Assembling tool setup for automobile bunch product

A technology for assembling tooling and automobile wiring harnesses. It is applied in the installation of cables, cable installation devices, electrical components, etc., which can solve the problems of scrapped tooling, low efficiency, and easy displacement of wiring harnesses. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

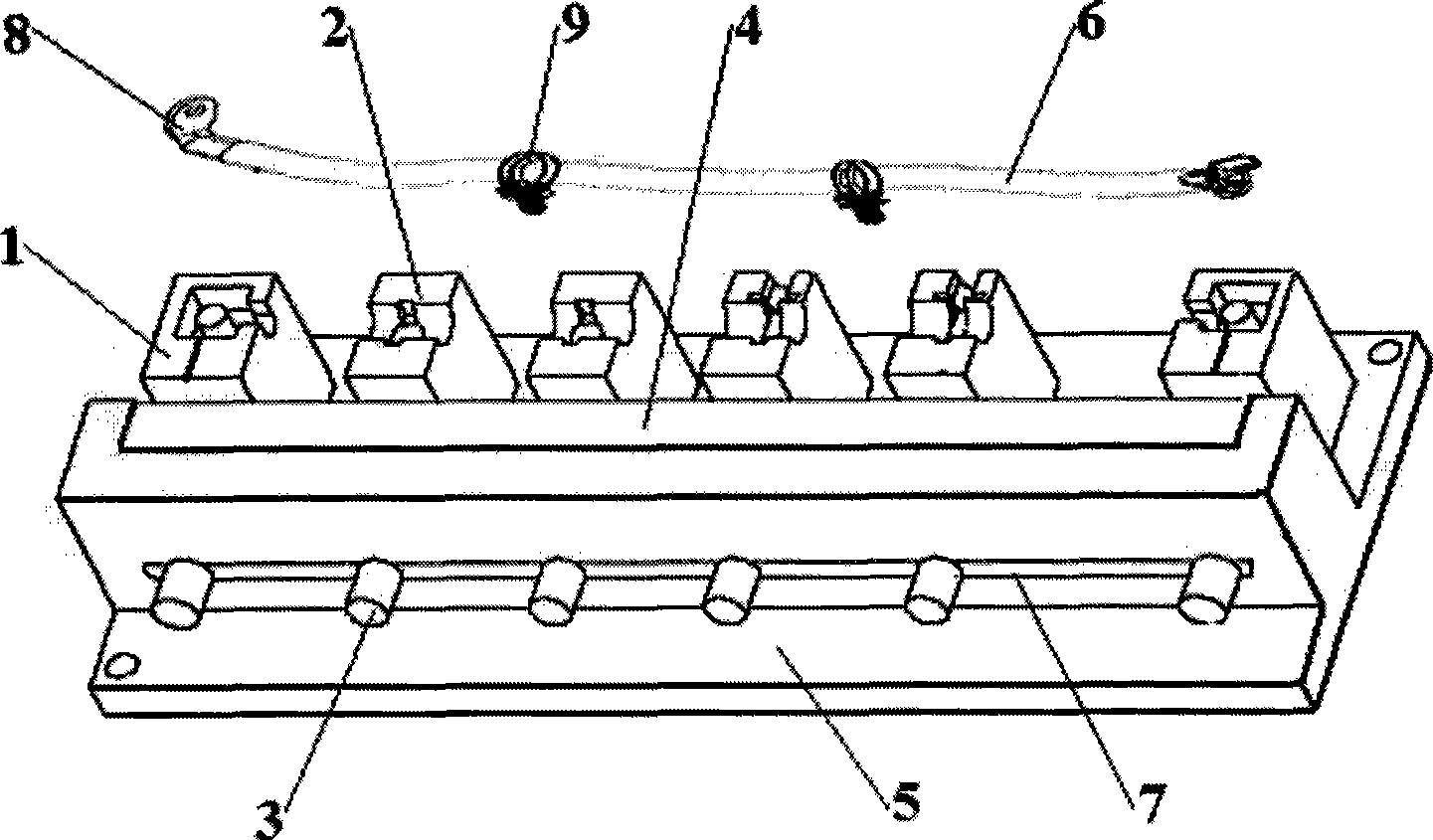

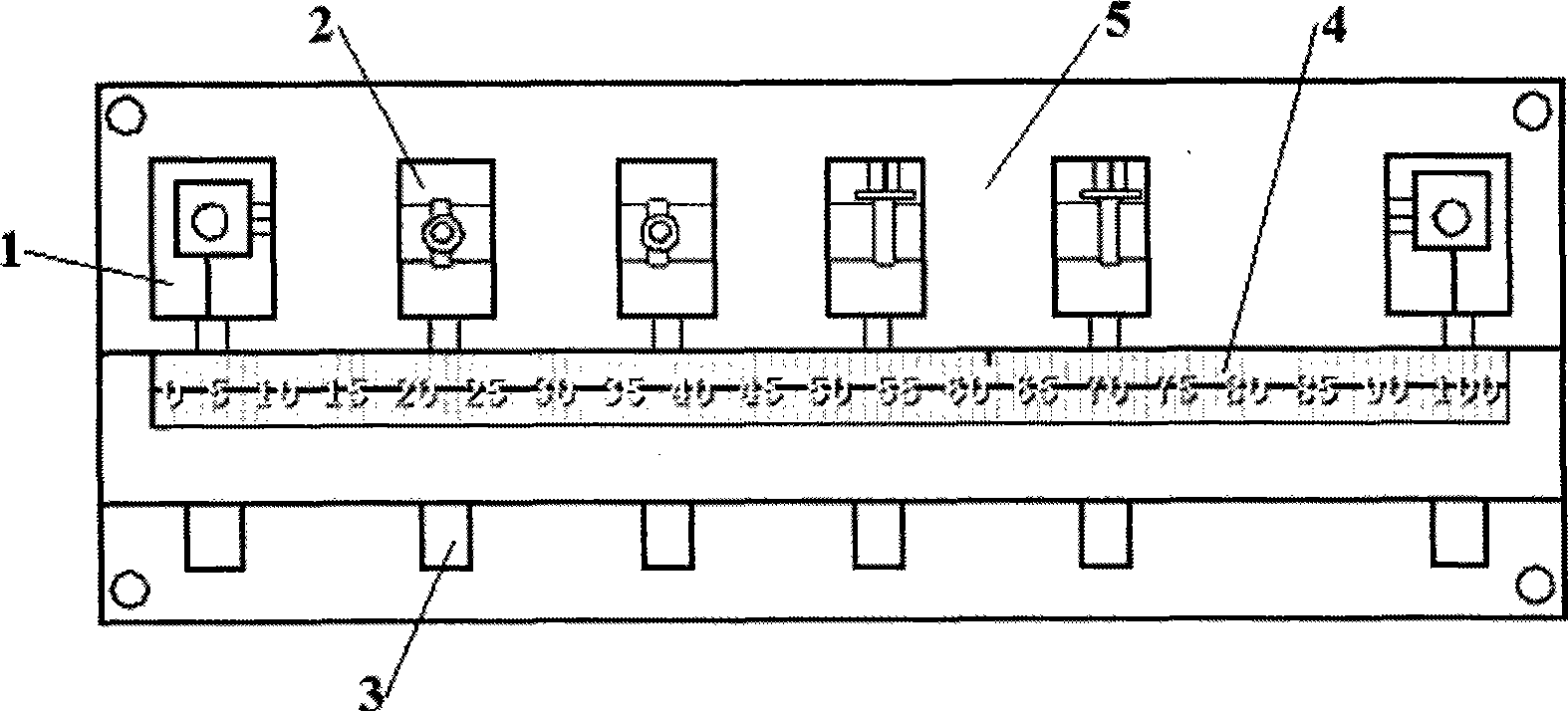

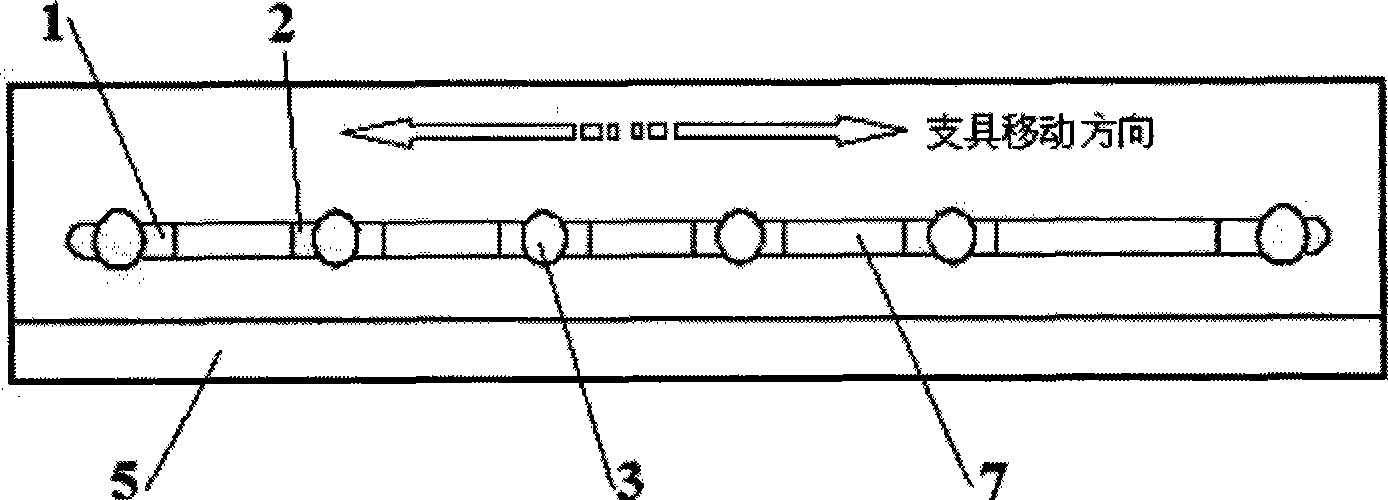

[0028] Such as figure 1 and image 3 As shown, the present invention sets a long groove-shaped moving slideway 7 on the tooling main body 5 along the direction in which the wire harness fixing support 1 and the accessory fixing support 2 are arranged, and the described fixing wire harness is used to fix the Each fastening bolt 3 of the support 1 and the accessory fixing support 2 passes through the moving slideway 7 to fasten the fixed wire harness fixing support 1 and the accessory fixing support 2 .

