Novel dual-color side-by-side composite polyester fiber

A composite polyester and composite fiber technology, applied in the field of polyester fibers, can solve the problems of not conforming to the principle of green environmental protection, the mixed fabric affects the recycling, easy to pollute the environment, etc., and achieves improved dyeing function, good dimensional stability, ironing, etc. The effect of low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

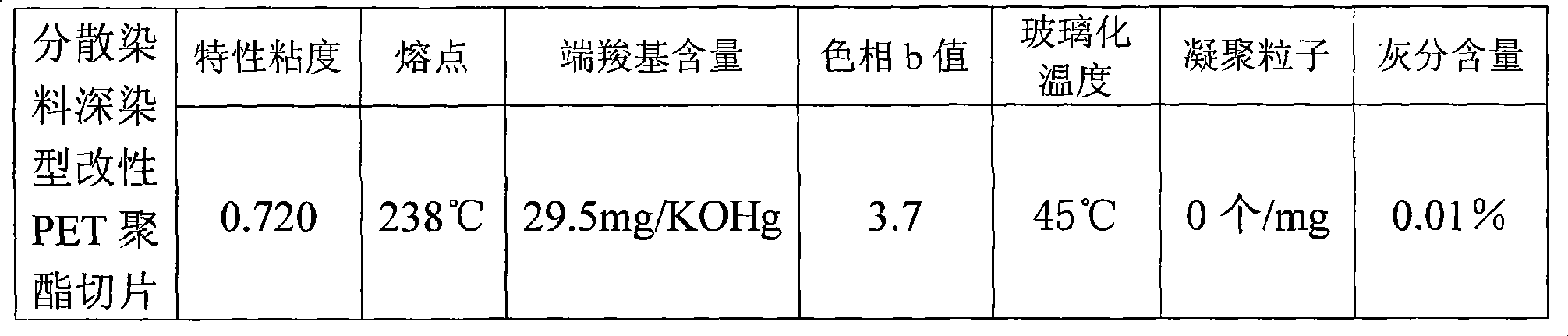

Embodiment 1

[0026] The specified amount of semi-dull PBT polyester chips is directly transported to the chip drying tower, the drying temperature is controlled at 130°C, and the drying time is controlled for 4 to 5.5 hours. The moisture content in the chips is tested. After reaching the drying standard, start the screw of the spinning equipment 1. Carry out chip spinning, see the above Table 2 for the temperature control of each zone of the spinning screw and the temperature control of the elbow and the box. Pre-crystallize the specified amount of disperse dye deep-dyed PET polyester slices at normal pressure, and control the pre-crystallization temperature at 130-136°C for 2.5-3.5 hours, and then dry it at a temperature of 150-155°C for 5-5 hours. After 6.5 hours, test the moisture content in the slices. After reaching the drying standard, start the second screw of the spinning equipment to spin the slices. The temperature of each area of the spinning screw and the temperature control o...

Embodiment 2

[0028] The specified amount of semi-dull PBT polyester chips is directly transported to the chip drying tower, the drying temperature is controlled at 130°C, and the drying time is controlled for 4 to 5.5 hours. The moisture content in the chips is tested. After reaching the drying standard, start the screw of the spinning equipment 1. Carry out chip spinning, see the above Table 2 for the temperature control of each zone of the spinning screw and the temperature control of the elbow and the box. Pre-crystallize the specified amount of disperse dye deep-dyed PET polyester slices at normal pressure, and control the pre-crystallization temperature at 130-136°C for 2.5-3.5 hours, and then dry it at a temperature of 150-155°C for 5-5 hours. After 6.5 hours, test the moisture content in the slices. After reaching the drying standard, start the second screw of the spinning equipment to spin the slices. The temperature of each area of the spinning screw and the temperature control o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com