Tyre belt layer extrusion method production process and equipment

A technology of production process and extrusion process, which is applied in the field of production process and equipment of new radial tire belt layer, can solve the problems of complex production and processing process of spiral structure belt layer, and achieve simplified processing process and high-efficiency production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

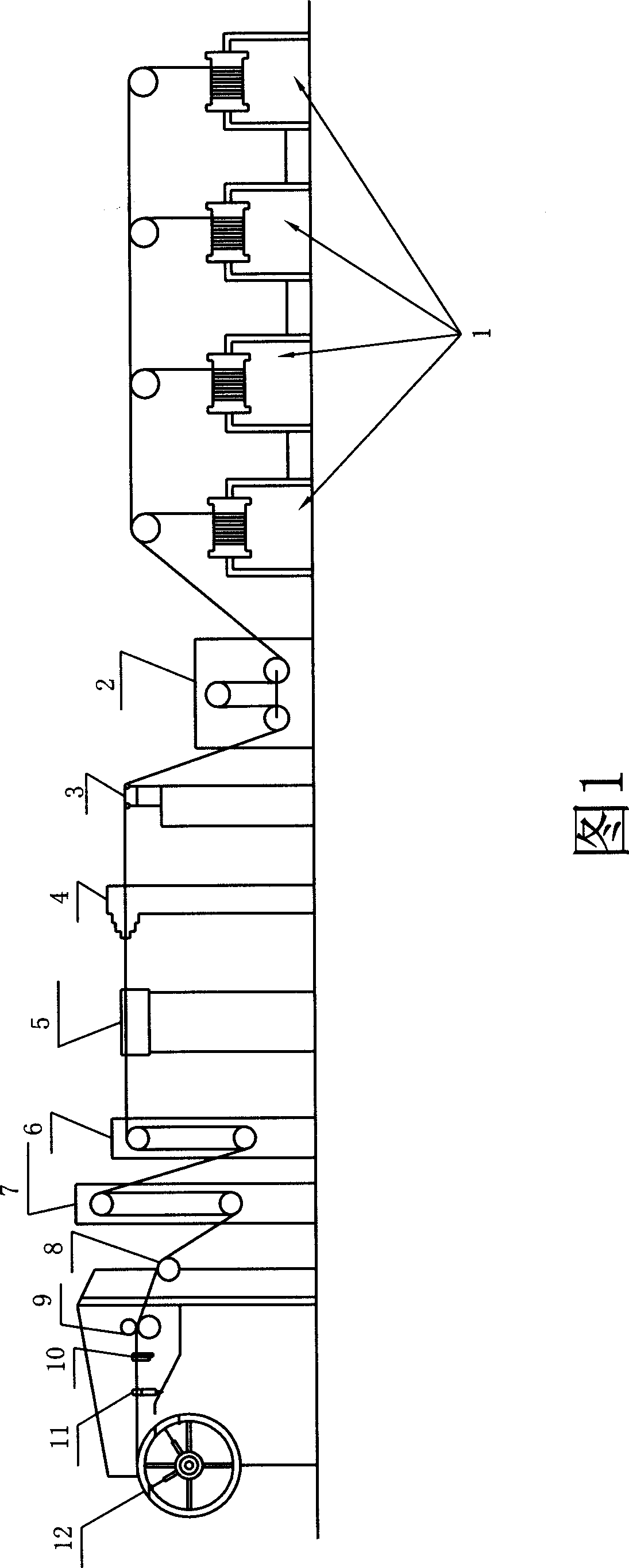

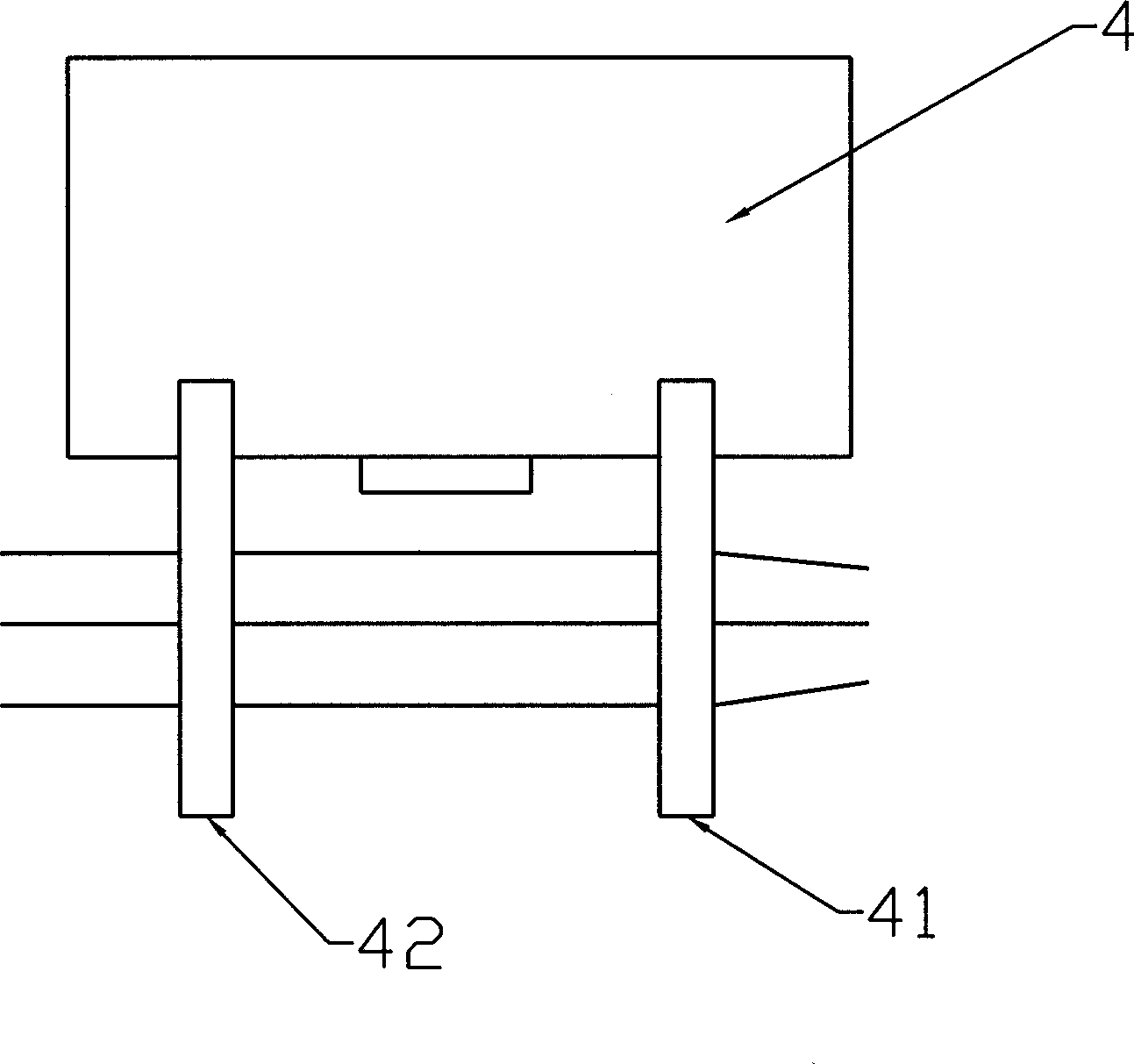

[0028] Embodiment 1: Accompanying drawing 1 is a kind of structure schematic diagram of the extrusion method production equipment of a kind of tire belt layer of the present invention, and it comprises the steel cord frame 1 that arranges in order, preheating device 2, decontamination derusting Dust removal device 3, extrusion device 4, cooling device 5, traction device 6, storage elevating frame 7 and winding device, the winding device is equipped with distance adjustment device 11, cutting device and winding disc 12 in sequence. 3 to 5 steel cords The corresponding steel cord is drawn out from the sub, and the traction by the traction device passes through the preheating device, the decontamination, rust and dust removal device, the extruding device, and the cooling device. An extruder is arranged in the extrusion device, and the extruder is provided with a T-shaped head, and replaceable templates are respectively arranged on both sides of the front and back of the head, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com