Method of preparing high-performance TiO2 nanometer photocatalystic material

A titanium dioxide and nanomaterial technology, which is applied in the field of preparation of high-performance titanium dioxide nanometer photocatalytic materials, can solve the problems of complex preparation steps, the photocatalytic degradation efficiency needs to be improved, etc., and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0016] The preparation of embodiment 1 titanium dioxide nanoribbon flower:

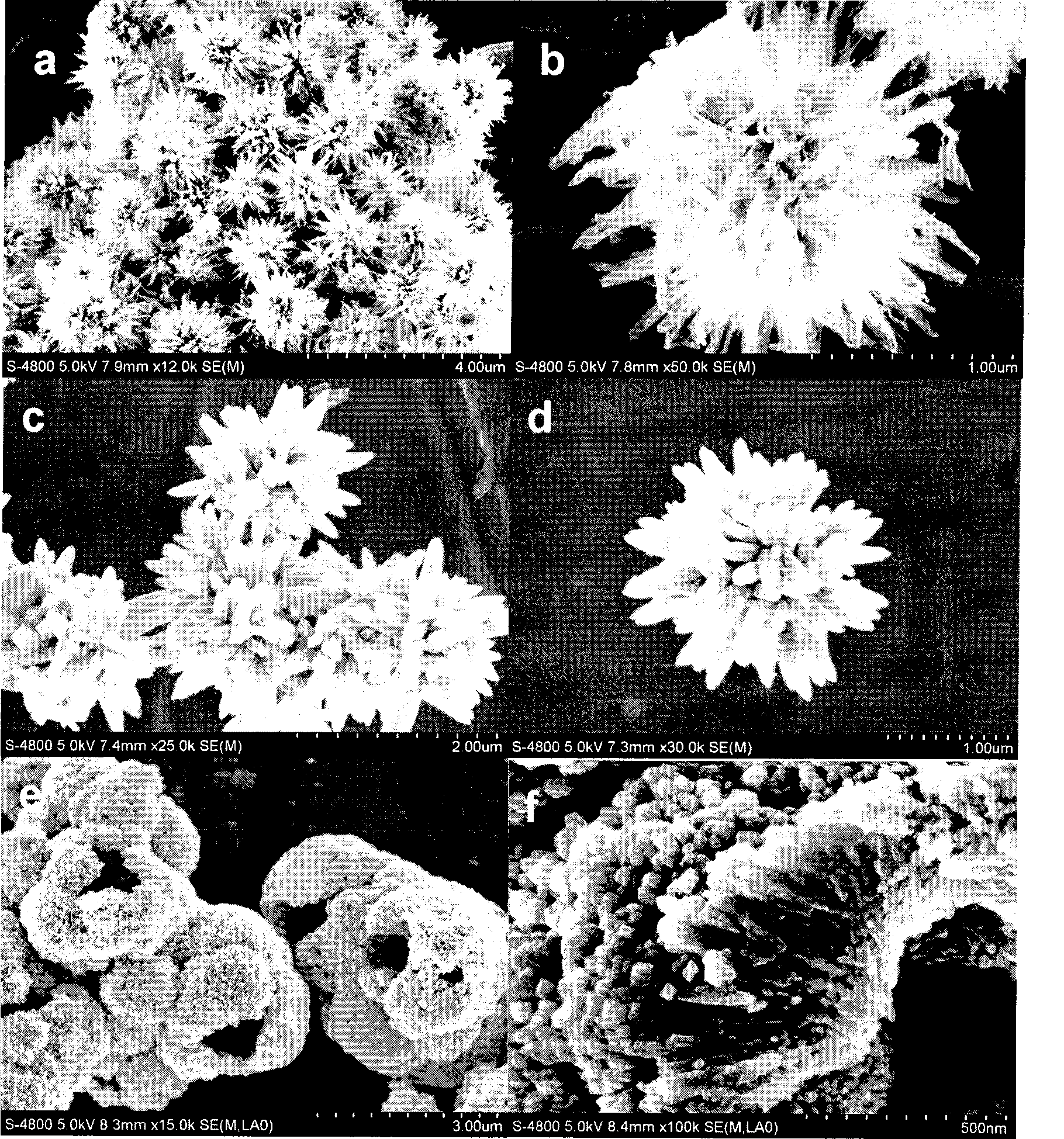

[0017] With 15mL 0.06mol / L potassium titanium oxalate (PTO) aqueous solution as the mother liquor, take PTO and H 2 o 2 The molar ratio of the mixed solution is 1:200. After the mixed solution is completely reacted, continue to stir for 10 minutes, transfer the obtained solution to a high-pressure reactor, heat it at 150°C for 0.5h, and then cool it to room temperature naturally. ℃ drying for 3 hours to obtain titanium dioxide nanorod flower material (see figure 1 a, figure 1 b).

Embodiment 2 2

[0018] The preparation of embodiment 2 titanium dioxide nano-rod-shaped flowers:

[0019] With 15mL 0.06mol / L potassium titanium oxalate (PTO) aqueous solution as the mother liquor, take PTO and H 2 o 2 The molar ratio of the mixed solution is 1:2000. After the reaction of the mixed solution is complete, continue to stir for 10 minutes, transfer the obtained solution to a high-pressure reactor, heat it at 200°C for 5 hours, and then cool it to room temperature naturally. Dry 3h to get titanium dioxide nanorod-shaped flower material (see figure 1 c, figure 1 d).

Embodiment 3 2

[0020] Embodiment 3 Preparation of titanium dioxide nanorod self-assembled hollow spheres:

[0021] With 15mL 0.06mol / L potassium titanium oxalate (PTO) aqueous solution as mother liquor, according to PTO and H 2 o 2 The molar ratio was 1:200, and 0.18mol H was added dropwise to the PTO solution 2 o 2 , After the dropwise addition is completed and stirred for 0.5h, the resulting solution is transferred into the reactor, heat-treated at 150°C for 5h and cooled naturally, and the resulting precipitate is cleaned and dried in a constant temperature drying oven at 60-70°C for 3h to obtain a self-assembled hollow titanium dioxide nanorod. ball material (see figure 1 e, figure 1 f).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com