Construction method for decomposing grading high-rise pile cap

A construction method and a technology for decomposing trenches, which are applied in filling, infrastructure engineering, construction, etc., can solve the problems of reducing the bearing capacity of piles, negative friction, and inability to compact the secondary backfill, so as to shorten the construction period and solve the problems of construction. Difficulty, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

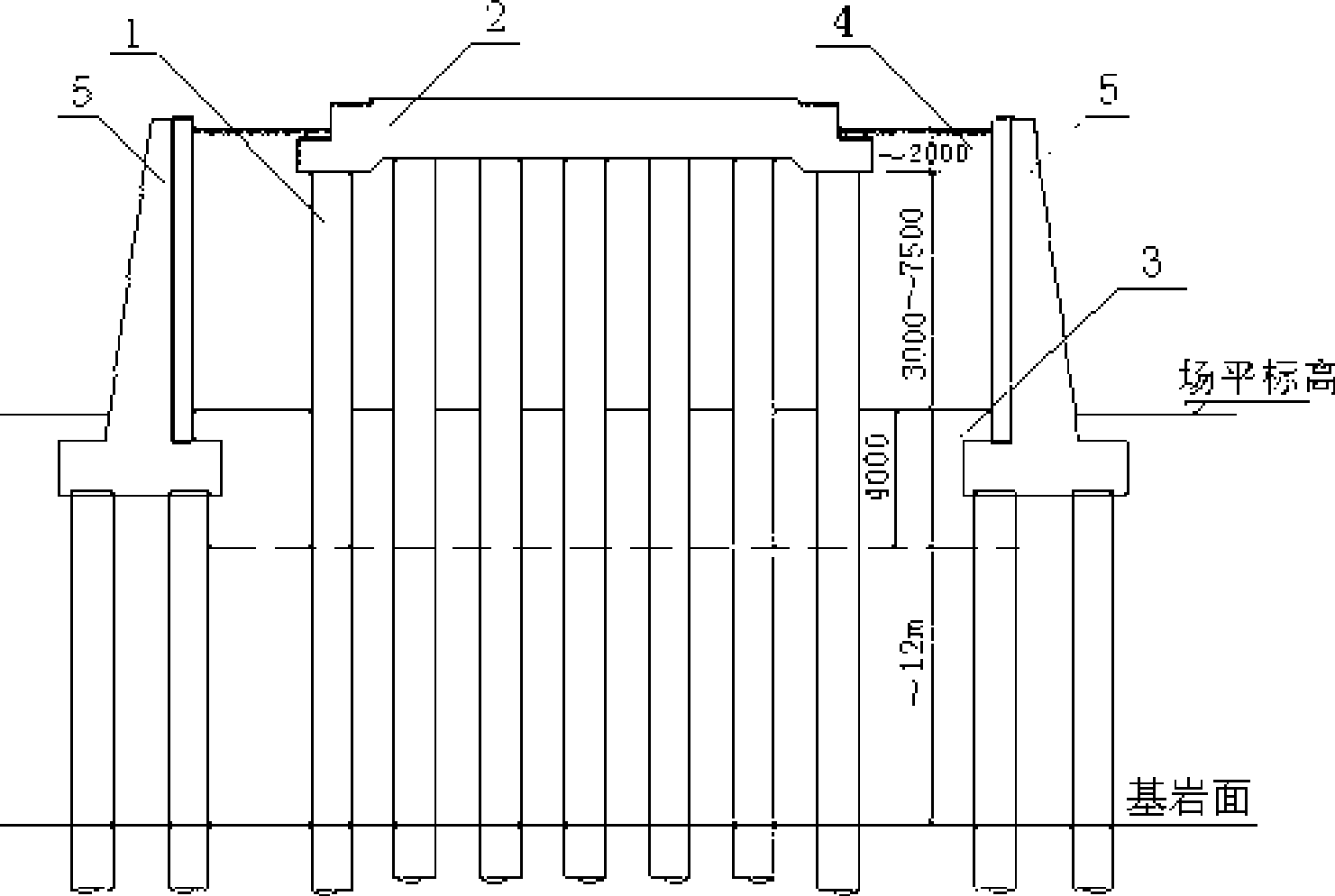

[0011] The construction procedure of the present invention is that the pile 1 under the foundation of the construction groove is to the design elevation after the field is leveled, and then the pile cap 2 is constructed, and the ground 3 to 4 meters deep under the field leveling elevation is treated with normal pressure spray grout after the construction of the cap 2 is completed. Backfill soil 3. The backfill soil 4 on the upper part of the field level elevation and the surrounding retaining wall 5 have been cancelled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com