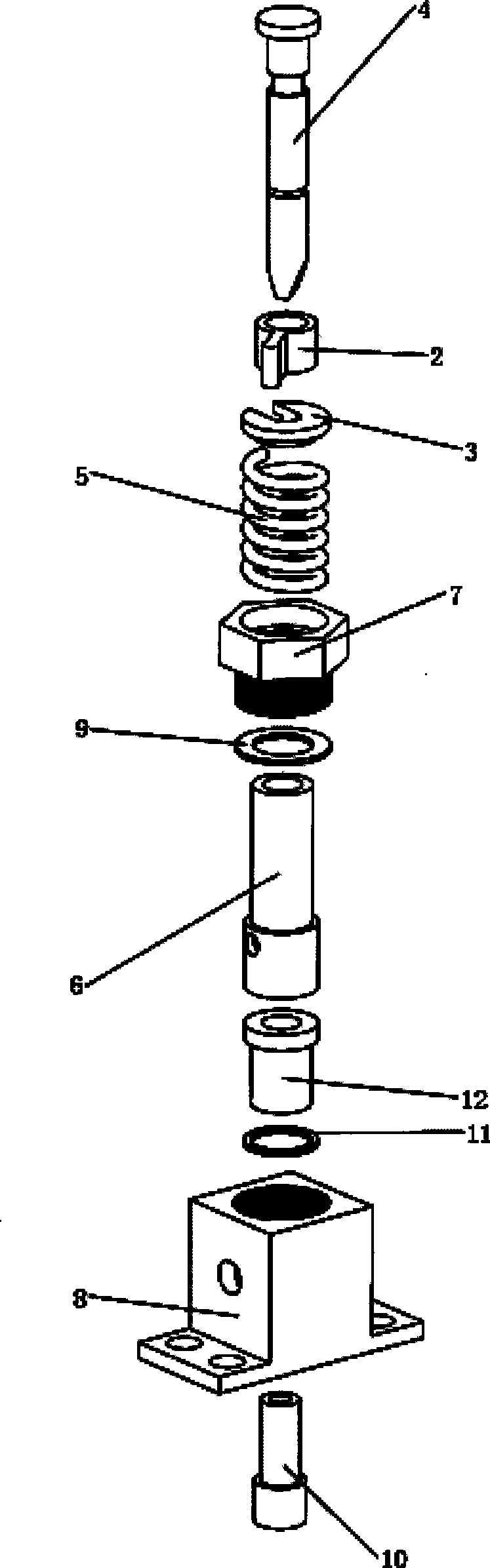

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 with figure 2 As shown, the present invention includes gas distribution cam 1, valve 13, valve spring 14, plunger adjustment arm 2, plunger spring seat 3, tappet plunger 4, plunger spring 5, tappet plunger sleeve 6, locking Nut 7, low-pressure oil cylinder 8, first gasket 9, execution plunger 10, second gasket 11, execution plunger sleeve 12; plunger adjustment arm 2 is installed on the shaft shoulder of tappet plunger 4, and The plunger 4 is interference fit, and the tappet plunger 4 is directly driven by the gas distribution cam 1; the head of the tappet plunger 4 has two oblique sections that are symmetrical along the axis, and its symmetry plane is the same as that of the plunger adjustment arm 2 along the axis. The plane of symmetry coincides; the plunger spring seat 3 is installed close to the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com