Analysis method used for in-mold decoration injection molding

A technology of injection molding and in-mold decoration, applied in the field of analysis, can solve problems such as unreasonable assumptions, inability to meet user needs, etc., to reduce costs, improve analysis accuracy, and shorten development time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

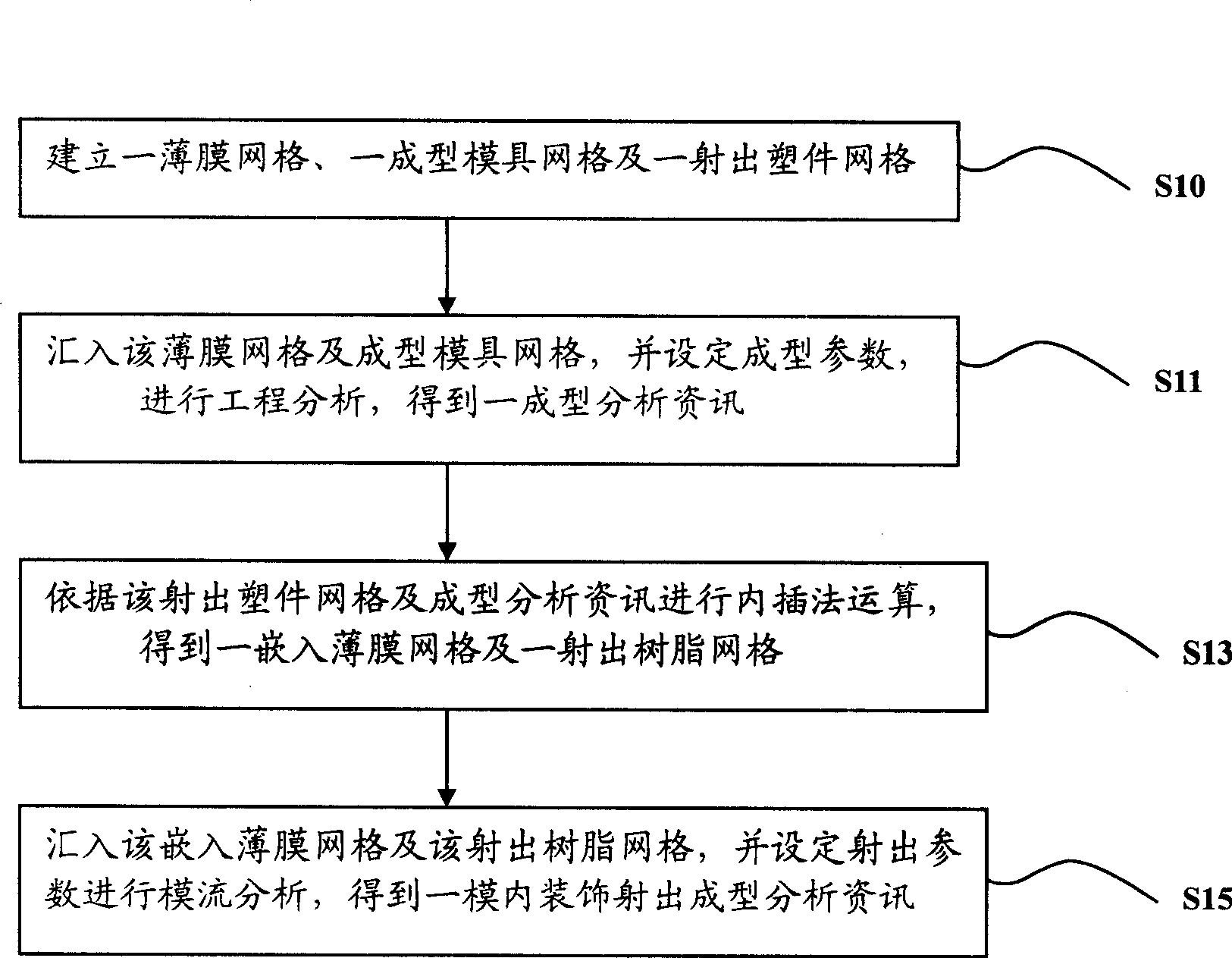

[0071] This embodiment is the implementation process of actually using the engineering analysis method of the present invention, please refer to figure 1 , execute step S10 first, establish a film grid 10, a forming mold grid 12 and a plastic part grid 14, the above-mentioned film grid 10 is to utilize T-SIM software to establish, please refer to Fig. 2A, it is the present embodiment Schematic diagram of the film grid, and the size of the film grid in this embodiment is 170mm X 100mm, and the thickness is 0.175mm.

