Numerical control non-mould molding equipment of sheet metal

A metal sheet and moldless forming technology, applied in metal processing equipment, etc., can solve the problems of difficult control of manufacturing precision, high cost, complex mold and process, etc., and achieve the effect of high precision and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific content of the present invention will be further described below in conjunction with the accompanying drawings.

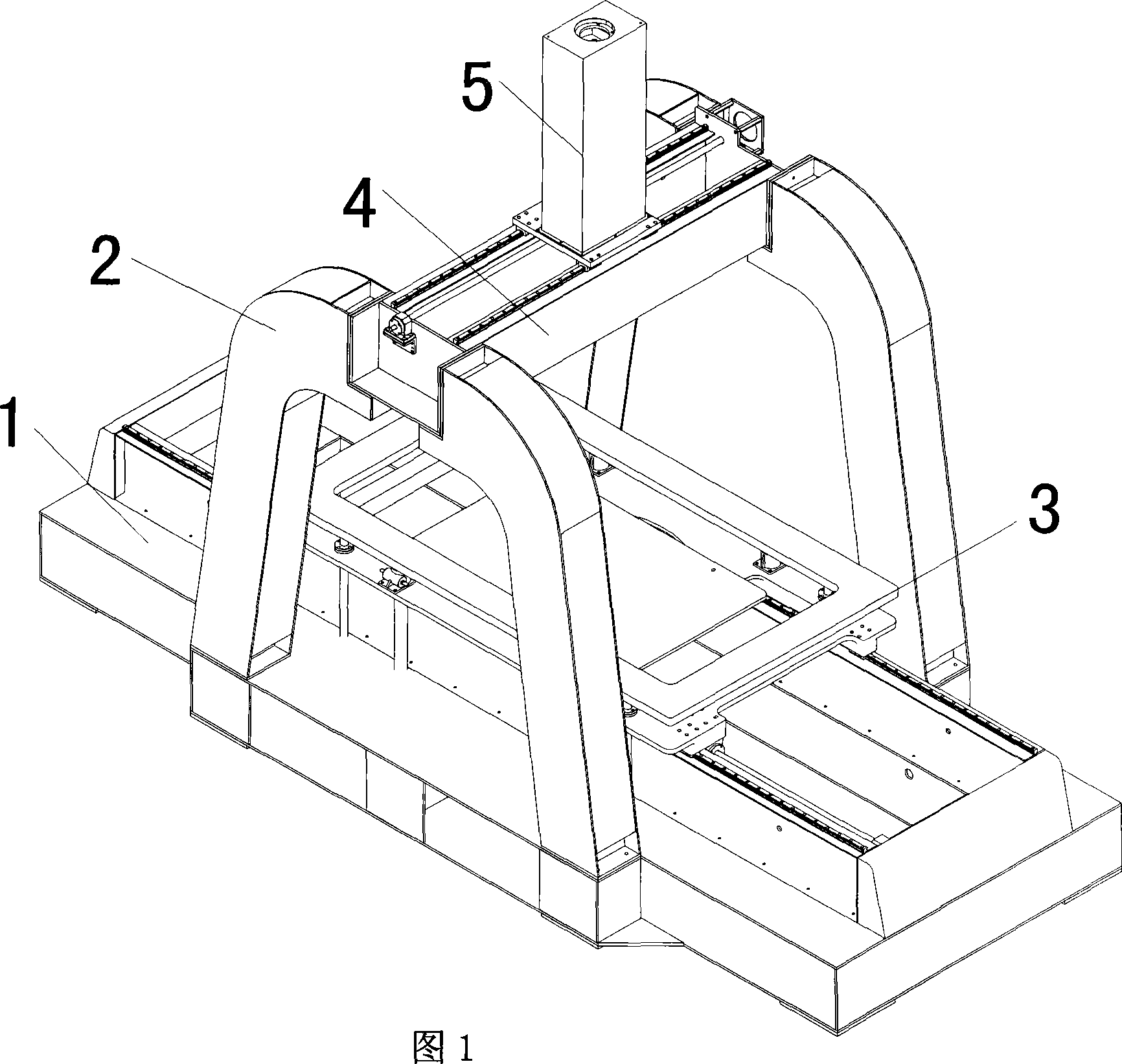

[0016] Metal plate CNC moldless forming equipment, including a base 1, two pairs of columns 2 installed on the left and right sides of the base 1, the column 2 is composed of two column feet and a top beam, and the base 1 is equipped with X-axis guide rails 102, the X-axis guide rail 102 is provided with an X-axis platform 3 that can move on it, the top beams of the two pairs of columns 2 are provided with a Y-axis platform 4, and the Y-axis platform 4 is provided with a Y-axis guide rail 401 , the Y-axis guide rail 401 is provided with a Z-axis spindle 5 .

