Heat-storing material

A heat storage material and heat storage technology, applied in building insulation materials, climate change adaptation, building components, etc., can solve the problems of large land occupation, short service life, poor heat preservation effect, etc., to save land, reduce weight, The effect of reducing the factors of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

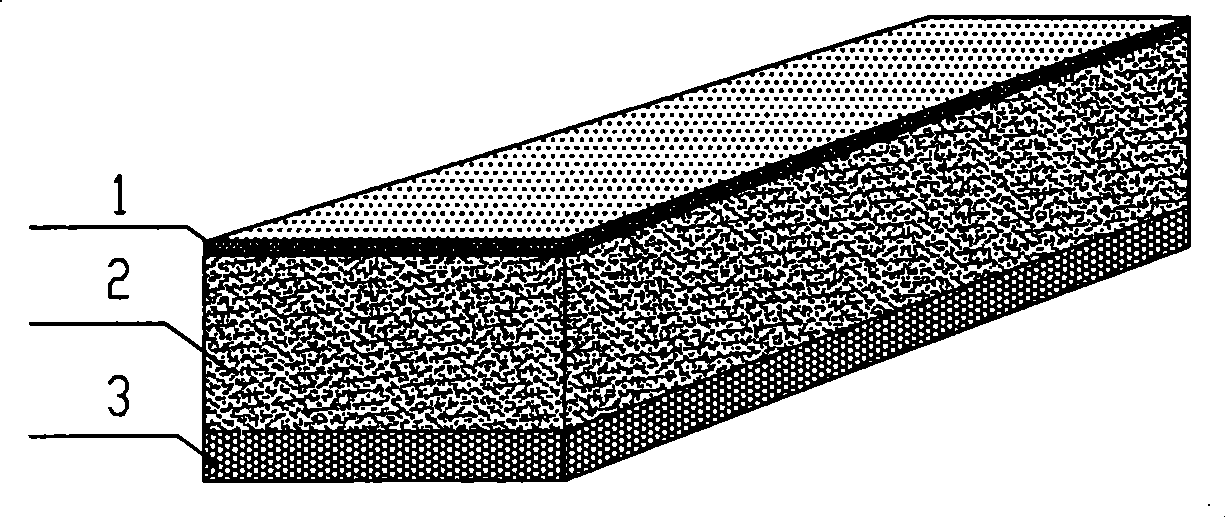

[0025] A heat storage material, which is composed of an outer heat insulation layer, a middle heat storage layer, and an inner surface breathable and water permeable layer. The outer heat insulation layer is a heat insulation material; the middle heat storage layer is made of It is composed of materials with functions of air permeability, water permeability, toughness, rigidity, water storage and heat storage; the inner surface air-permeable and water-permeable layer is composed of materials with good air permeability and water permeability.

