Furnace front coal head-drawing method for circulating fluid bed boiler

A technology of circulating fluidized bed and coal in front of the furnace, which is applied in the field of coal pyrolysis, can solve the problems of not being very applicable, and achieve the effect of making full use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

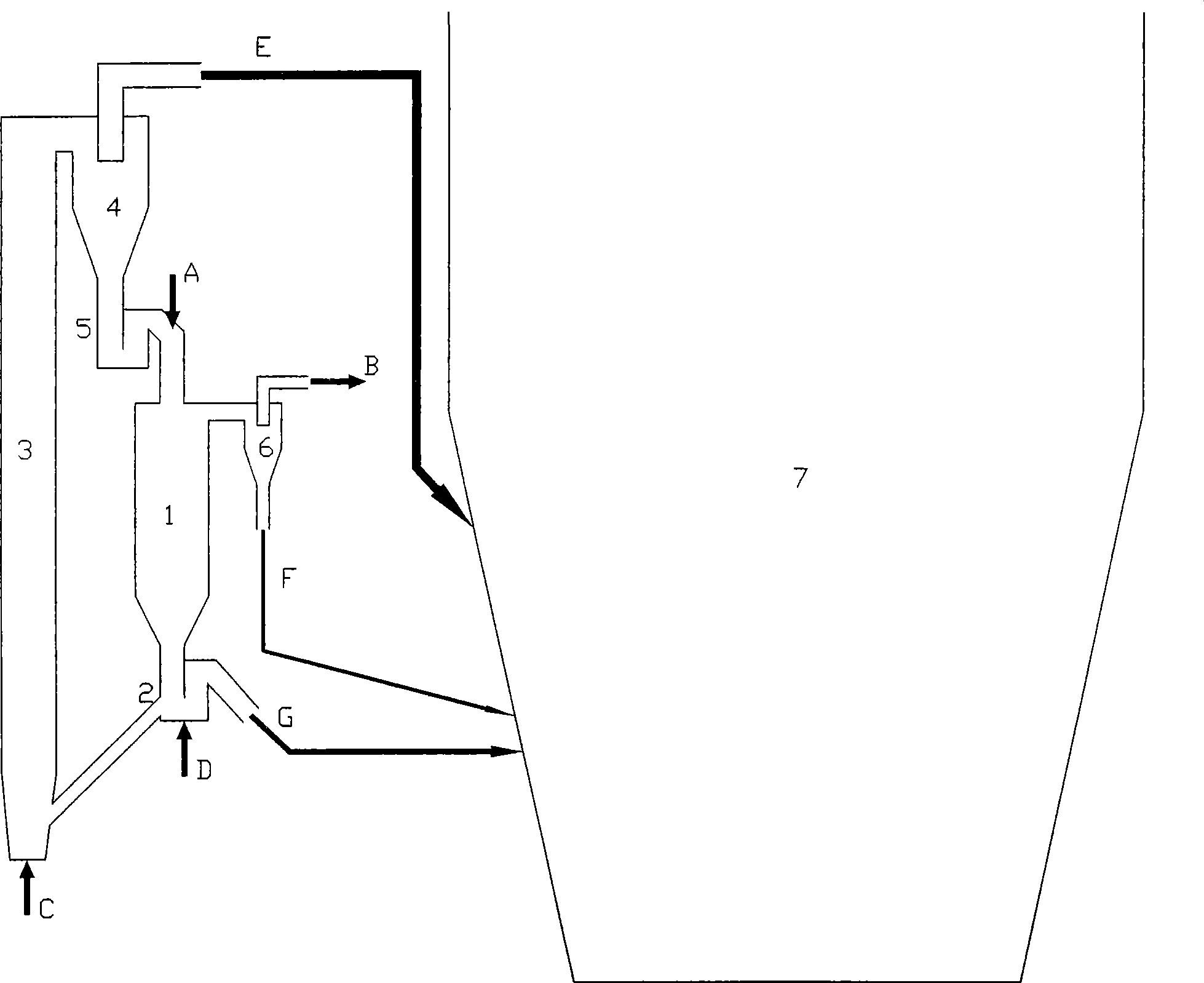

[0029] A coal topping device is installed in front of the circulating fluidized bed boiler, and all the boiler feed coal A is first put into the coal topping pyrolysis chamber 1 for pyrolysis reaction, and then sent to the circulating fluidized bed boiler furnace 7 for combustion.

[0030] Coal A with a particle size of 0-8mm is added from the upper part of the coal topping pyrolysis chamber 1, and the pyrolysis reaction is carried out to produce semi-coke G and pyrolysis gas B containing tar, which is discharged from the upper part of the pyrolysis chamber 1, finely The fine powder F separated from the pyrolysis gas B by the powder separator 6 is sent to the hearth 7 of the circulating fluidized bed boiler; the semi-coke G is discharged from the bottom of the pyrolysis chamber 1, and most of the semi-coke G is sent into the bottom feeder 2 The lower part of the circulating fluidized bed boiler hearth 7 is used as boiler coal feed, and a small part of semi-coke G is sent into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com