Three-freedom double-layer oil film type spherical hinge

A degree of freedom and double-layer technology, applied in the field of mechanical transmission, can solve the problems such as the difficulty of static debugging of the oil film, achieve the effect of improving the sealing effect, improving the connection stiffness and service life, and reducing the spherical rotational moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

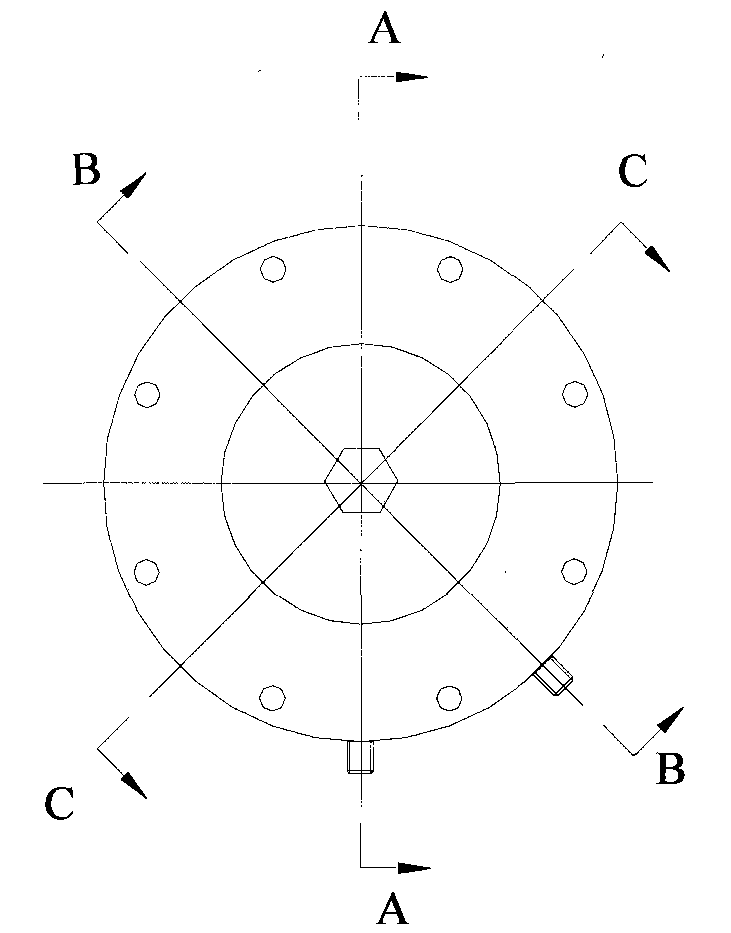

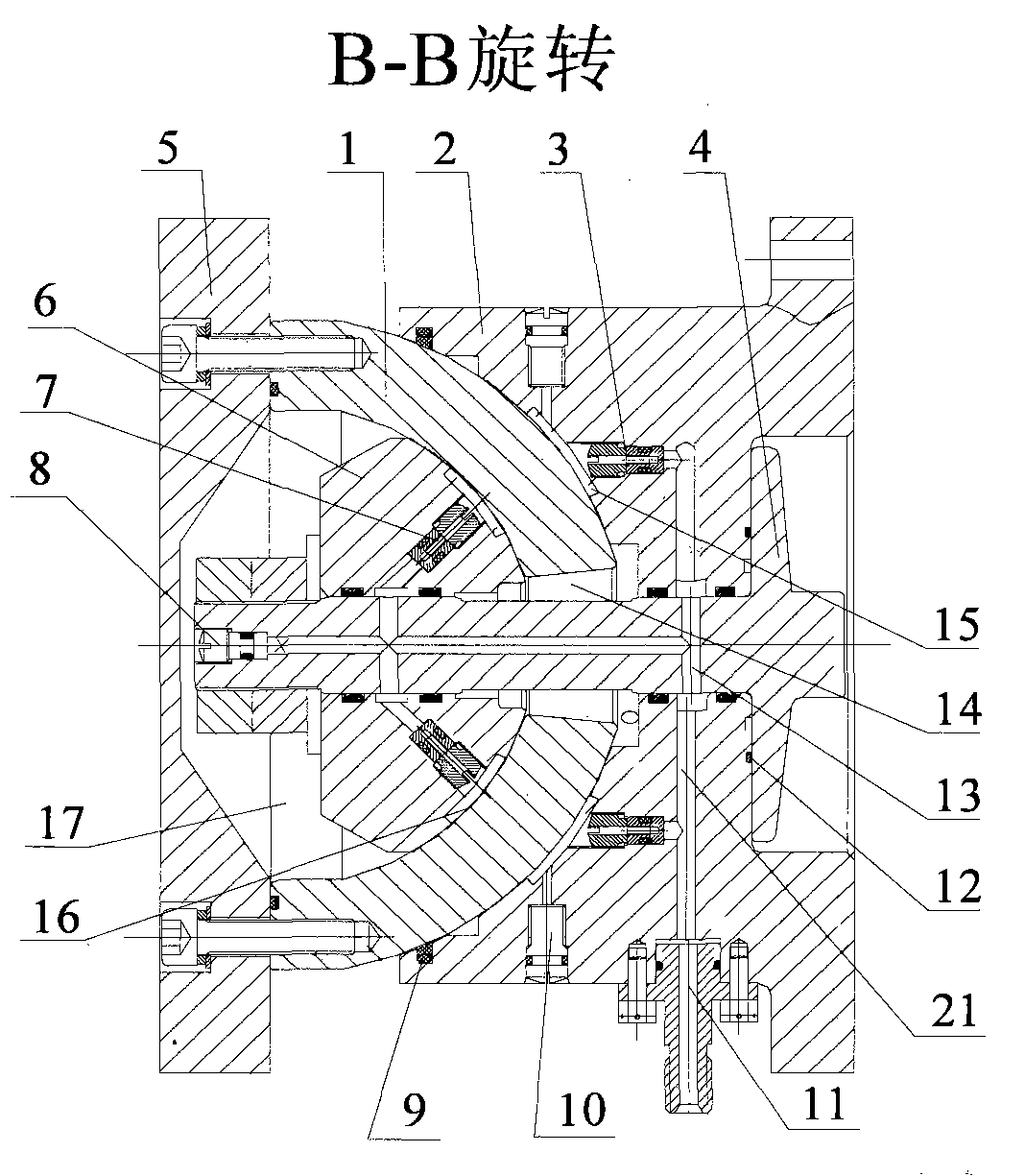

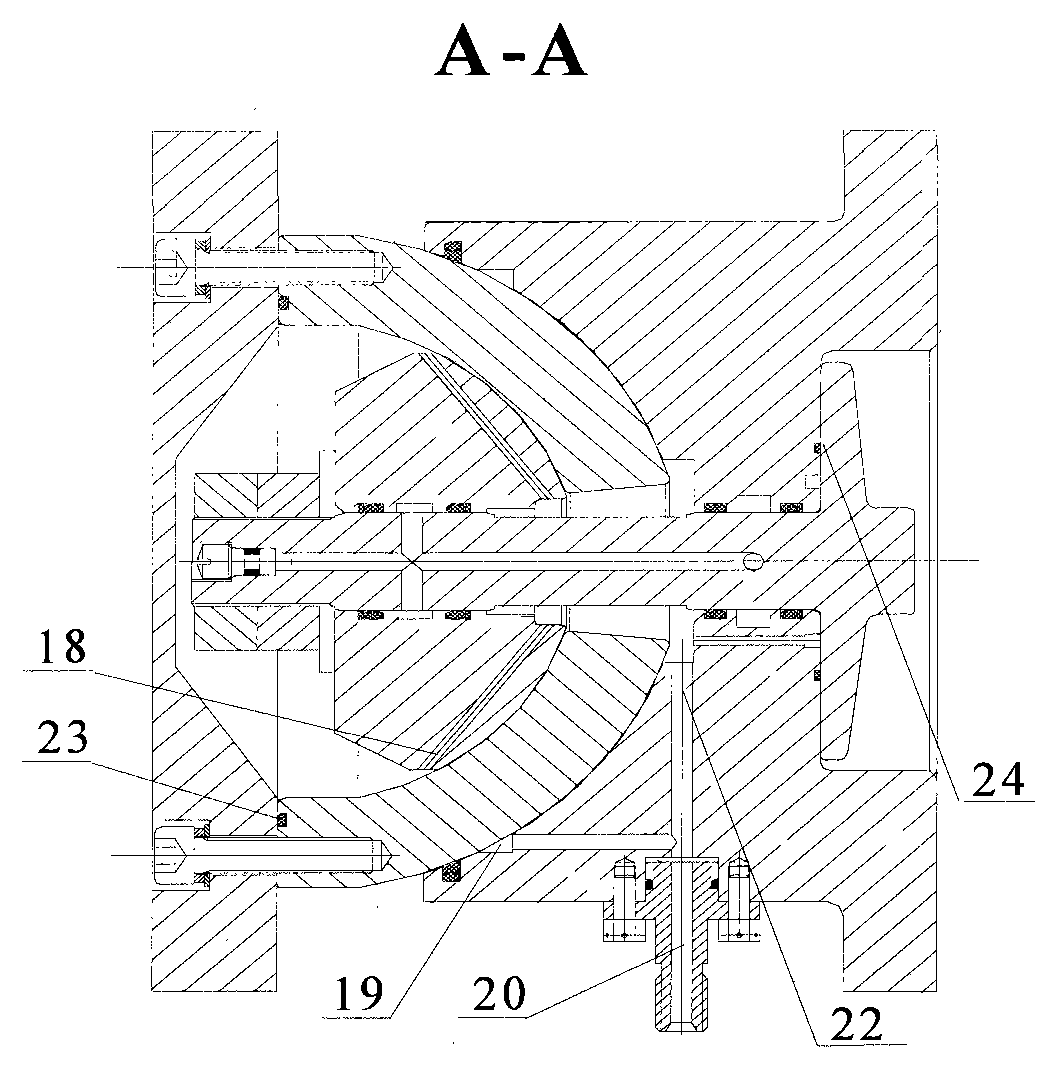

[0025] The three-degree-of-freedom, double-layer oil-film spherical joint of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as Figure 1 to Figure 5 As shown, the three-degree-of-freedom, double-layer oil-film ball joint described in the present invention includes a cylindrical body with a flange, and a ball socket 2 with a concave end surface on one side to form a spherical surface. Different tangential directions of the cross-section are provided with an oil inlet nozzle 11 and an oil return nozzle 20 respectively. A large hemisphere 1 is provided in the concave spherical surface of the ball socket 2, and a small hemisphere 6 is arranged in the large hemisphere 1, and the convex spherical surface of the large hemisphere 1 cooperates with the concave spherical surface of the ball socket 2 to form an inner hydraulic support surface; the large hemisphere The inner concave spherical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com