[0029] According to the specifications of the wire harness cable 6 product, select the corresponding wire harness fixing support 1 and accessory fixing support 2. According to the size requirements, adjust the position of the fastening bolt 3 on the moving slide 7, and lock the fastening bolt 3 after the position is correct. Tighten, so that both the wire harness fixing brace 1 and the accessory fixing brace 2 can obtain correct and reliable positions, and the positions can be...

Embodiment 2

[0032] Such as figure 1 and figure 2 As shown, the present invention sets a positioning scale 4 engraved with a length dimension on the tooling main body 5 along the direction in which the wire harness fixing bracket 1 and the accessory fixing bracket 2 are arranged, and is fixed on the tooling main body 5; the edge marked with the scale of the positioning scale 4 is in contact with the wire harness fixing support 1 and the accessory fixing support 2.

[0033] The wire harness fixing support 1 and the accessory fixing support 2 can measure accurate data through the positioning scale 4, and then use the fastening bolt 3 to fasten it, so as to ensure the stability and singleness of the product and improve the efficiency.

Embodiment 3

[0035] The operation method of the assembly tooling of the automobile wiring harness product according to the present invention is carried out in the following manner:

[0036] a) According to the specifications of the wire harness product, select the corresponding wire harness fixing bracket 1 and accessory fixing bracket 2, adjust the position of each bracket according to the size requirements, determine the correct position through the positioning scale 4, lock it with the fastening bolt 3, and Adjust the position at any time according to the operation situation;

[0037] b) After the position of the brace is adjusted, first place the wire harness accessory 9 on the accessory fixing bracket 2 for accurate positioning, then place the semi-finished wire harness cable 6 on the main body 5 of the tooling, and use the wire harness fixing bracket 1 to fix the wire harness cable 6 position;

[0038] c) After the wiring harness cable 6 and each support are positioned, install the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com