Product structure modularization method and evaluation method for mechanical electronic product

A technology of product structure and mechatronics, applied in computer components, character and pattern recognition, instruments, etc., can solve problems such as difficulty in ensuring optimality, complex operation, and impact, and achieve the effect of convenient modular analysis and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

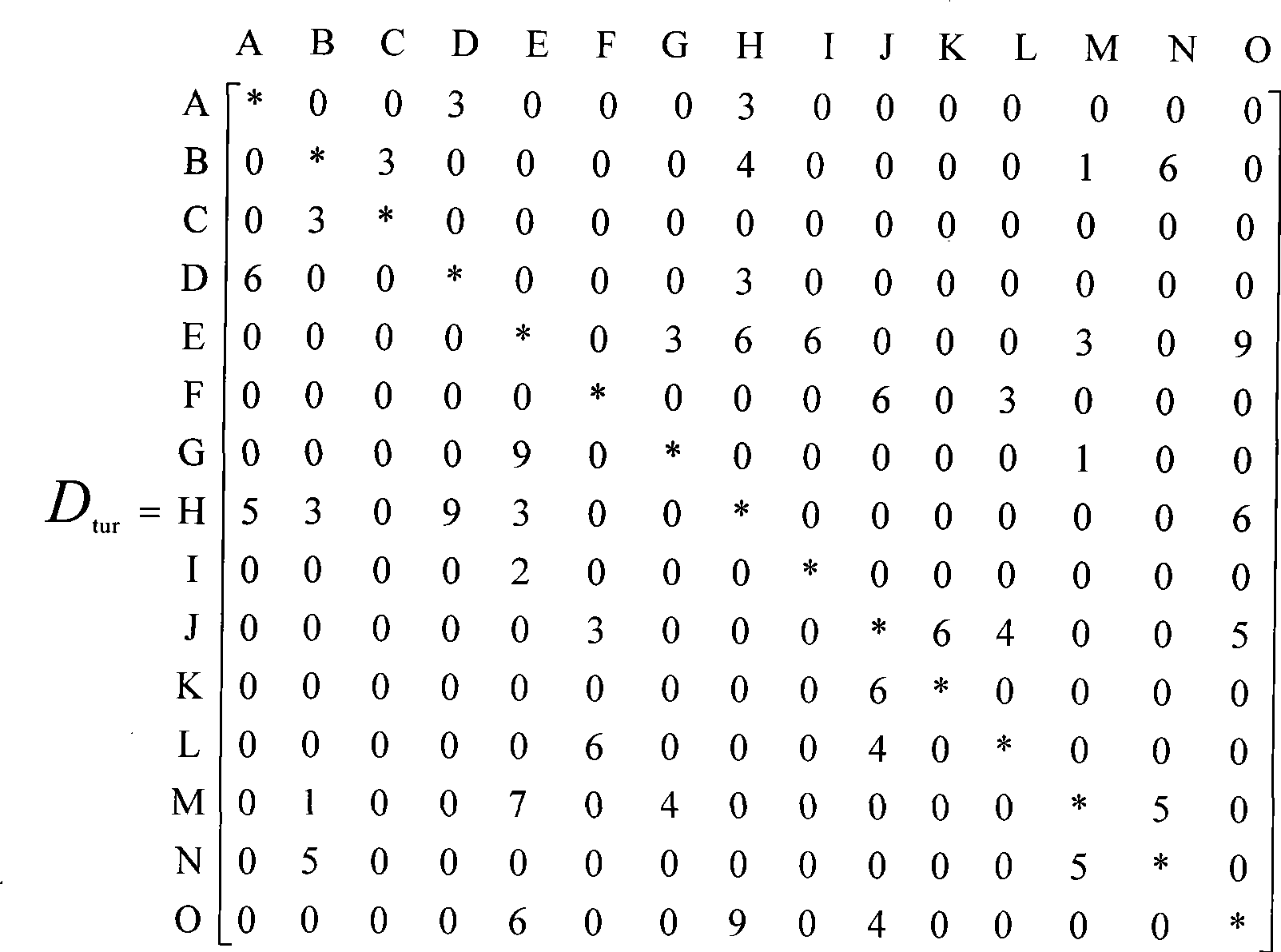

[0063] Taking a certain type of turbocharger as an example, after identification, the rank and column elements of the obtained DSM model are: turbine intake casing, turbine exhaust casing, bottom bracket, turbine nozzle ring, compressor impeller, bearing damper, diffuser Devices, turbine rotor blades, intake muffler filters, ball bearings, oil throwing pans, bearing housings, compressor outlet turbine shells, heat shields, and rotating shafts. The 15 row and column elements are respectively numbered as: A~O. Identify the relationship between the elements of each row and column, and reduce the dimension of the obtained four-vector model, you can get the single-vector, numerical product structure model matrix D tur like figure 1 shown.

[0064] pair matrix D tur The DSM model of a certain type of axial flow turbocharger shown is divided into modules based on row and column transformation, and there are many schemes, the following are three typical ones.

[0065] Module schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com