Electric connection structure of circuit board and circuit board with the same

A technology for circuit boards and conductive structures, which is applied in the directions of printed circuit components, electrically connected printed components, and printed circuits connected with non-printed electrical components, which can solve the problems of ineffective reduction, loss of decoupling of decoupling capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

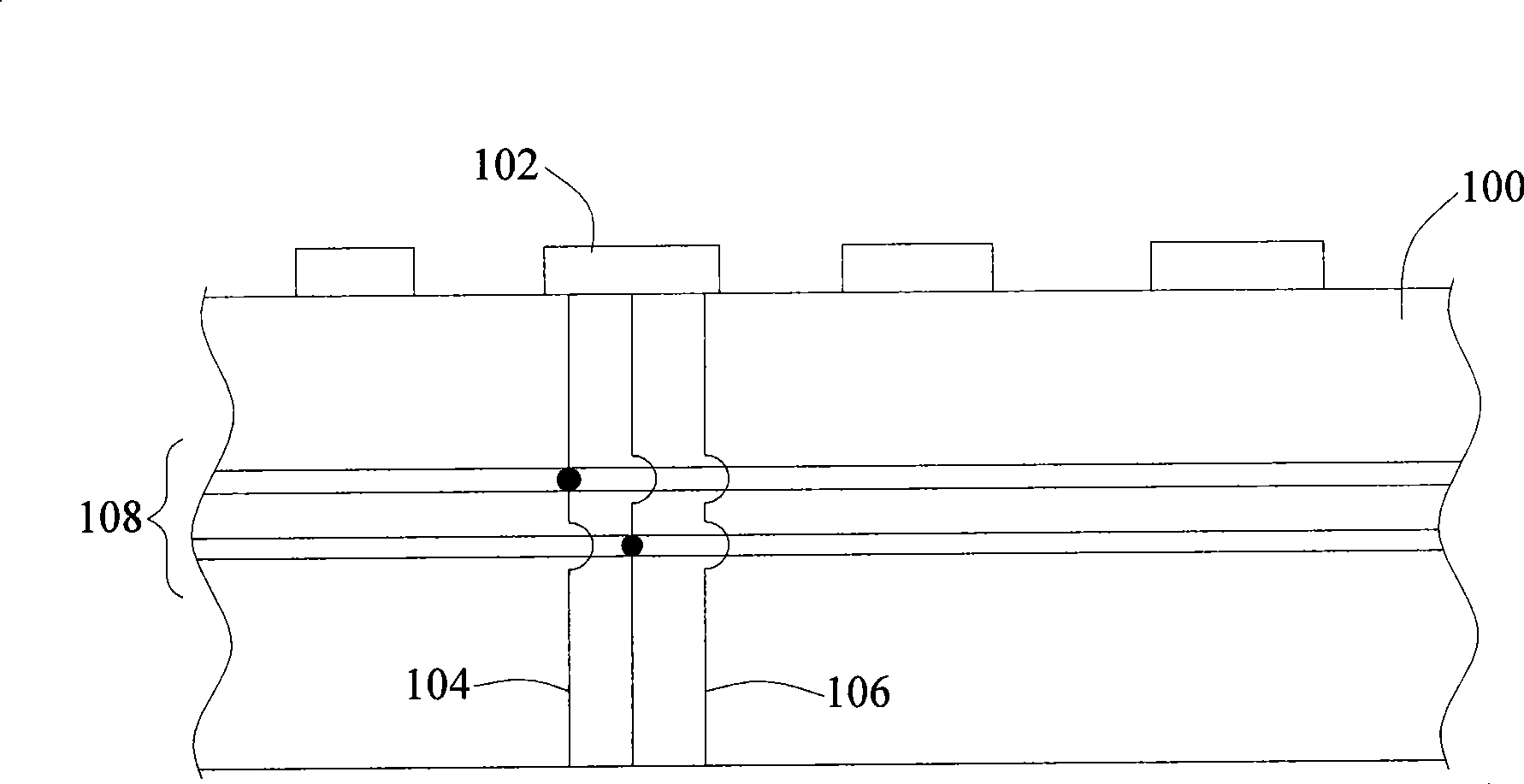

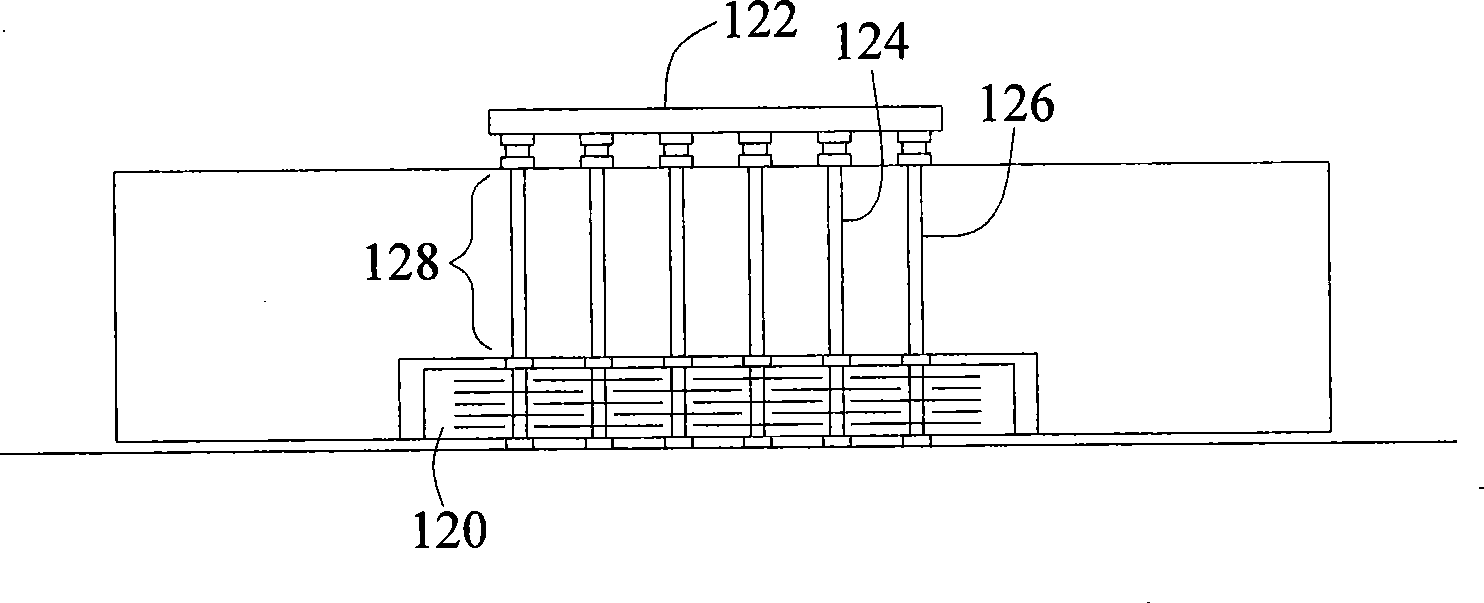

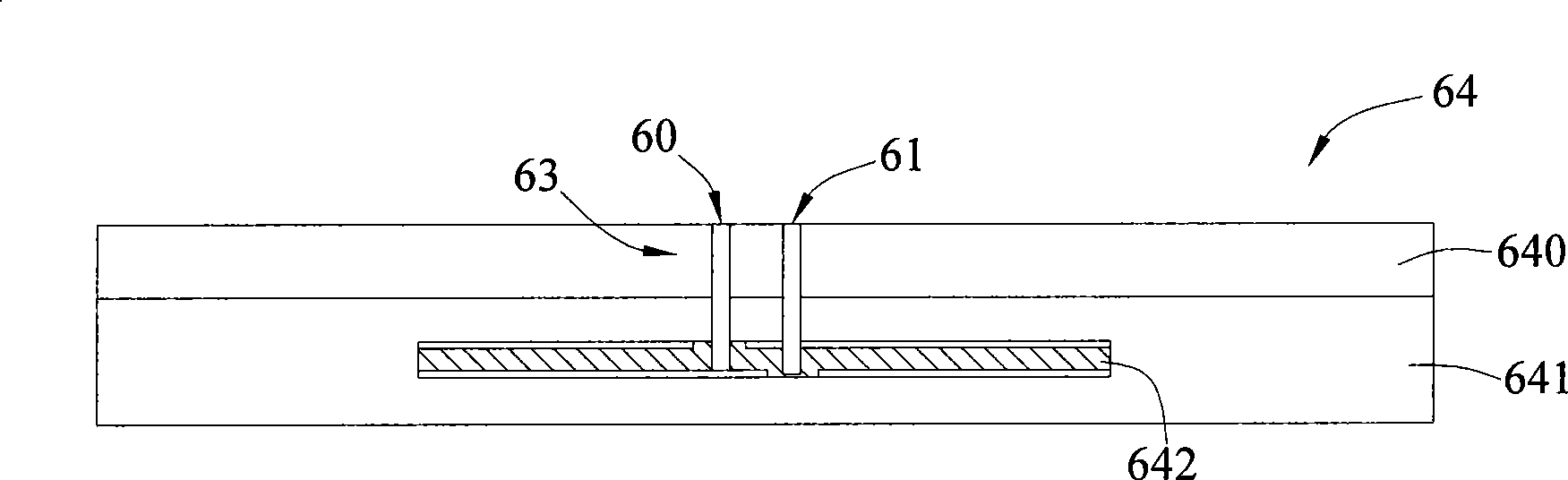

[0081] Please also refer to Figure 5 , Figure 6 and Fig. 7, which is a structural schematic diagram of the first embodiment of the electrical connection structure of the present invention, wherein Figure 6 is a three-dimensional structure diagram of the first embodiment, Figure 5 it's for Figure 6 , and FIG. 7 is a structural diagram of the first embodiment actually configured in the circuit board 300, and its representation is for the first embodiment in the Figure 5 The sectional view of position 7-7 in the center is expressed by taking a 90-degree section and turning the section area at a 90-degree angle to form a plane.

[0082] Please mainly match with Figure 7 Figure 5 and Figure 6 After reading, it can be seen from the figure that the electrical connection structure 200 of the first embodiment is to electrically connect at least one power contact 91 and at least one ground contact 92 of the electronic component 90 to the power plane 302 and the power plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com