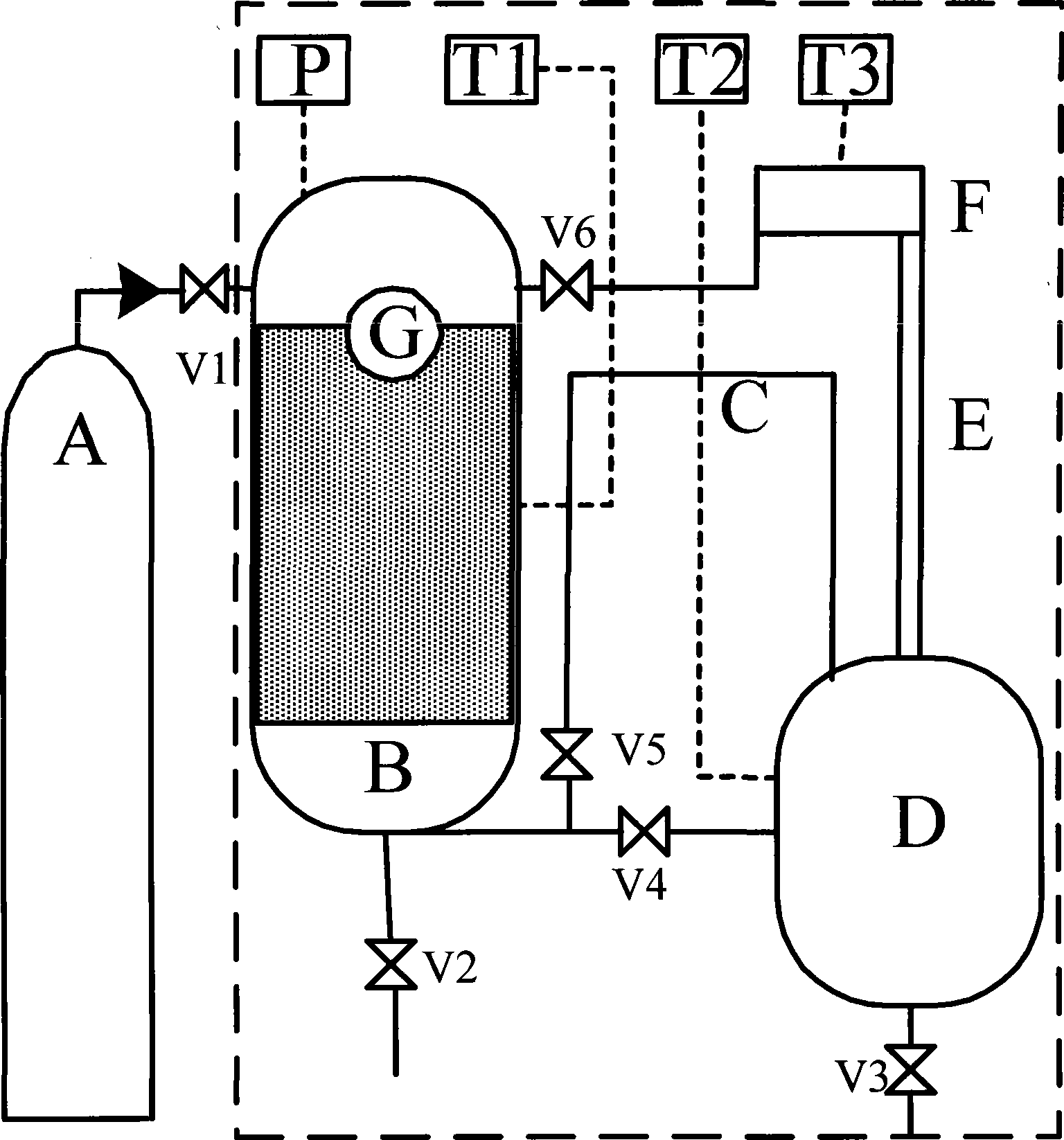

Self-circulation dry cleaning machine

A technology of dry cleaning machines and washing kettles, applied in the field of dry cleaning machines, to achieve the effects of small temperature change range, increased washing effect, and improved mass transfer driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Subcritical Carbon Dioxide Washing of Oily Cotton Fabrics

[0033] Cotton fabric coated with organic oil; carbon dioxide, purity ≥98%. The temperature of the dirt kettle D is 321K. The pressure P is 6MPa, and the temperature T1 is 291K. Dry cleaning self-cycle 3 times (about 27 minutes), the cotton fabric has no oil adhesion, the removal rate is 96%; self-cycle 4 times (about 36 minutes), the oil removal rate is 99%. When the temperature of washing tank B is 297K, dry cleaning self-circulation 2 times (about 18 minutes), the cotton fabric has no oil adhesion, and the removal rate is 94%; self-circulation 3 times, the oil removal rate is 97%.

Embodiment 2

[0035] Subcritical carbon dioxide washing of oily woolen cloth

[0036] Cotton fabric coated with organic oil; carbon dioxide, purity ≥98%. The temperature of the dirt kettle D is 321K, the pressure P is 6MPa, the temperature T1 of the washing kettle B is 297K, the dry cleaning self-circulation is performed twice, the cotton fabric has no oil adhesion, and the removal rate is 89%; the self-circulation is three times, and the oil removal rate is 98%.

Embodiment 3

[0038] Subcritical and supercritical carbon dioxide washing of oily cotton fabrics

[0039] Cotton fabric coated with organic oil; carbon dioxide, purity ≥98%. The temperature of the washing tank B is kept at 313K first, and the pressure P shows about 9MPa, and it is kept for 10 minutes. Then keep the temperature of washing tank B at 297K, and carry out dry cleaning self-circulation twice, and the cotton fabric has no oil adhesion, and the removal rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com