Resin composition and multilayer structure body using the same

A technology of resin composition and multi-layer structure, which is applied in synthetic resin layered products, applications, household appliances, etc., can solve the problems of reduced barrier performance, poor appearance, voids, etc., and achieves excellent gas barrier properties and good resistance. pinhole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

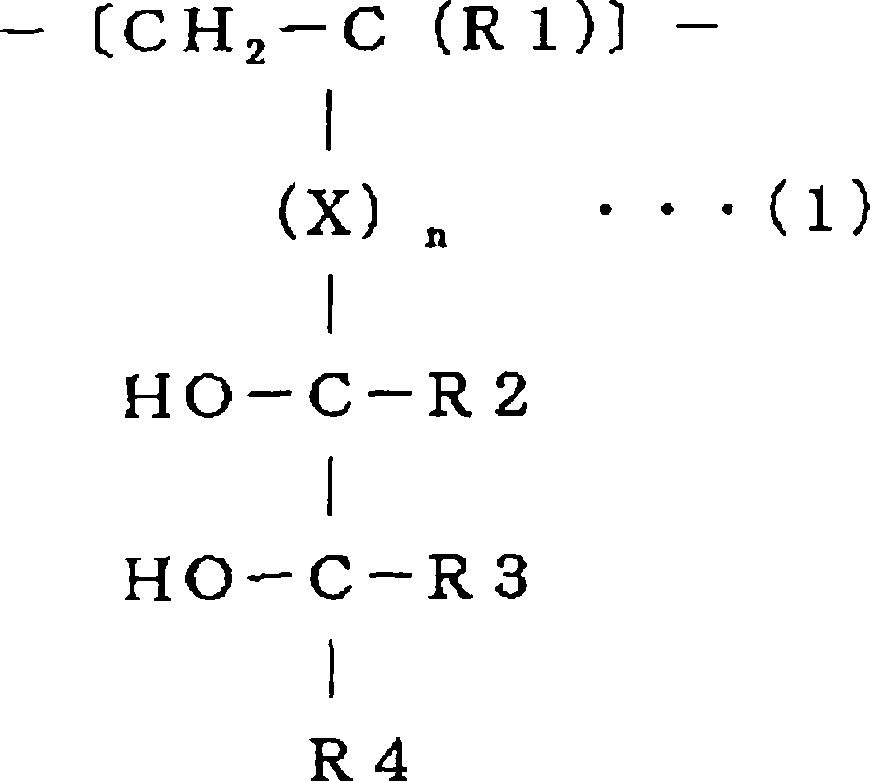

Method used

Image

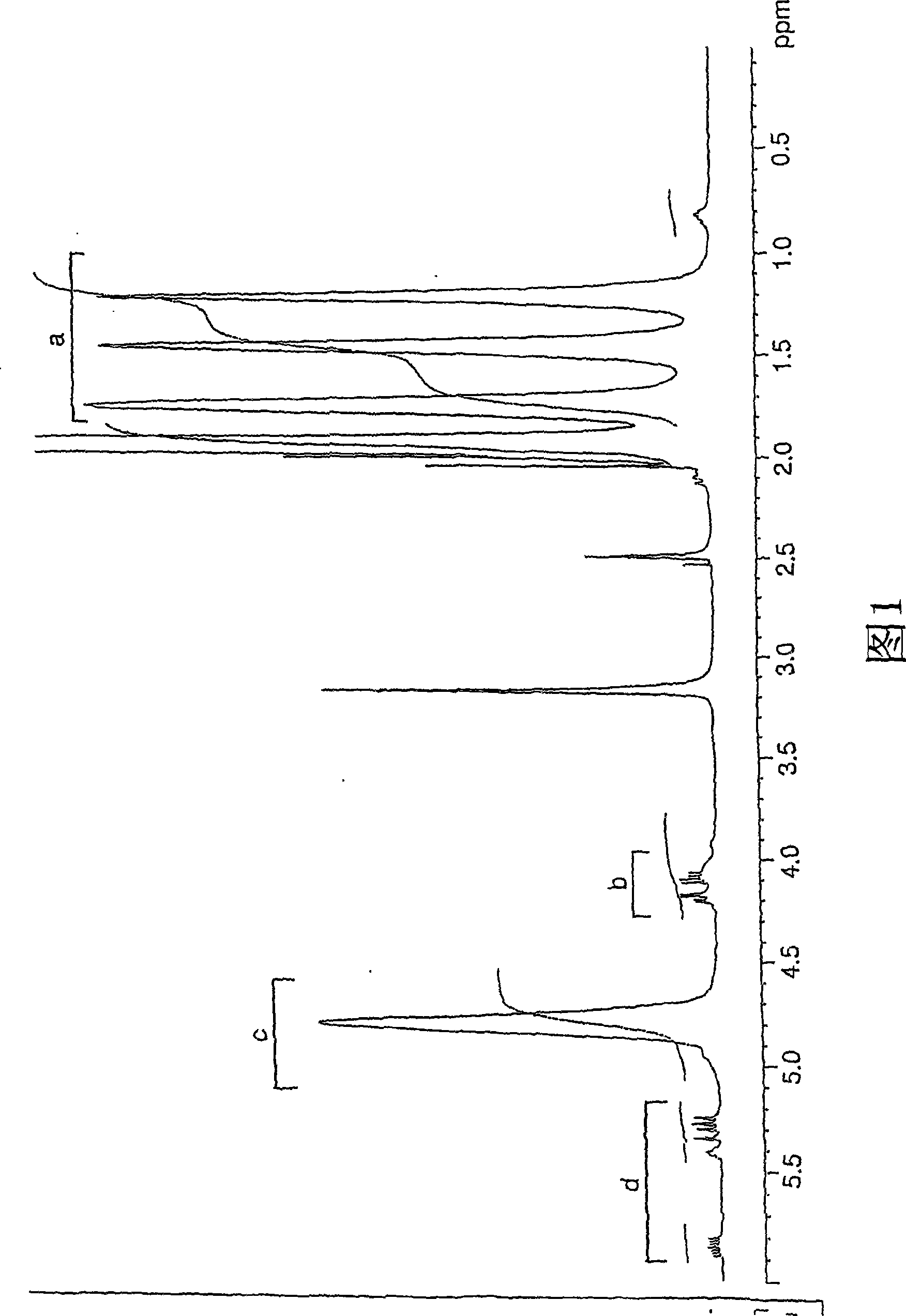

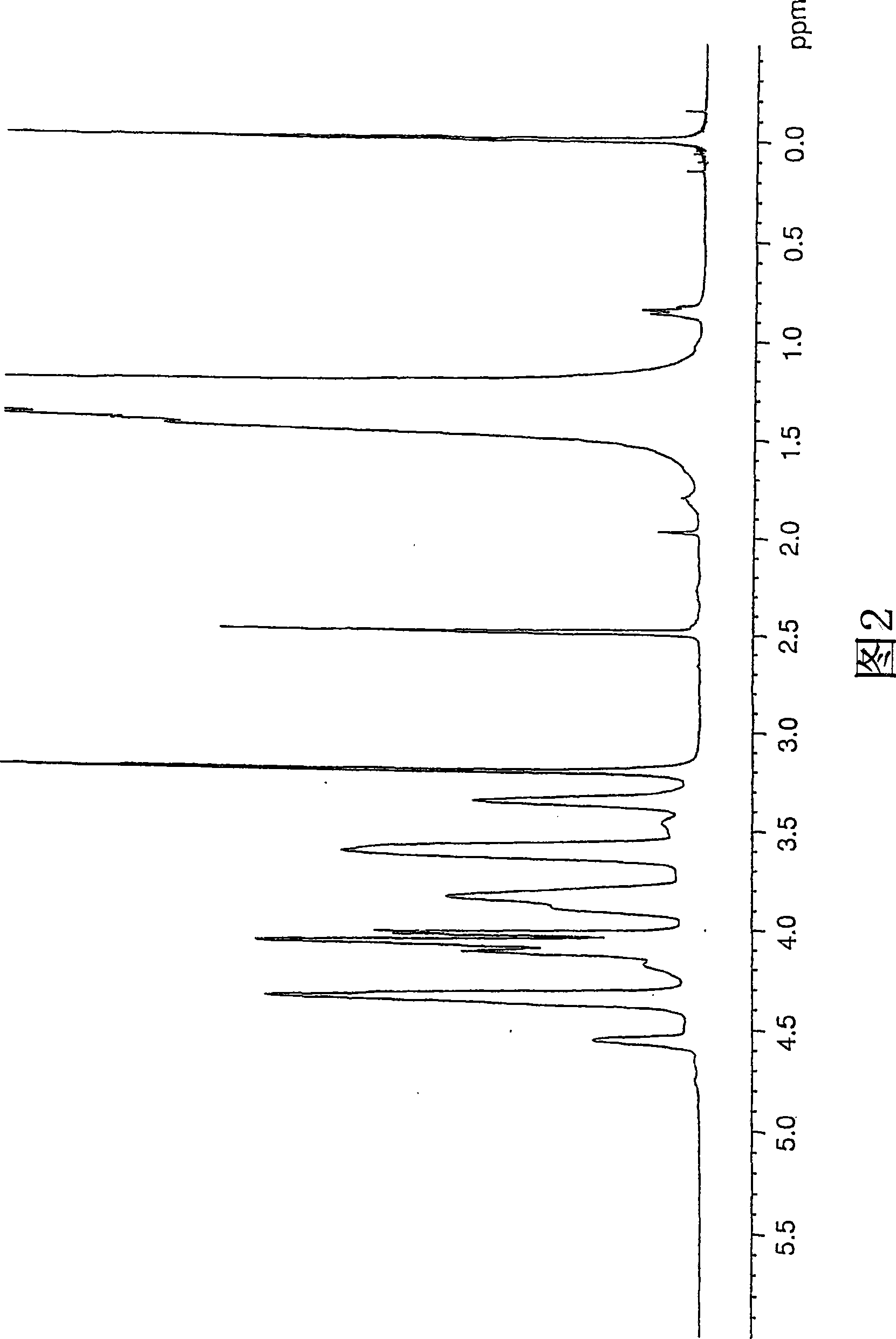

Examples

Embodiment 1

