Tool head, machine tool and boring method of bore of cylinder block using the machine tool

A technology of a machine tool and a cutter head, which is applied in the field of cutter head, machine tool and boring cylinders using the machine tool, can solve the problem that the rough grinding head 502 and the fine grinding head 504 cannot be rapidly expanded and cannot have too many changes. and other problems, to achieve the effect of simple structure and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

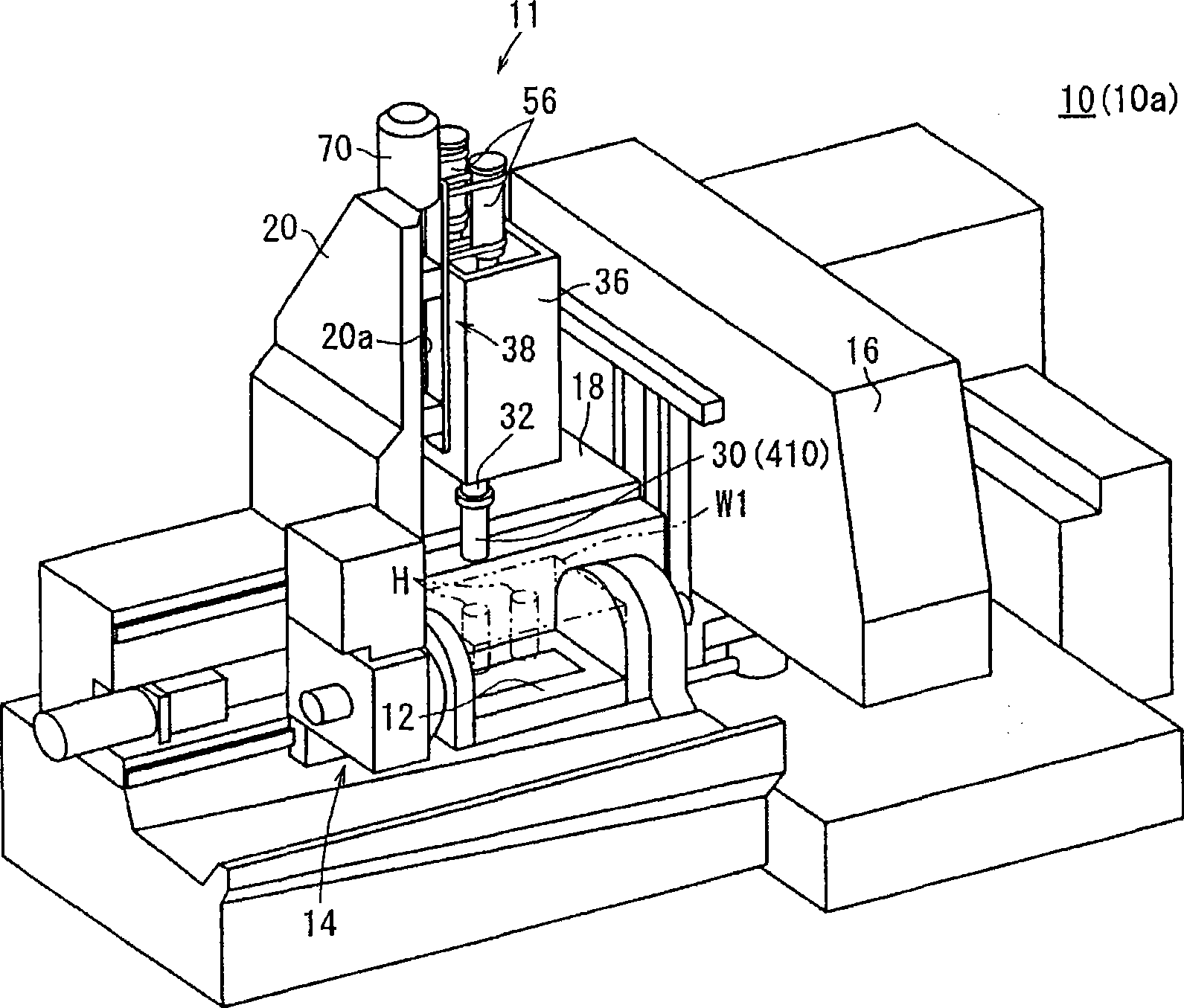

