Toilet without cistern

A technology for toilets without water tanks, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., and can solve problems such as poor flushing effect, complex structure, and large water consumption of toilets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

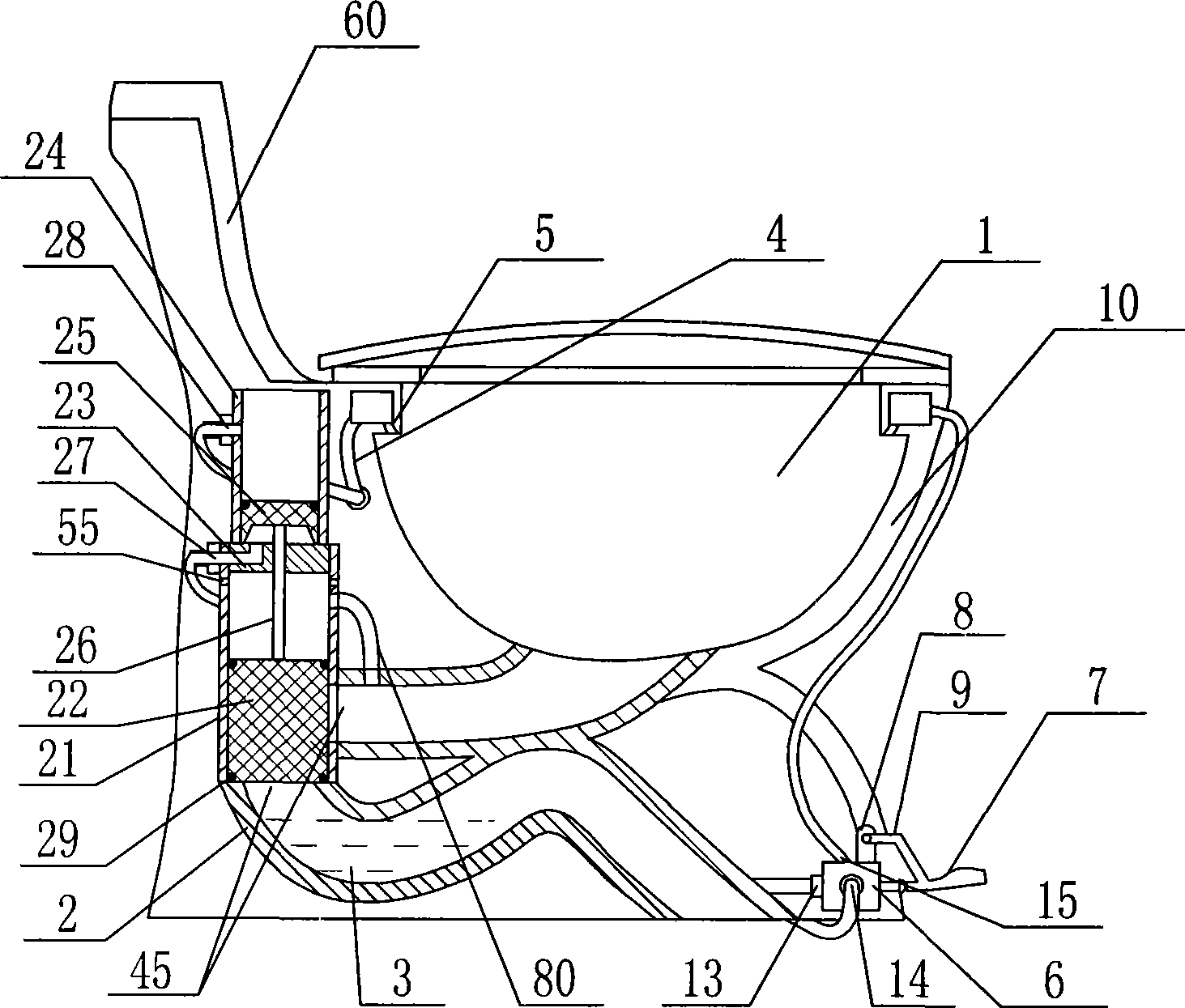

[0021] Embodiment one: refer to figure 1 and Figure 4 , the negative pressure generating driving device is arranged at the opening 45 of the sewage pipe 2 above the water trap 3, the negative pressure generating driving device includes a pumping cylinder 21, the side and bottom of the pumping cylinder 21 communicate with the opening 45 of the sewage pipe 2, and the pumping The cylinder 21 is provided with a gravity column 22 that can communicate with and block the sewage pipe 2, and the upper side wall of the pumping cylinder 21 is provided with a return pipe 80 and a number of exhaust holes 55 that communicate with the sewage pipe 2. The accumulated water in the pumping cylinder 21 above 22 is discharged into the sewage pipe 2, the lower end of the gravity column 22 is provided with a sealing ring 29 that seals the water trap 3, and the top of the pumping cylinder 21 is provided with a hydraulic cylinder 24. The cylinder 24 includes a bottom flange 23 and an internal piston...

