Ultra high temperature lubricating grease and production method thereof

A kind of grease, ultra-high temperature technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of smoke, easy dripping, loss, etc., to prevent sintering, prolong service life, good high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

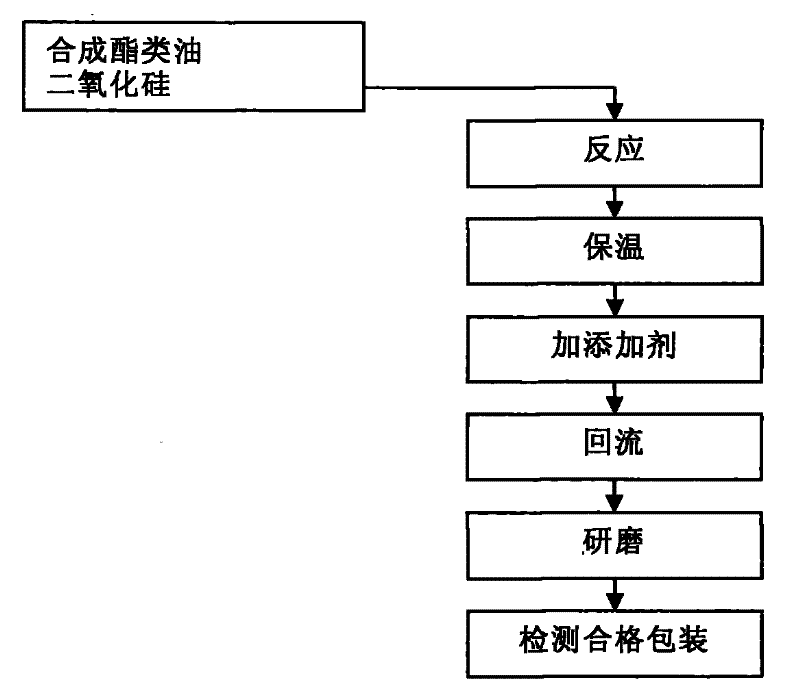

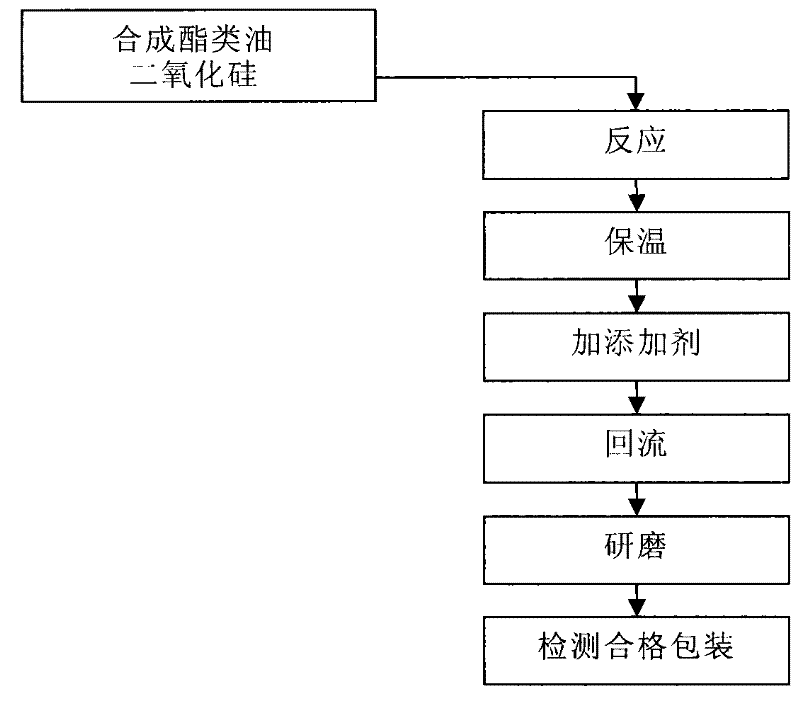

Method used

Image

Examples

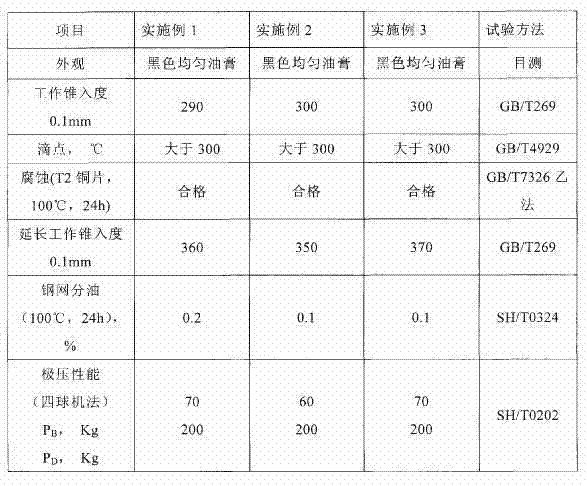

Embodiment 1

[0021] Embodiment one: the production method of a kind of ultra-high temperature lubricating grease of the present invention adopts the following process steps: its component ratio is counted by weight parts:

[0022] Take synthetic ester oil: 50 parts, lipophilic silica powder: 10 parts, eutectic rolling ball: 1 part, colloidal graphite: 30 parts, copper powder: 7.9 parts, boron nitride: 1 part , Dialkyl diphenylamine is 0.1 part, and the above formula is a component of the ultra-high temperature lubricating grease of the embodiment of the present invention.

[0023] Add synthetic ester oil and silicon dioxide powder into the open reaction kettle, start stirring after adding, stirring speed: 30 rpm; stirring time: 30 minutes; heat up to 120°C; heat preservation reaction for 1 hour (stirring is not stopped); After the heat preservation is over, stop stirring, add eutectic rolling balls, colloidal graphite, copper powder, boron nitride, dialkyl diphenylamine, start stirring, st...

Embodiment 2

[0026] A production method of ultra-high temperature lubricating grease of the present invention adopts the following process steps: the component ratio is calculated in parts by weight:

