Ceramic electric pressure cooker

A technology of electric pressure cooker and ceramics, which is applied in the direction of pressure cooker, cooking utensils, household utensils, etc. It can solve the problems of large tolerance and difficulty in mass production, and achieve the effect of safe use and shortened heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

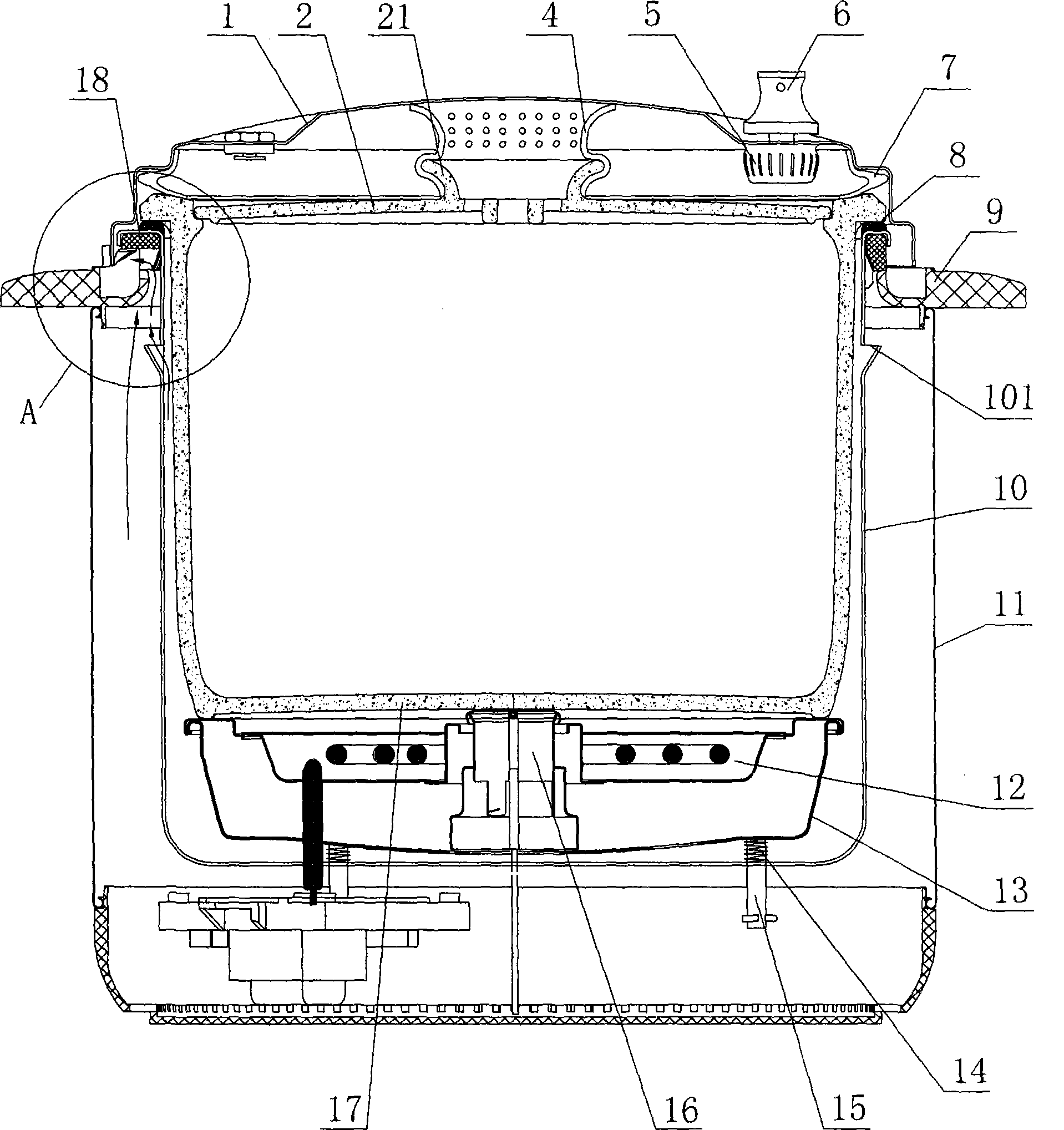

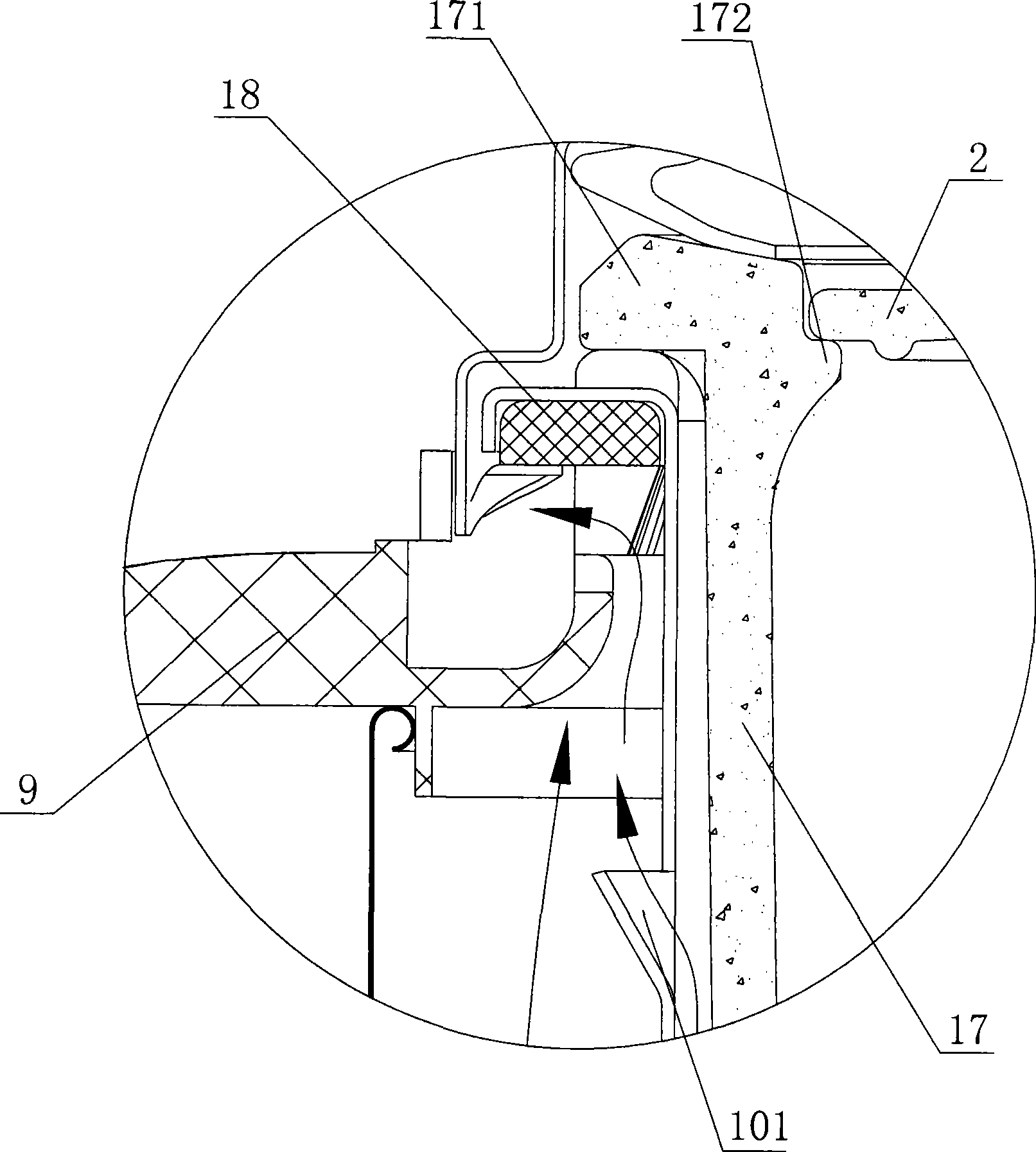

