Ecological fish breeding installation with purified recirculated water

An ecological purification and circulating water technology, applied in fish farming, biological water/sewage treatment, energy and wastewater treatment, etc., can solve the hidden dangers of inlet and drainage pipes and ditches, large area of water inlet and outlet ditches, economical and ecological benefits low problems, to achieve the effect of resource utilization, feed saving, and optimization of water flow direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

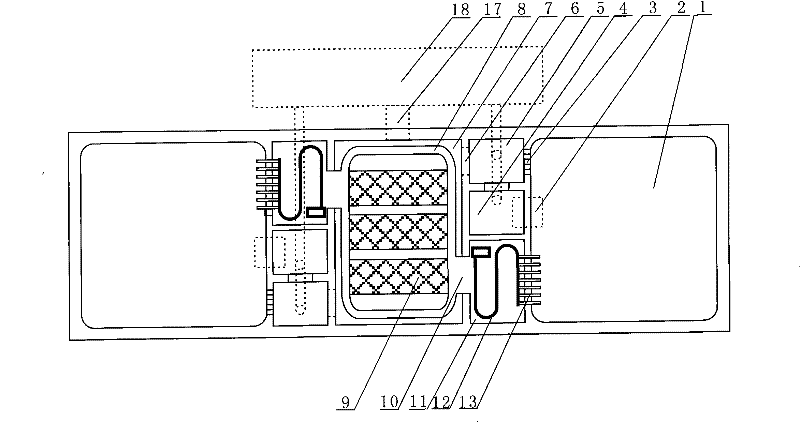

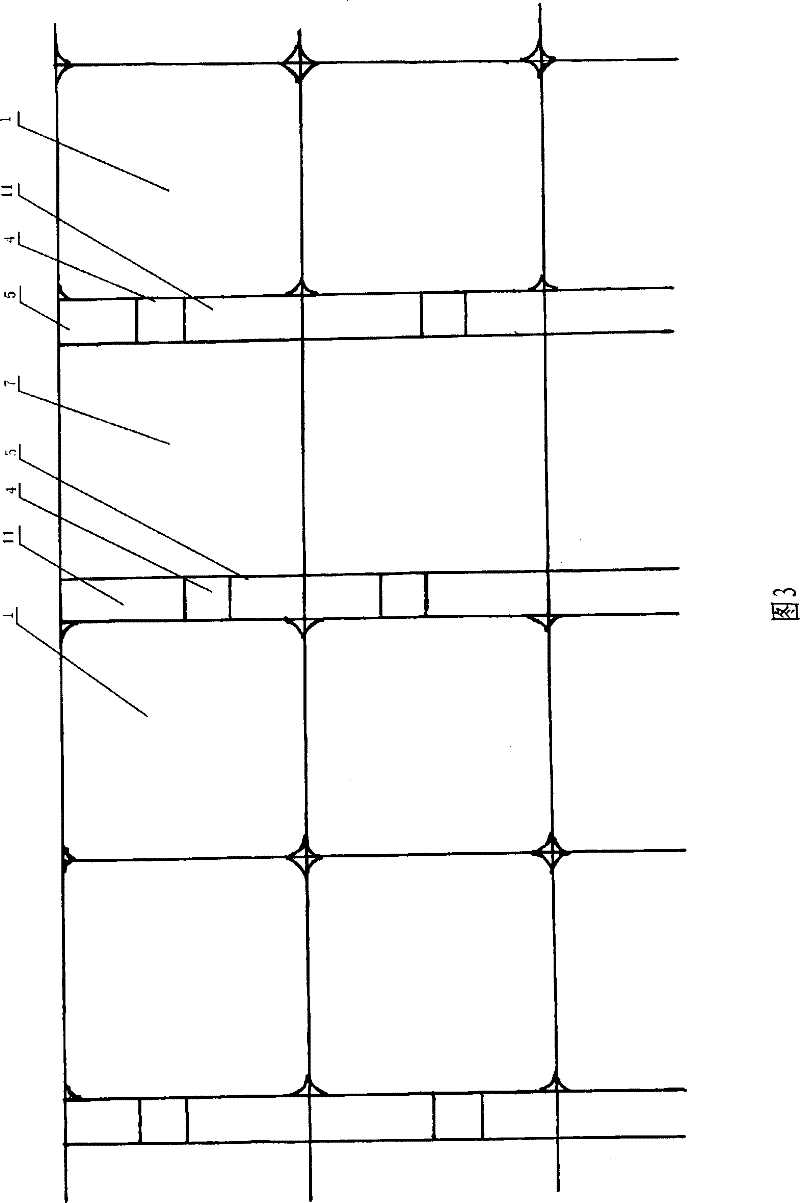

[0024] 1. Factory buildings: Plastic greenhouses or brick-concrete structures can be used. The roof is divided into two parts: the light-transmitting area (above the water treatment pool) and the shading area (above the fish pond 1). 22 are built on the fish pond 1 as a shading area.

[0025] 2. Fish pond: its depth is 2m, and it is connected with the primary sedimentation tank 4 by the drainage hole 2 on the bottom wall of the fish pond. Drain into the water hole 13.

[0026] 3. Multi-functional water treatment pool: long strip shape, composed of primary sedimentation tank 4, secondary foam separation tank 5 and water collection tank 11. The residue and dirt deposited in the bottom of the primary sedimentation tank 4 are directly discharged into the biogas digester 18 . The primary treated pool water overflows into the secondary foam separation tank 5. The foam water entrained on the surface of the fish pond 1 flows into the secondary foam separation tank 5 through the wat...

Embodiment 2

[0032] According to the design requirements of the present invention, fish culture facility is built, and commercial sturgeon culture test has been carried out, specifically as follows:

[0033] 1. Facilities construction and equipment and equipment installation

[0034] 1.1 Fish pond 1: It is octagonal, with a length and width of 11 meters, a depth of 2 meters, and an area of 120 meters 2 , volume 240m 3 , consists of two equivalent fish ponds and a water treatment pond.

[0035]1.2 Multifunctional water treatment pool: it is long and divided into three small pools, the primary sedimentation tank is 2×2×3m with an area of 4m 2 , volume 12m 3 ;Secondary foam separation pool 3.5×2×3m, area 7m 2 , volume 21m 3 ;Collecting pool 5.5×2×3m, area 11m 2 , volume 33m 3 .

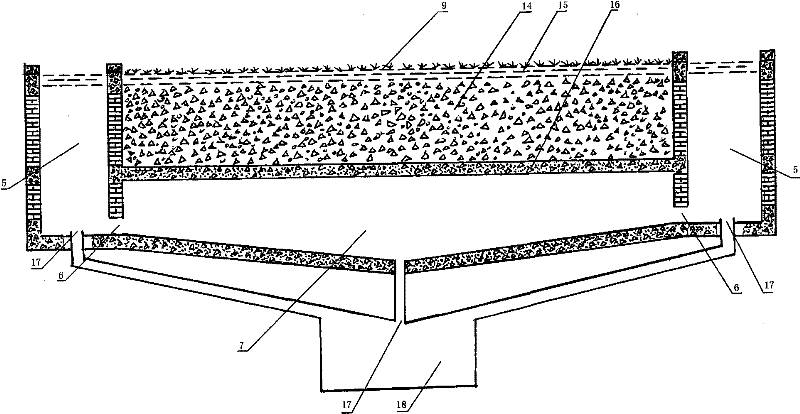

[0036] 1.3 Constructed wetland biofilter 7: square, 11m in length and width, 3m in depth, and 121m in area 2 , volume 363m 3 . Cement partitions are installed deep in the pool, and filter materials suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com