[0027] Take synthetic ester oil: 65 parts, lipophilic silica powder: 14 parts, eutectic rolling ball: 2 parts, colloidal graphite: 14 parts, silver powder: 2.8 parts, boron nitride: 2 parts, Dialkyl diphenylamine is 0.2 parts, and the above formula is the ultra-high temperature lubricating grease component of the present invention.

[0028] Add synthetic ester oil and silicon dioxide powder into the open reaction kettle, start stirring after adding, stirring speed: 30 rpm; stirring time: 30 minutes; heat up to 100°C; heat preservation reaction for 1.5 hours (stirring is not stopped); After the heat preservation is over, stop stirring, add eutectic rolling balls, colloidal graphite, copper powder, boron nitride, dialkyl diphenylamine, start stirring, stirring speed: 20 rpm; stirring time: 30 ...

Embodiment 3

[0029] Embodiment three: the production method of a kind of ultra-high temperature lubricating grease of the present invention adopts following process steps: its component ratio is counted by weight parts:

[0030] Take synthetic ester oil: 80 parts, lipophilic silica powder: 16 parts, eutectic rolling ball: 1 part, colloidal graphite: 1 part, gold powder: 0.7 parts, boron nitride: 1 part, 0.3 part of dialkyl diphenylamine is the ultra-high temperature lubricating grease component of the present invention.

[0031] Add synthetic ester oil and silicon dioxide powder into the open reaction kettle, start stirring after adding, stirring speed: 30 rpm; stirring time: 30 minutes; heat up to 150°C; heat preservation reaction for 2 hours (stirring is not stopped); After the heat preservation is over, stop stirring, add eutectic rolling balls, colloidal graphite, copper powder, boron nitride, dialkyl diphenylamine, start stirring, stirring speed: 20 rpm; stirring time: 30 minutes; aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com