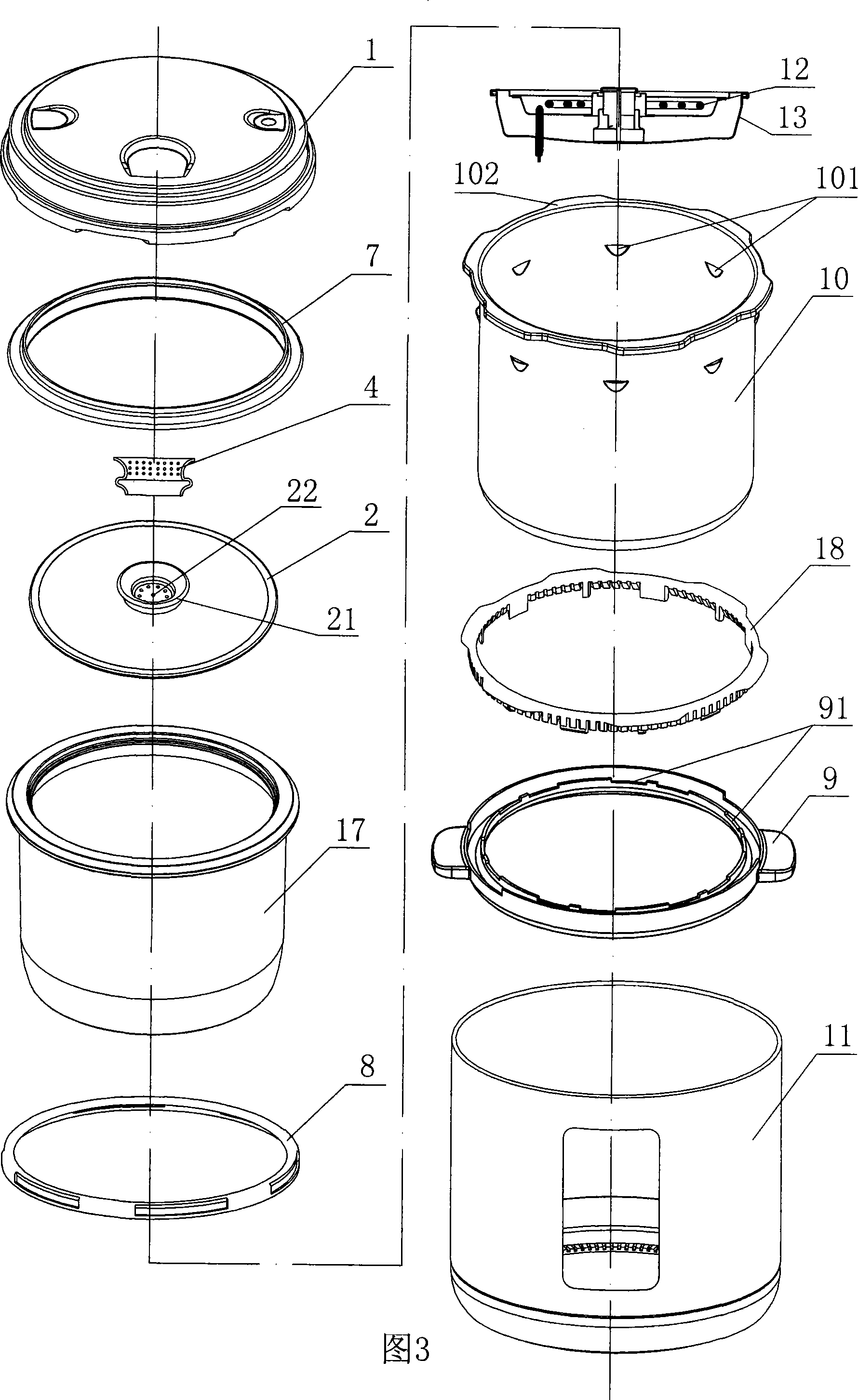

[0016] Such as figure 1 Shown to 3, it is a kind of ceramic electric pressure cooker, comprises casing 11, ceramic container 17, pot cover 1, nylon ring 18, middle ring 9, the seal ring 7 that is located in the pot cover and seals it with ceramic container, electric Heating device 12, the anti-blocking cover 5 that is located in the pot cover, the safety valve 6 that is located on the anti-blocking cover outlet pipe, the metal sleeve 10 that is fixed in the shell 11. The electric heating device 12 is located in the metal sleeve and is located at the bottom. The pot cover 1 is buckled and fitted with the metal sleeve. The opening of the metal sleeve is provided with an outwardly bent supporting edge 102. The middle ring 9 is fixed on the metal sleeve. The container 17 is located in the metal sleeve, and an outwardly bent flange 171 is provided at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com