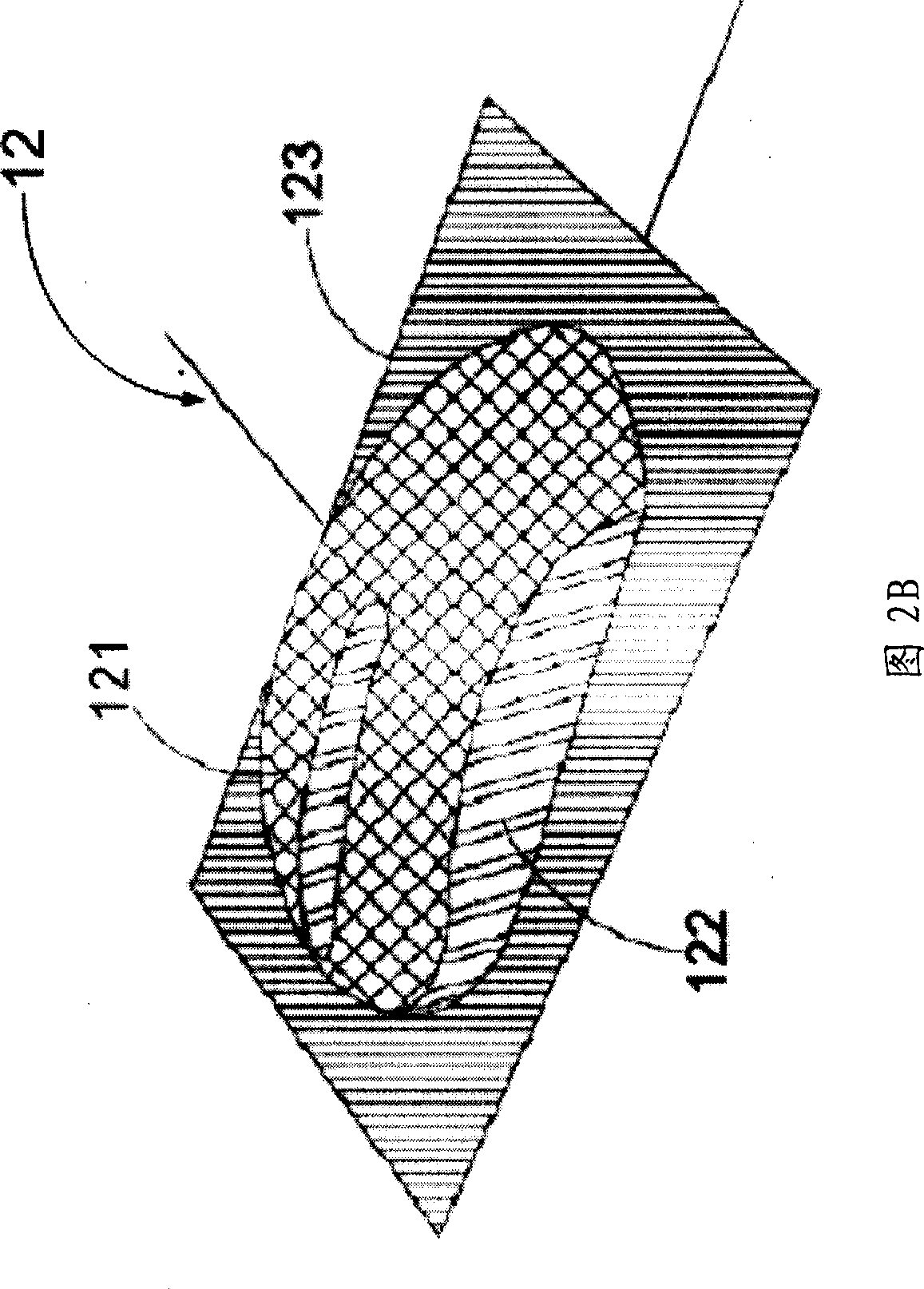

[0072] The forming mold grid 12 of this embodiment requires good grid quality, and is established using Moldex3D-Mesh software, and controls the appropriate number and quality of grids. The format of the forming mold grid 12 is selected from rapid manufacturing (STL) format) for T-SIM software to read, the forming mold grid 12 is shown in Figure 2B, the area marked 121 is the cut and formed film area (formable film area), and the area marked 122 is In the trimming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com