Tamping type coke making coke oven gas collecting device

A collection device and technology of coke oven gas, which is applied in coke ovens, coke oven heating, dry distillation gas discharge devices, etc., can solve the problems of high maintenance costs of smoke and dust removal vehicles, waste of water, electricity and energy, and unsatisfactory performance, and achieve saving Operating cost, improvement of economic benefit, and effect of improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

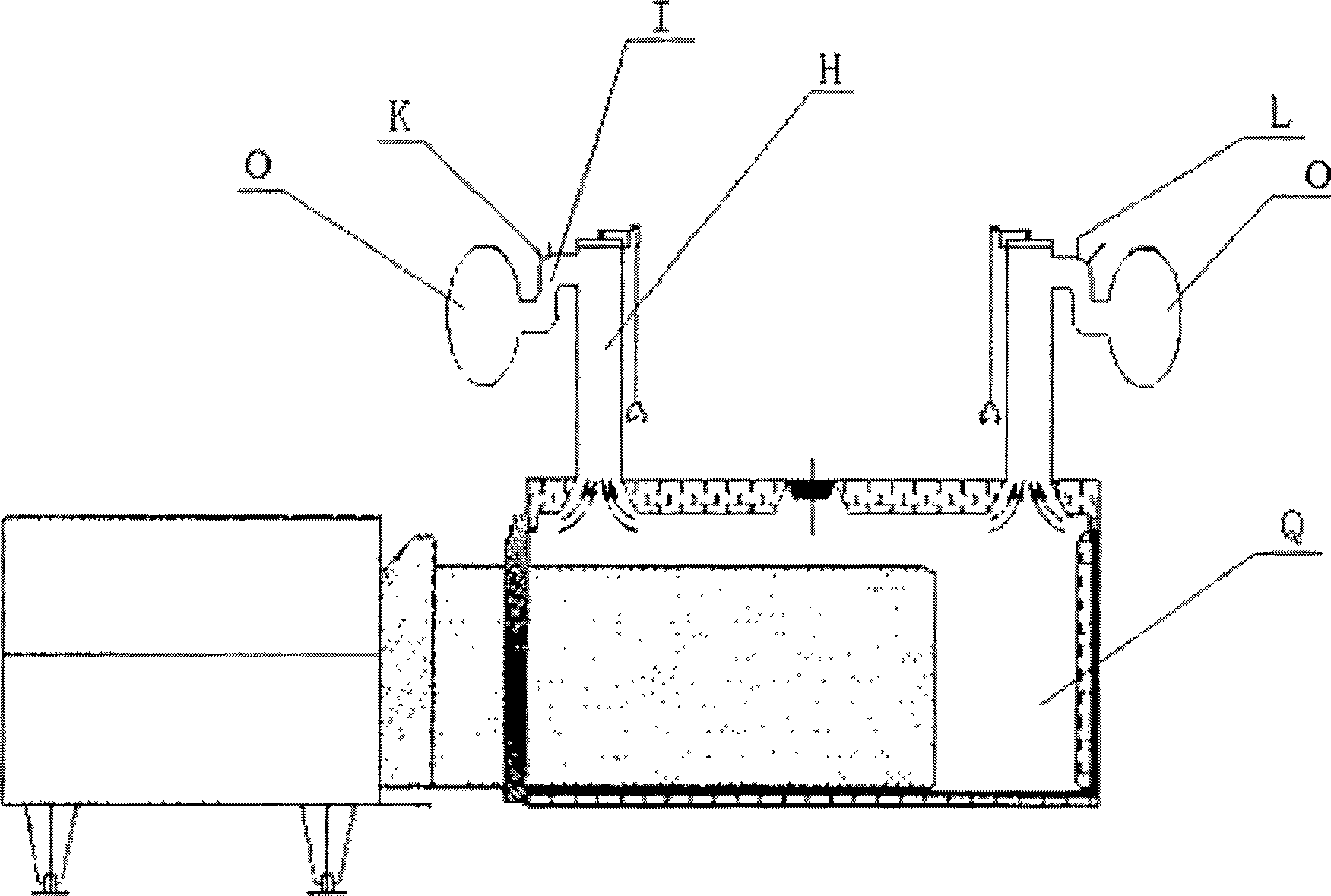

[0026] Such as figure 1 As shown, the tamping type coking coke oven gas collection device is composed of a rising pipe H, a negative pressure smoking device I and a gas collecting pipe O; Gas port; the top nozzle of the riser pipe H is provided with a gas collecting pipe safety device, which is composed of a top cover A, an arm D, a handle B, a support frame G and a pull rod C, and the arm D is connected with the handle B. The end of the warping arm D is movably connected with the top cover A through the connection axis E, the lower end of the handle B is movably connected with the support frame G through the fixed axis F, and the handle end of the handle B is movably connected with the pull rod C through the connection axis E; The negative pressure smoking device I is composed of a spray chamber M, a high-pressure ammonia injection device K and a low-pressure ammonia injection device L. The spray chamber M is an "S"-shaped pipe, the upper nozzle is an air inlet, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com