Density graduation apparatus with automatic hydraulic sidewall contact device

A pusher and hydraulic technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor simulation, short distance, long operation time, etc., achieve good density simulation performance, eliminate measurement errors, and realize automatic control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

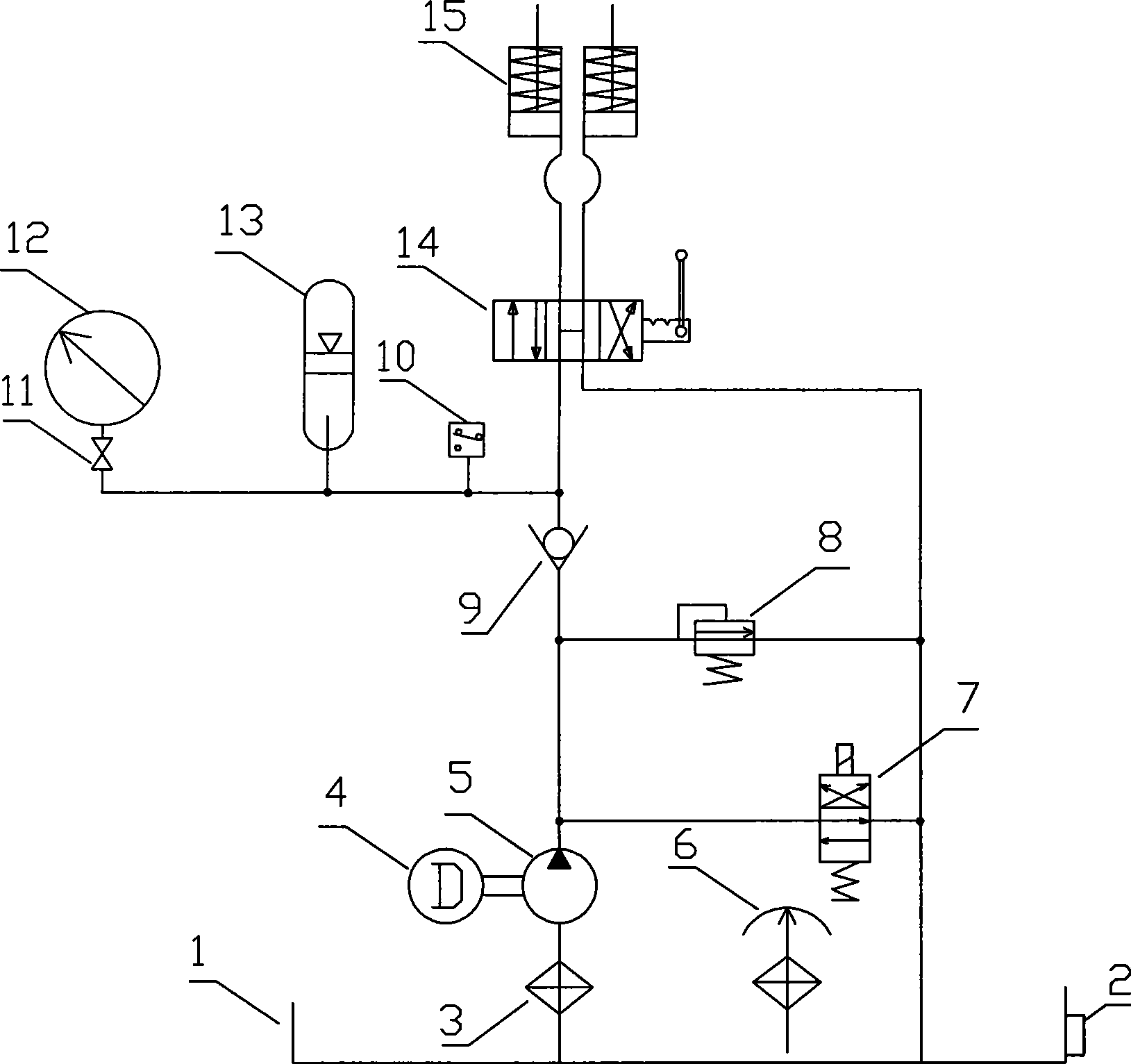

[0026] see figure 1 , the hydraulic pushing device of the present invention comprises a hydraulic cylinder 15, a motor 4, a hydraulic gear pump 5 driven by the motor 4, a fuel tank 1 and an accumulator 13, the fuel tank 1 is connected to the hydraulic gear pump 5, and the hydraulic gear pump 5 and the hydraulic cylinder 15, the accumulator 13 is connected to the hydraulic gear pump 5, the hydraulic pushing device also includes a hydraulic control valve, the hydraulic control valve includes a manual reversing valve 14, a check valve 8 and an electromagnetic reversing valve 7, and a hydraulic cylinder 15 Two hydraulic cylinders 15 are respectively connected to the manual reversing valve 14, and are respectively connected to the hydraulic gear pump 5 through their respective pipelines. The manual reversing valve 14 can be operated to alternately select one of the hydraulic cylinders 15 to work. A check valve 8 and an electromagnetic reversing valve 7 are respectively connected be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com