Apparatus and method for producing a large-area fibre-composite structural component

A structural component and large-area technology, applied in the direction of household components, high-efficiency propulsion technology, and other household appliances, can solve problems such as the difficulty of placing finished structural components, reduce busy time, prevent the formation of folds or corrugations, and improve laying speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Unless otherwise noted, like reference numbers in the figures refer to identical or functionally identical components.

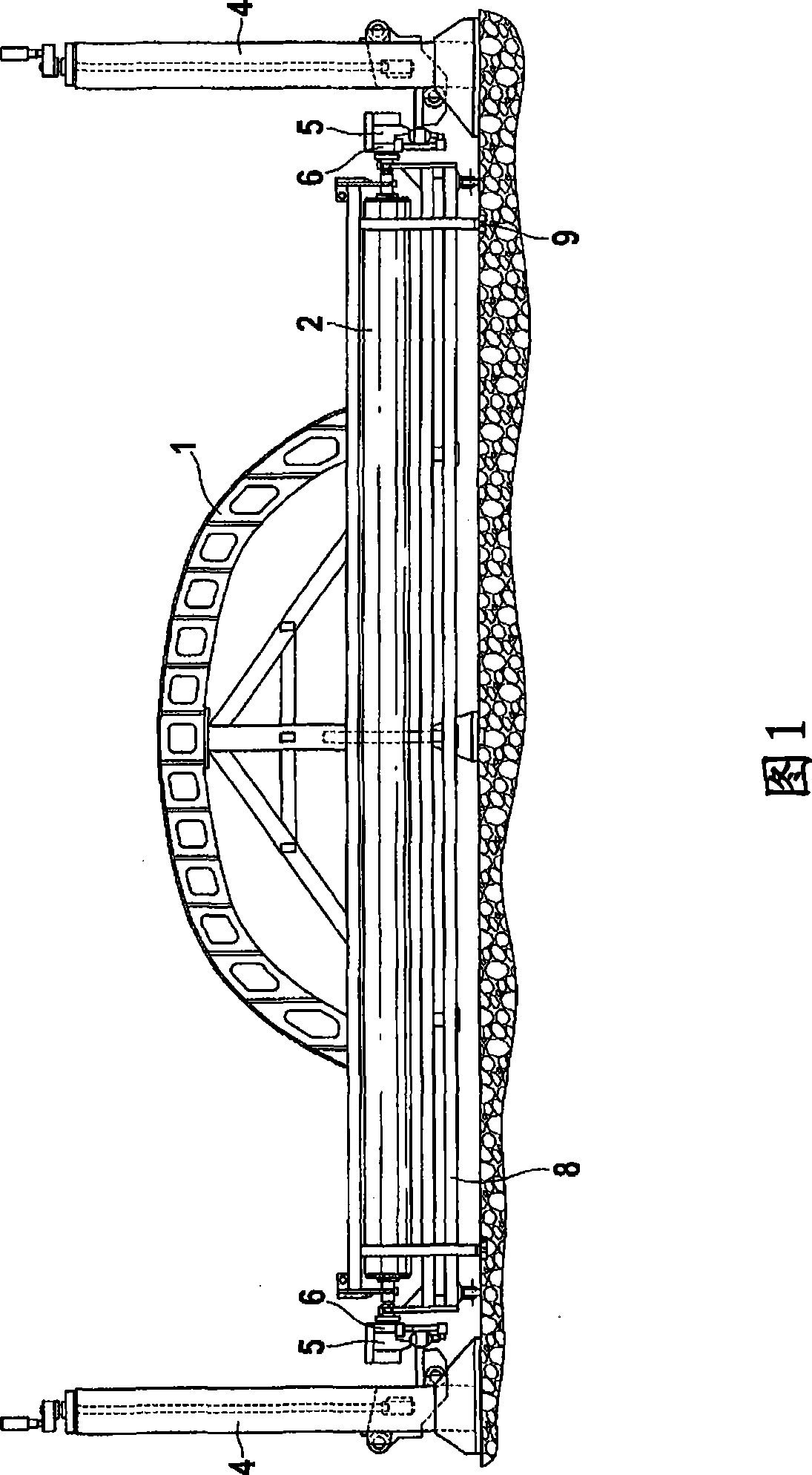

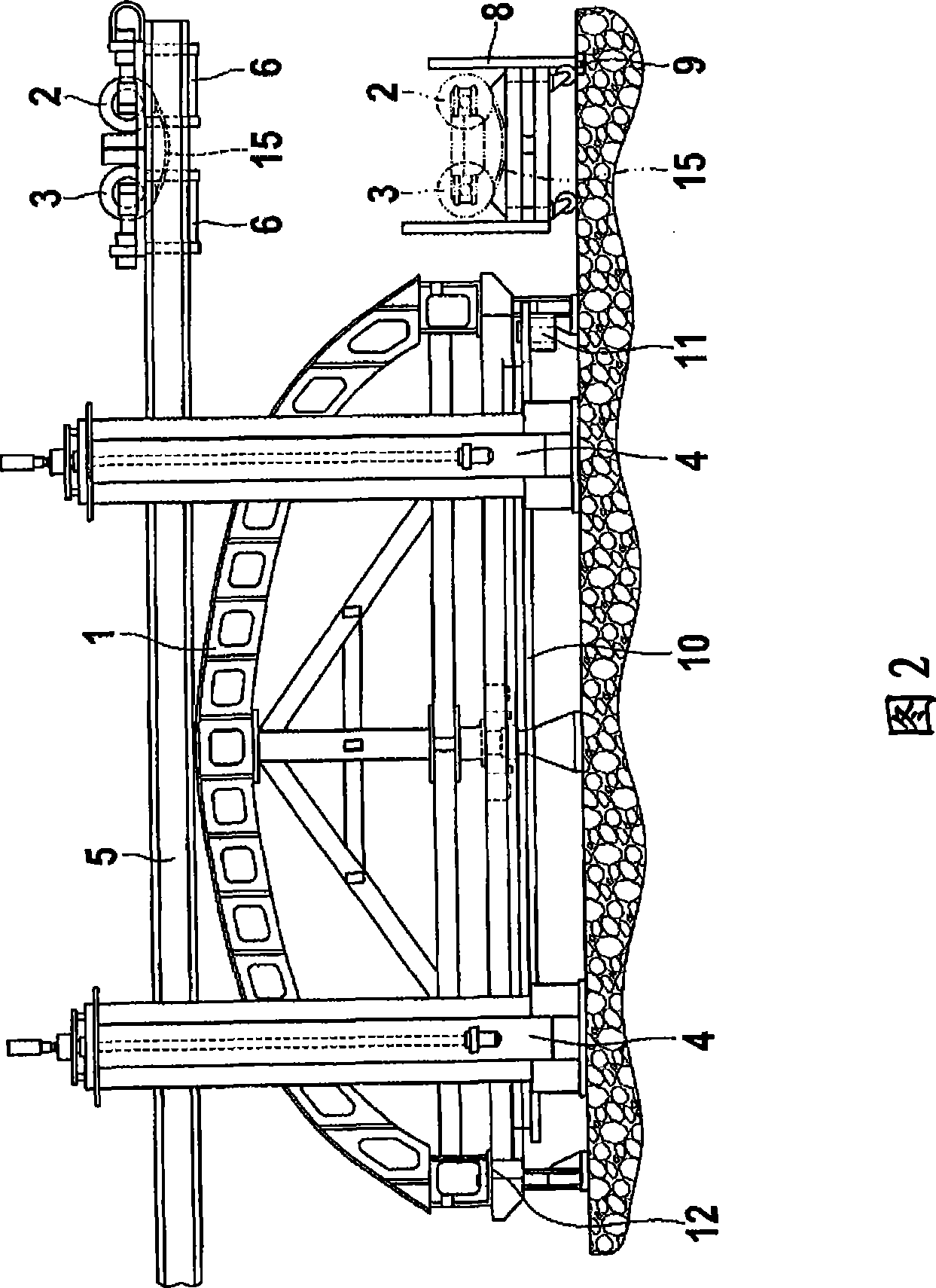

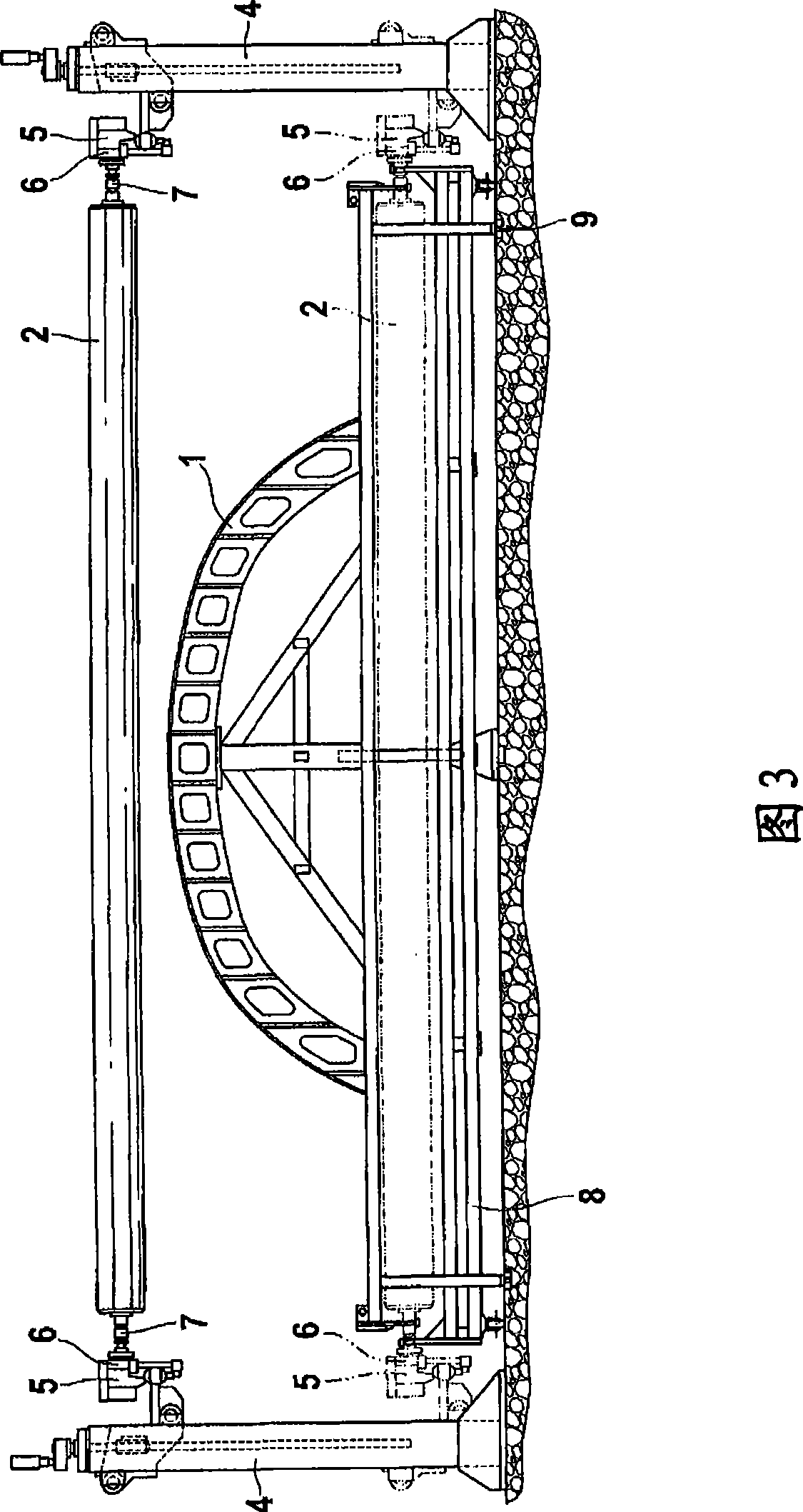

[0035] In FIGS. 1 to 5 , according to a preferred exemplary embodiment of the invention, a device for producing a structural component from a fiber composite material such as carbon fiber reinforced plastic (CRP) is depicted. Among them, Fig. 1 and Fig. 3 are main views, while Fig. 2, Fig. 4 and Fig. 5 are left views of the device in different moving states.

[0036] Preferably, the device given by way of example is provided with a shaped element 1 formed as a positively bonded device, eg of structural steel or the like. The dimension specification of the forming element 1 is adapted to the desired dimension specification of the structural component to be produced, for example a pressure dome. Preferably, in the structural design of the shaped element 1 a suitable compensation has been made for the coefficient of thermal expansion of the molding mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com