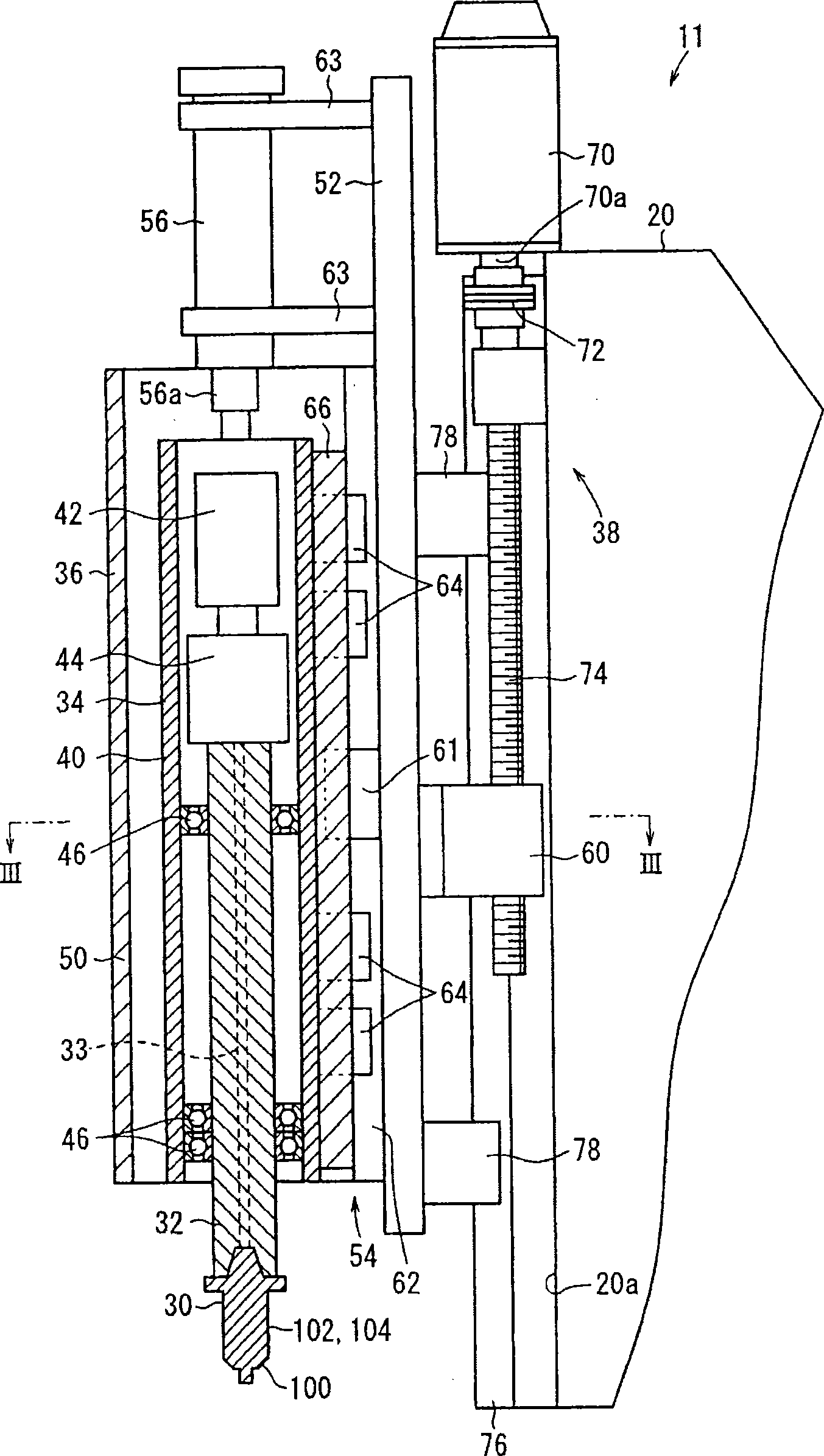

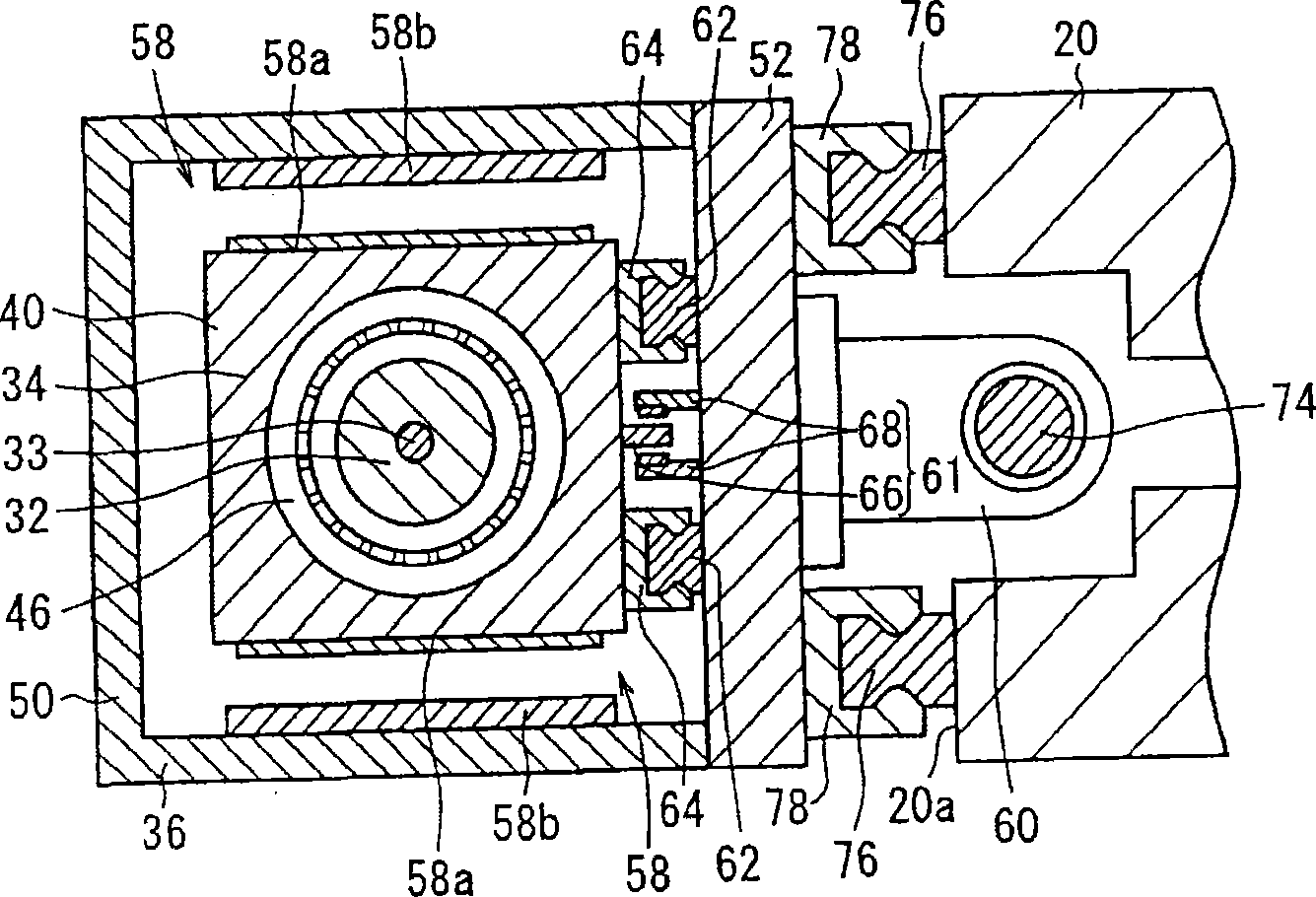

[0088] A machine tool according to an embodiment of the present invention will be described below with reference to the drawings.

[0089] as in figure 1 As shown in , the combined machine tool 10 according to the first embodiment of the present invention is arranged in a production line for machining a cylinder, for example, a cylinder of an internal combustion engine of an automobile forming a workpiece W1. The machine tool 10 has a spindle actuator assembly 11 for actually boring and honing (grinding) a workpiece W1, a workpiece loader in front of the machine tool, and a pallet 12 for conveying a workpiece on which the workpiece is placed and fixedly mounted. A workpiece conveying mechanism 14 reciprocally movable between the lower portion of the spindle actuator assembly 11 , and a monitoring console 16 for electronically controlling the spindle actuator assembly 11 and the workpiece conveying mechanism 14 . The machine tool 10 is arranged as a system in a production lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com