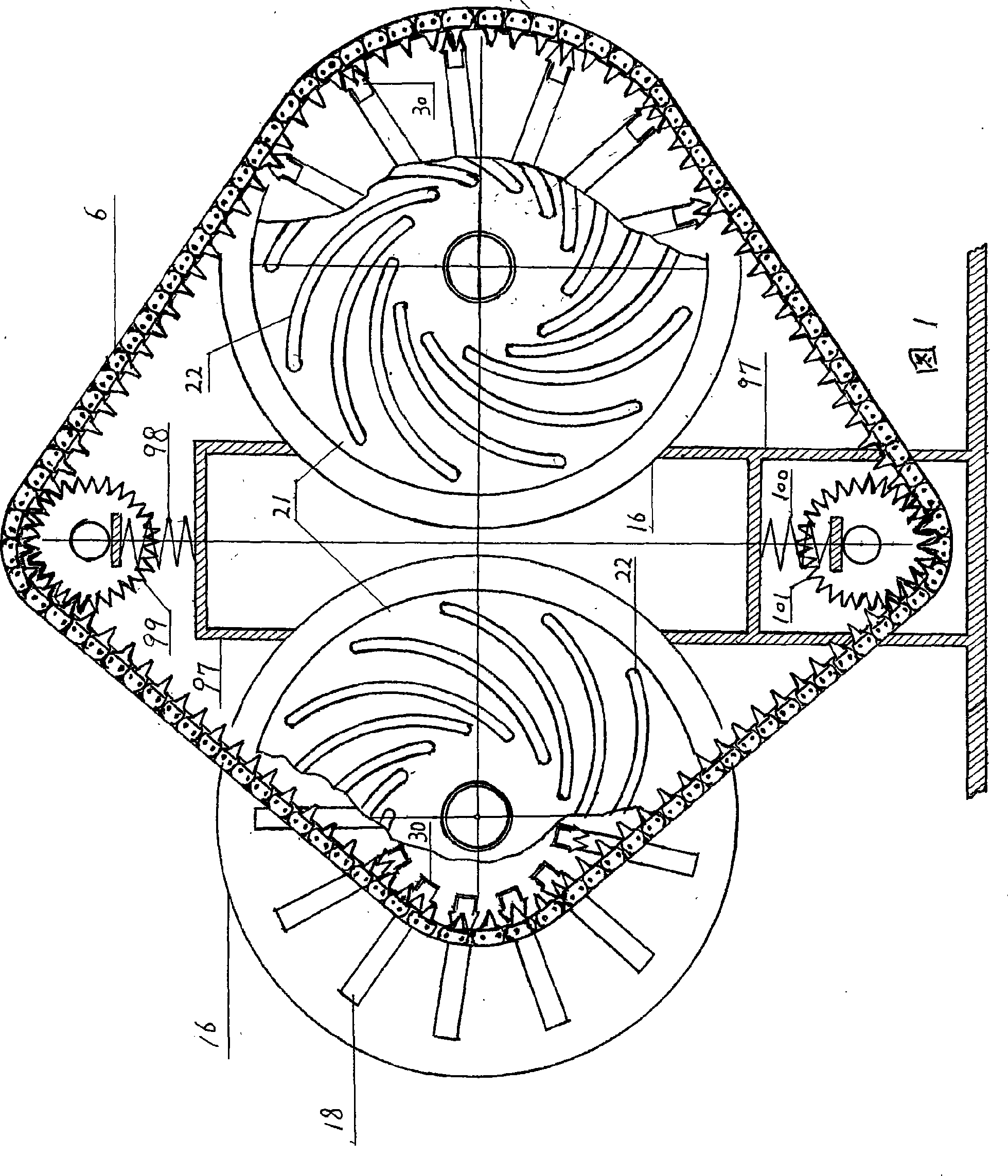

Gear engaging drive stepless speed changer

A continuously variable transmission, tooth meshing technology, applied in the direction of transmission chain, transmission, transmission control, etc., can solve the problems of short life, increased power consumption, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