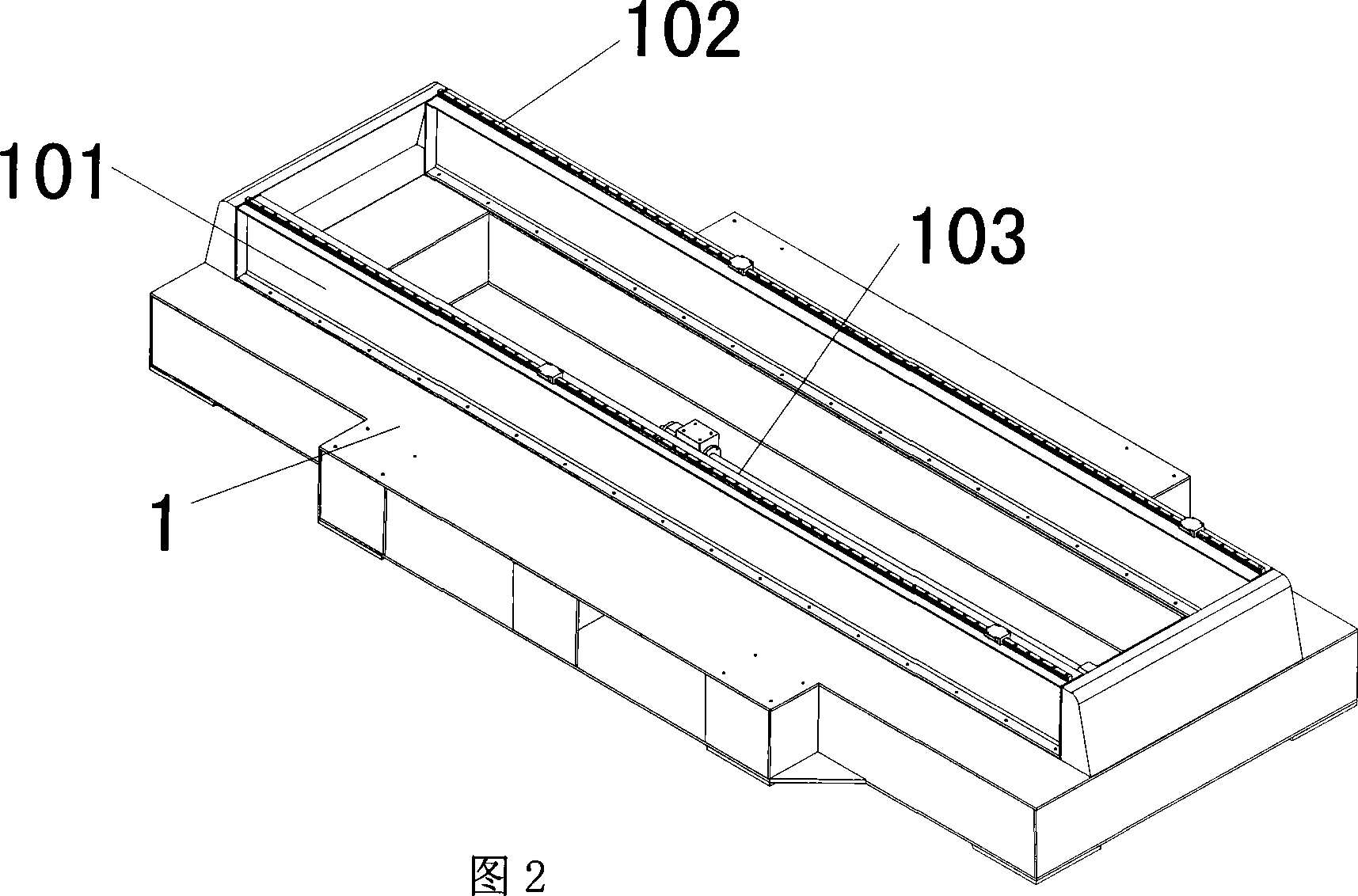

[0017] There are two X-axis guide rails 102, which are fixed on the base 1 through H-shaped steel 101. Two inner sides of the X-axis guide rail 102 are provided with X-axis screw rods 103 .

