Corrugated metal sheath inorganic mineral insulation cable and method for producing the same

A technology of metal sheath and inorganic minerals, applied in the direction of insulated cables, inorganic insulators, cable/conductor manufacturing, etc., can solve the problems of easy bending of wires and cables, achieve the effects of reducing property losses, easy installation, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

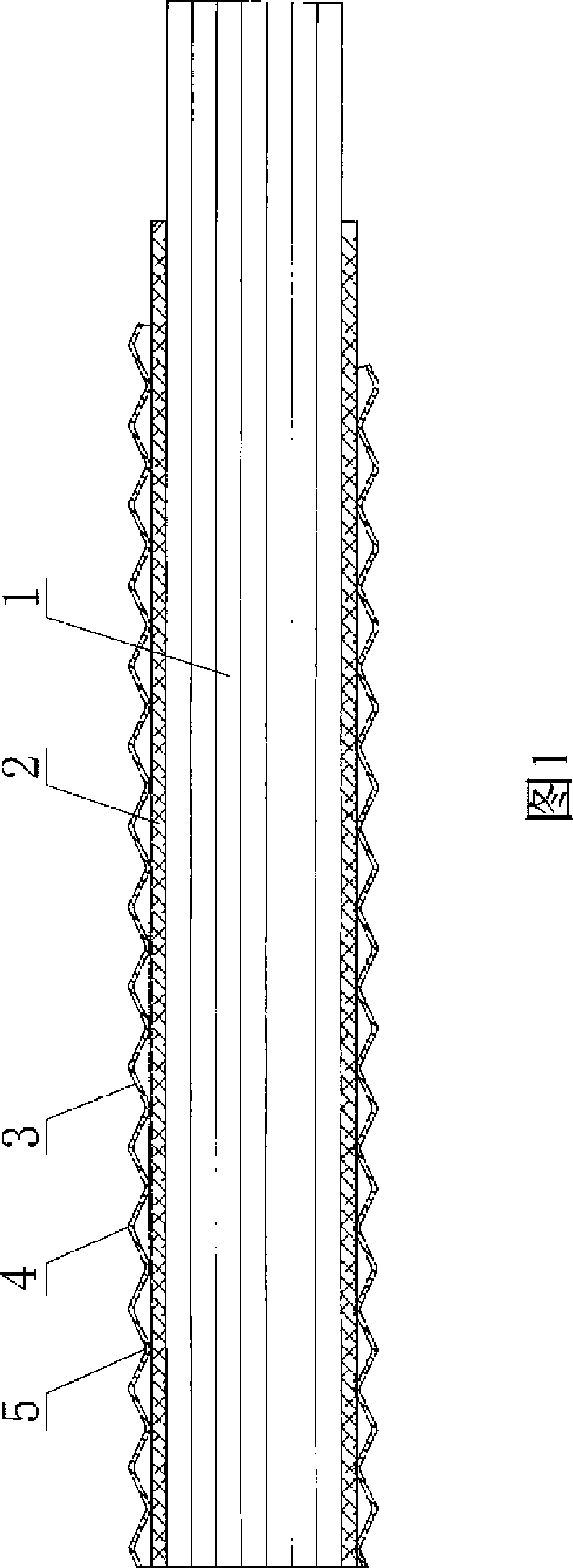

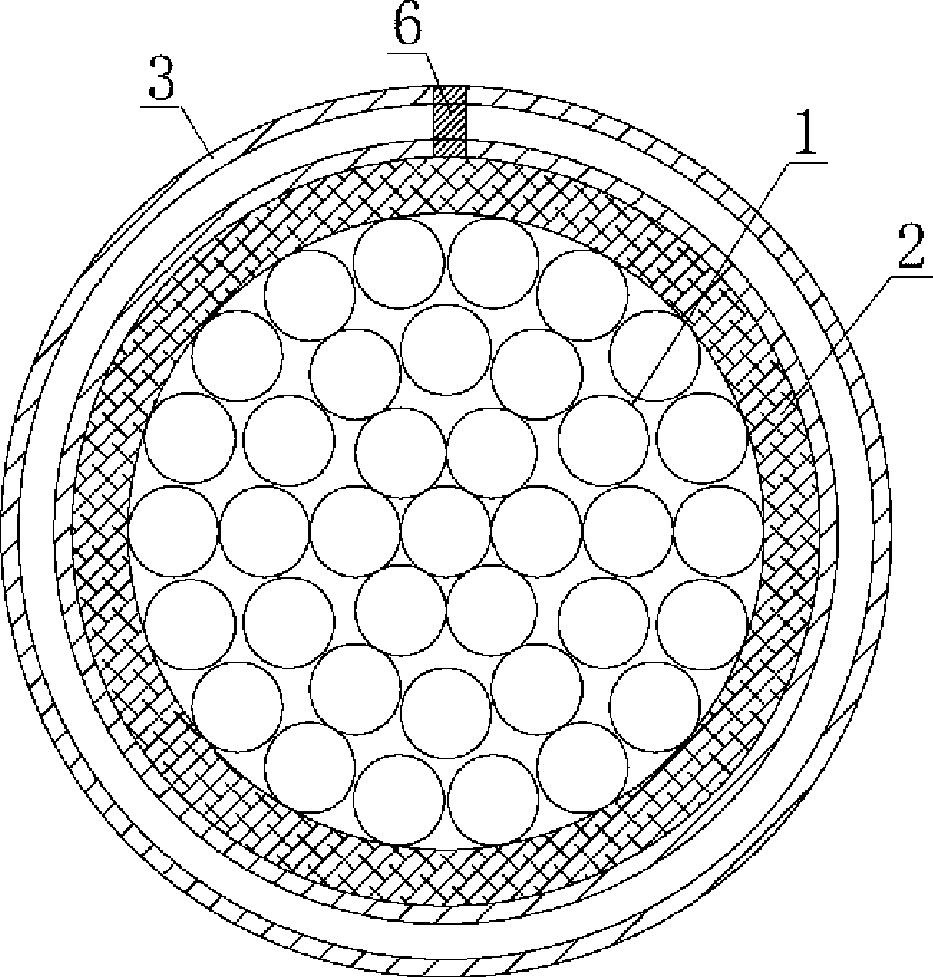

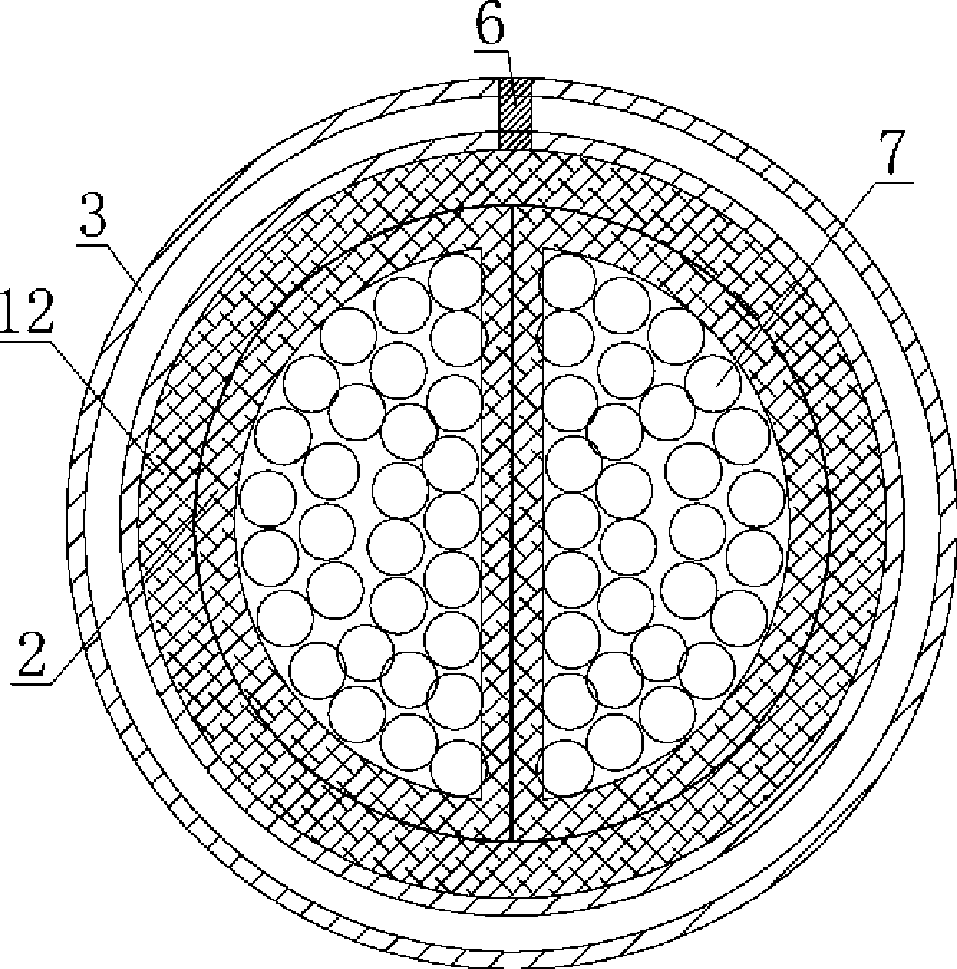

[0030] Embodiment referring to Fig. 1, figure 2 As shown, this corrugated metal sheathed inorganic mineral insulated cable is composed of an inner cable core, an insulating layer 2 wound outside the cable core and an outermost metal sheath 3. The cable core is composed of a bunch of The wire is twisted, the insulating layer 2 is an inorganic mineral insulating tape, the metal sheath 3 is a copper bellows, the corrugation of the copper bellows has an upper peak 4 and a lower valley 5, the length of the cable core, the insulating layer, and the copper bellows In order to be equivalent, the surface of the copper bellows has a weld 6 equal to its length along the axial direction. The above-mentioned cable core is a single-core cylindrical cable core 1, 6-8 layers of insulating layers 2 are wound outside the cable core, and the number of wires per core is 1 to 61.

[0031] The wires may be copper wires, copper alloy wires or lead wires. The length of the copper bellows can be fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com