[0116] The EVOH composition (A1) obtained above and end-blocked nylon (B) [terminal carboxyl group content 20 μeq / g, terminal amino content 26 μeq / g] were supplied to a 30mmФ twin-screw extruder at a compounding weight ratio of 85:15 , melted and mixed at 240° C. to obtain pellets of the target resin composition.

[0117] The pellets (resin composition) (a) obtained above, nylon-6 ["NOVAMID 1022-1" manufactured by Mitsubishi Engineering Plastics Corporation] (b), polypropylene ["FL6CK" manufactured by Japan Poly Chem Corporation] (c) and Adhesive resin [Mitsui Chemicals "ADMER QFS00", maleic anhydride-modified polypropylene] (d) was supplied to a feed block type co-extrusion multilayer film forming machine (manufactured by GUNZE Sangyo Co., Ltd.), and formed into a A laminate (multilayer film) of a layer structure of (b) / (a) / (d) / (c)=20 / 20 / 10 / 80 (μm; thickness).

[0118] The obtained laminate was evaluated as follows regarding appearance, gas barrier properties, and pinhole re...

Embodiment 2

[0129] Except having used the EVOH composition (A2) instead of the EVOH composition (A1) in Example 1, the resin composition was produced similarly, and the same evaluation was performed.

Embodiment 3

[0131]Except having used the EVOH composition (A3) instead of the EVOH composition (A1) in Example 1, the resin composition was produced similarly, and the same evaluation was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com