Technique for calcining native copper

A process method, the technology of natural copper forging, applied in the field of traditional Chinese medicine, can solve the problems of unfavorable large-scale production, uneven quality, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A kind of optimal forging process of natural copper, it is characterized in that process method step is as follows

[0056] (1) Break the natural copper into small pieces of 9 to 10 mm, wash and dry, and place the mat in a crucible with a thickness of 2 cm;

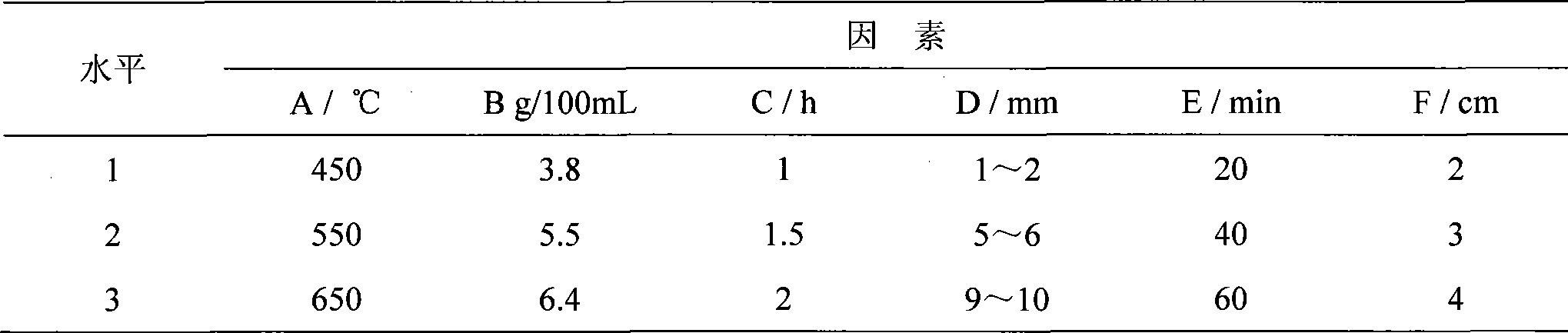

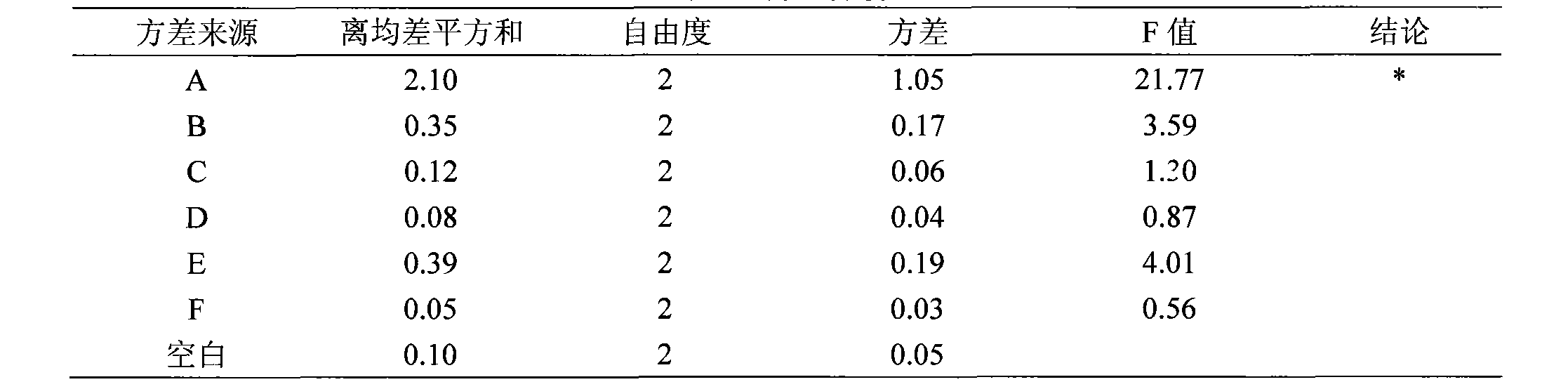

[0057] (2) According to natural copper calcination temperature (450℃, 550℃, 650℃), vinegar concentration (3.8g / 100mL, 5.5g / 100mL, 6.4g / 100mL), calcination time (1h, 1.5h, 2h) , program heating time (20min, 40min, 60min), medicinal material particle size 1-2mm, 5-6mm, 9-10mm, bedding thickness 2cm, 3cm, 4cm six investigation factors, take 3 levels for each factor, choose L18( 3 7 ) Orthogonal table arrangement test, according to the orthogonal test scheme, the natural copper obtained in the previous step is forged (seeing shown in Table 1);

[0058] (3) Measure the relative hardness, porosity, and Fe in the water decoction of the calcined natural copper obtained in the previous step. 2+ The method of As content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com