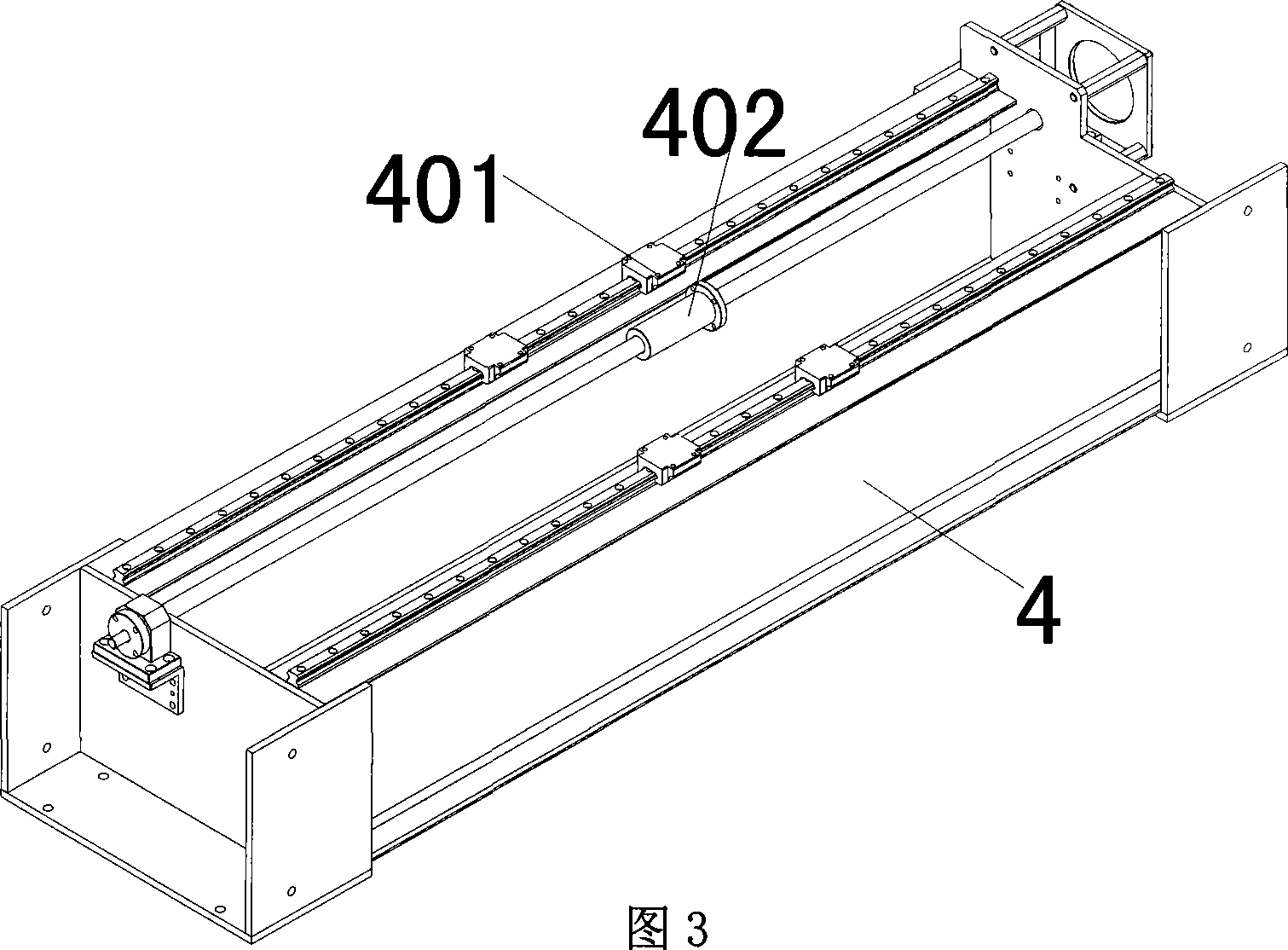

[0018] There are two Y-axis guide rails 401, which are fixedly connected to both sides of the Y-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com