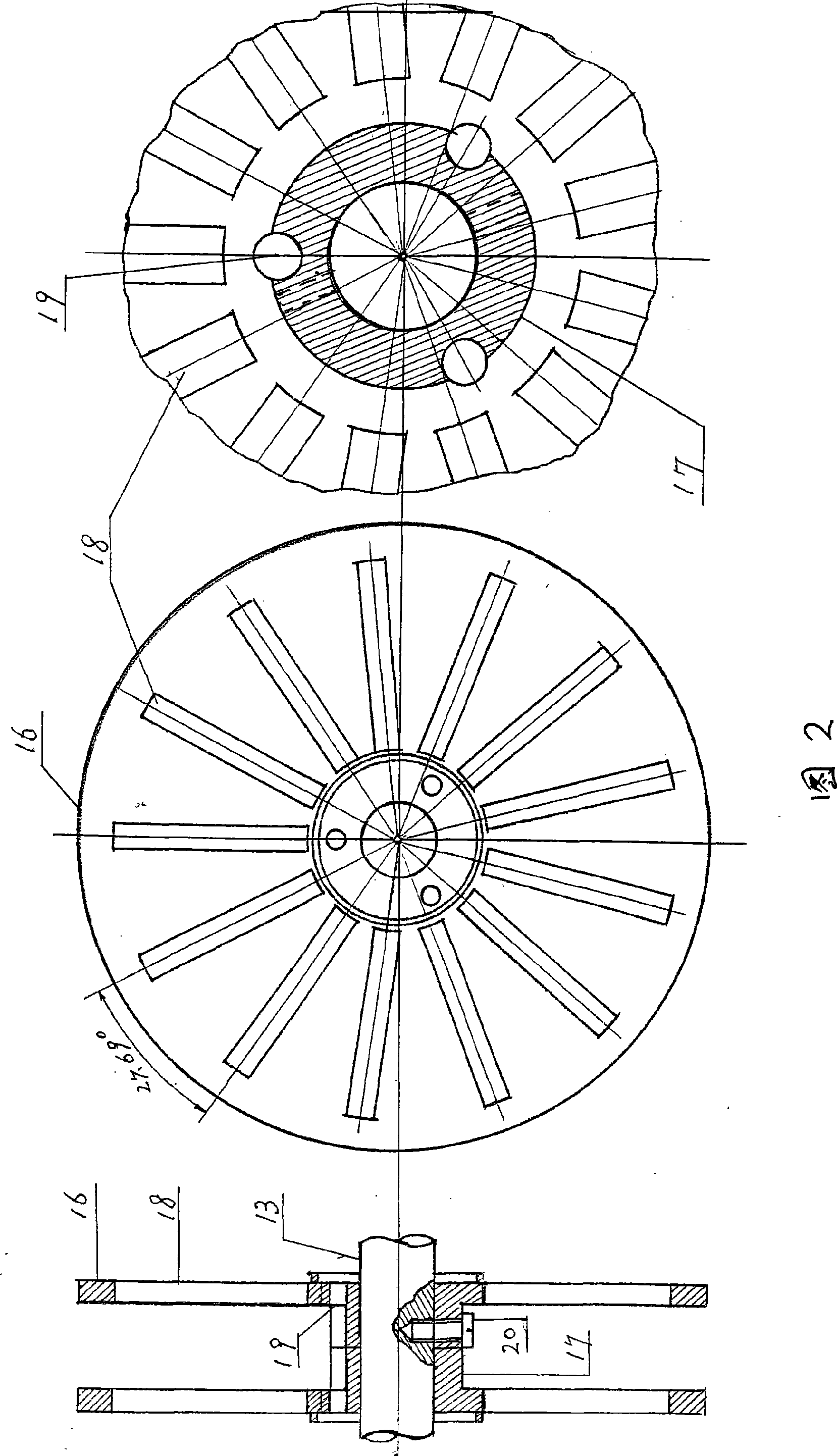

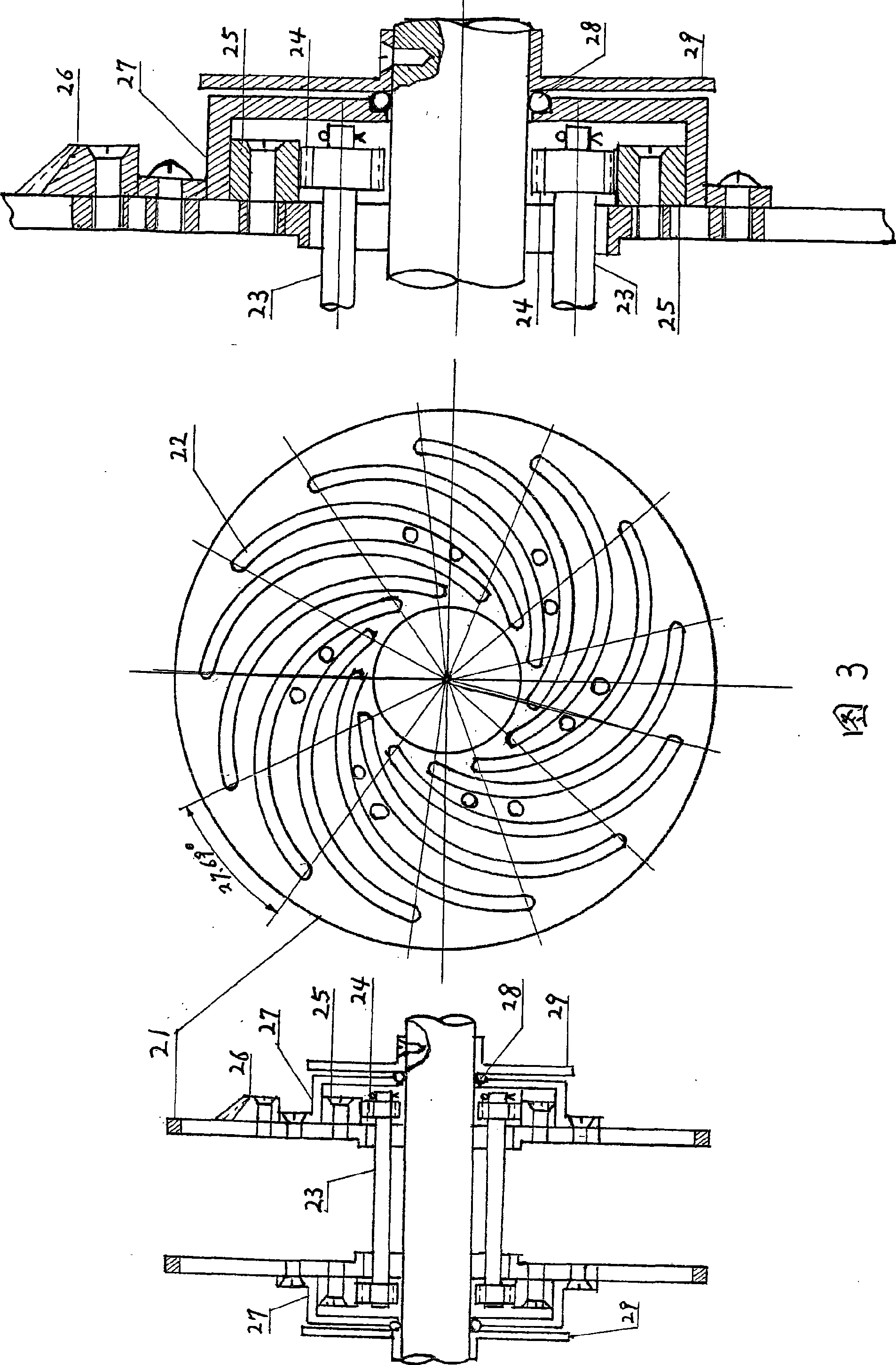

[0014] The installation structure of active and driven expansion and contraction gears is that the wheel hub 17 of the linear groove disc 21 on the shaft 13 is fixedly installed with screws 20 or with keys, and another same linear groove disc is fixedly installed on its corresponding surface. Shaped protruding portion, on its two linear groove discs, 4 or 4 or more equally distributed linear grooves 18 are symmetrically arranged respectively, and its length is long when the speed change ratio is large, and hour is short, and movable teeth 30 are placed on its two linear grooves. The tooth arm 33 and the tooth arm on the other side, the outer two sides of the linear groove disc are respectively equipped with arc groove discs 21. The number and distribution angle of the arc grooves 22 of the two arc groove discs are the same as the linear grooves of the straight groove discs. The number is the same as the angle, and the length of its arc groove is made by the longest arc groove c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com