Embodiment 2

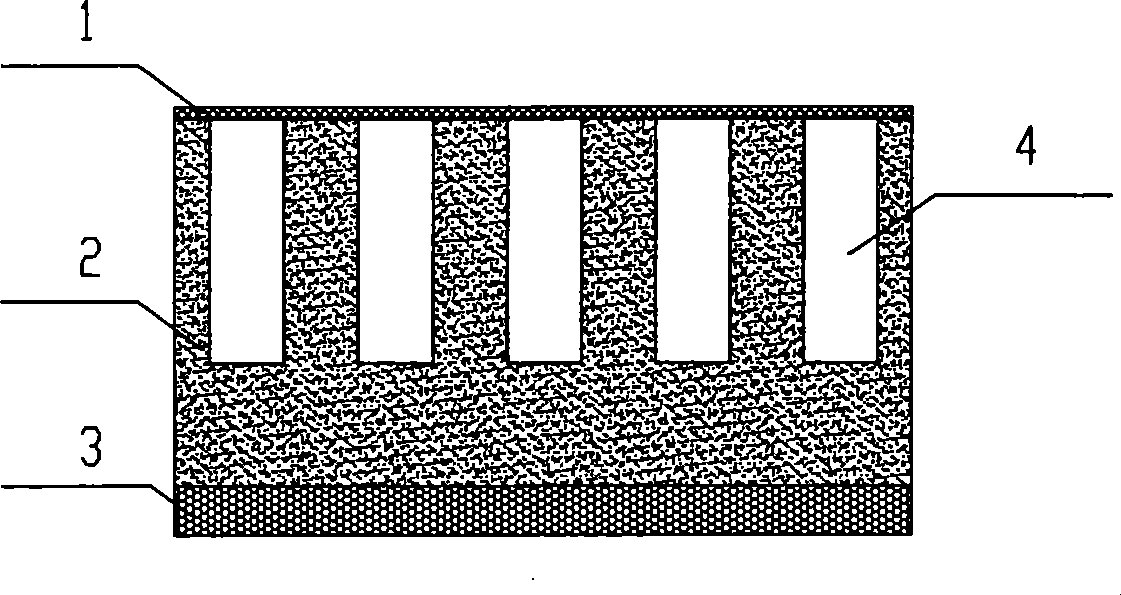

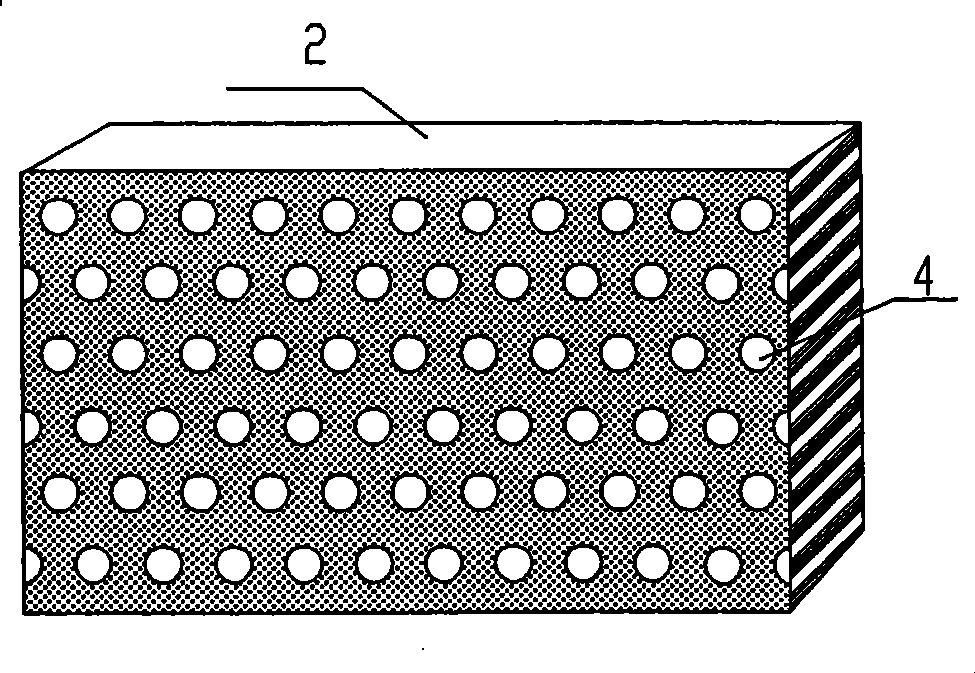

[0027] A plant straw heat storage material, see ( Figure 1~2 ), it is composed of outer heat insulation layer, middle heat storage layer and inner surface air permeable layer, described outer heat insulation layer 1 is 15mm in thickness; described middle heat storage layer 2 is made of plant straw After pulverization, it is fully fermented to decompose the sugar contained in it, and after forming the base material, the mixture formed by mixing the base material and the binder is pressed into a heat storage wall with a stable density of 100mm and a thickness of 100mm, and is pressed on the surface. A number of cylindrical heat storage holes 4 with a diameter of 10mm are distributed in a honeycomb shape, and the depth is less than the thickness of the wall block, see ( image 3 ); the air permeable and water permeable layer of the inner surface is a sponge with a thickness of 1 mm.

Embodiment 3

[0029] A plant straw heat storage material, the thickness of the outer heat insulation layer 1 is 20mm; the thickness of the middle heat storage layer 2 is 150mm, and the diameter of the cylindrical heat storage hole 4 is 30mm; The thickness of the breathable and water-permeable layer 3 is 10 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com