Embodiment 2

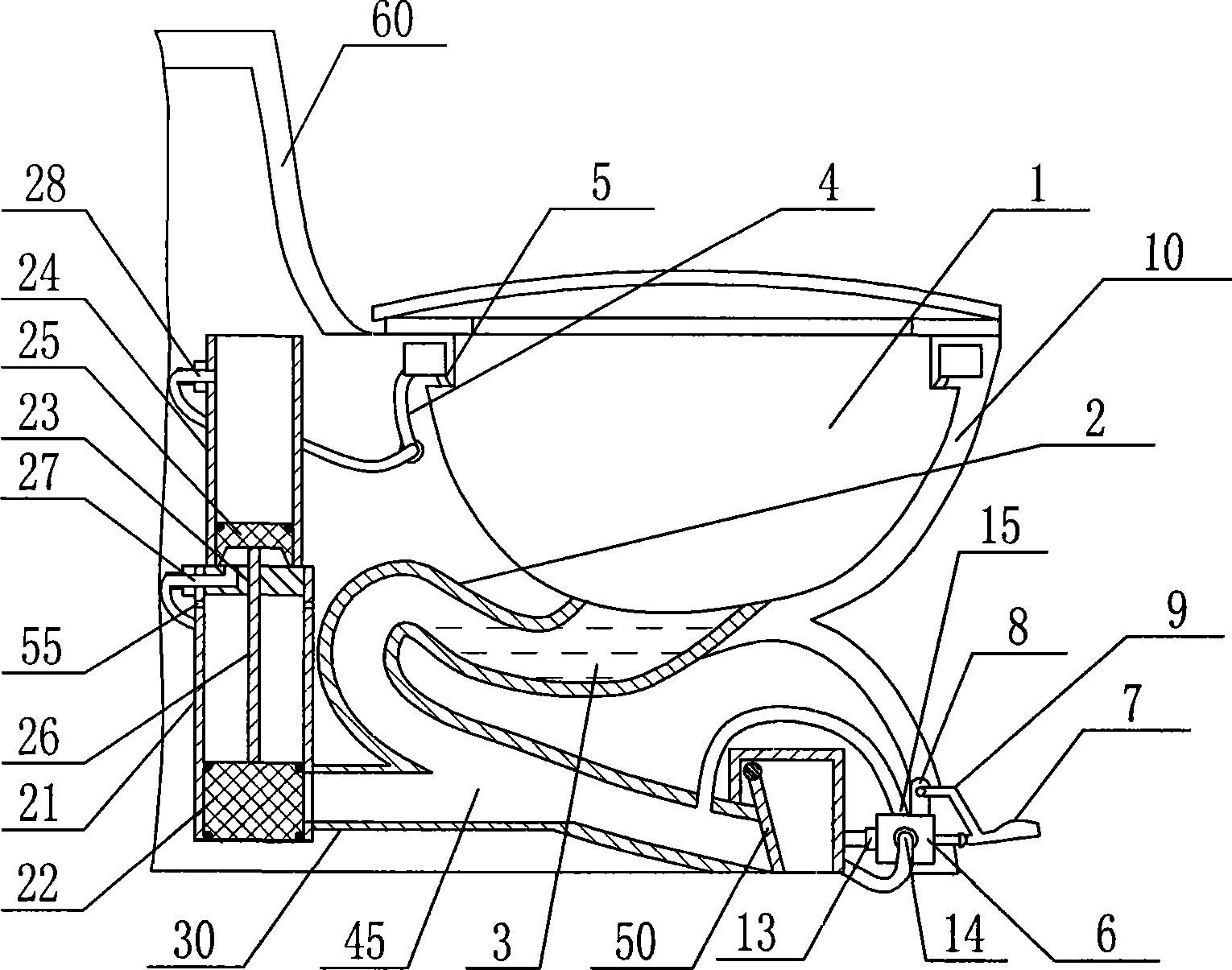

[0024] Embodiment two: refer to figure 2, and the difference from Embodiment 1 is that the gravity column 22 of the negative pressure generation drive device draws negative pressure on the closed space in the sewage pipe 2 at the bottom of the trap 3 through the pipeline 30, and a single unit is provided at the lower port of the sewage pipe 2. to valve 50. This embodiment is applicable to the toilet with the water trap 3 arranged on the upper part of the sewage pipe 2, and the lower port of the sewage pipe 2 must be provided with a one-way valve 50, otherwise the negative pressure cannot be drawn, and the water return port 15 on the water valve 6 passes through the pipeline. Connect to the top of the lower outlet of the sewage pipe 2, and flush the seal of the one-way valve 50.

Embodiment 3

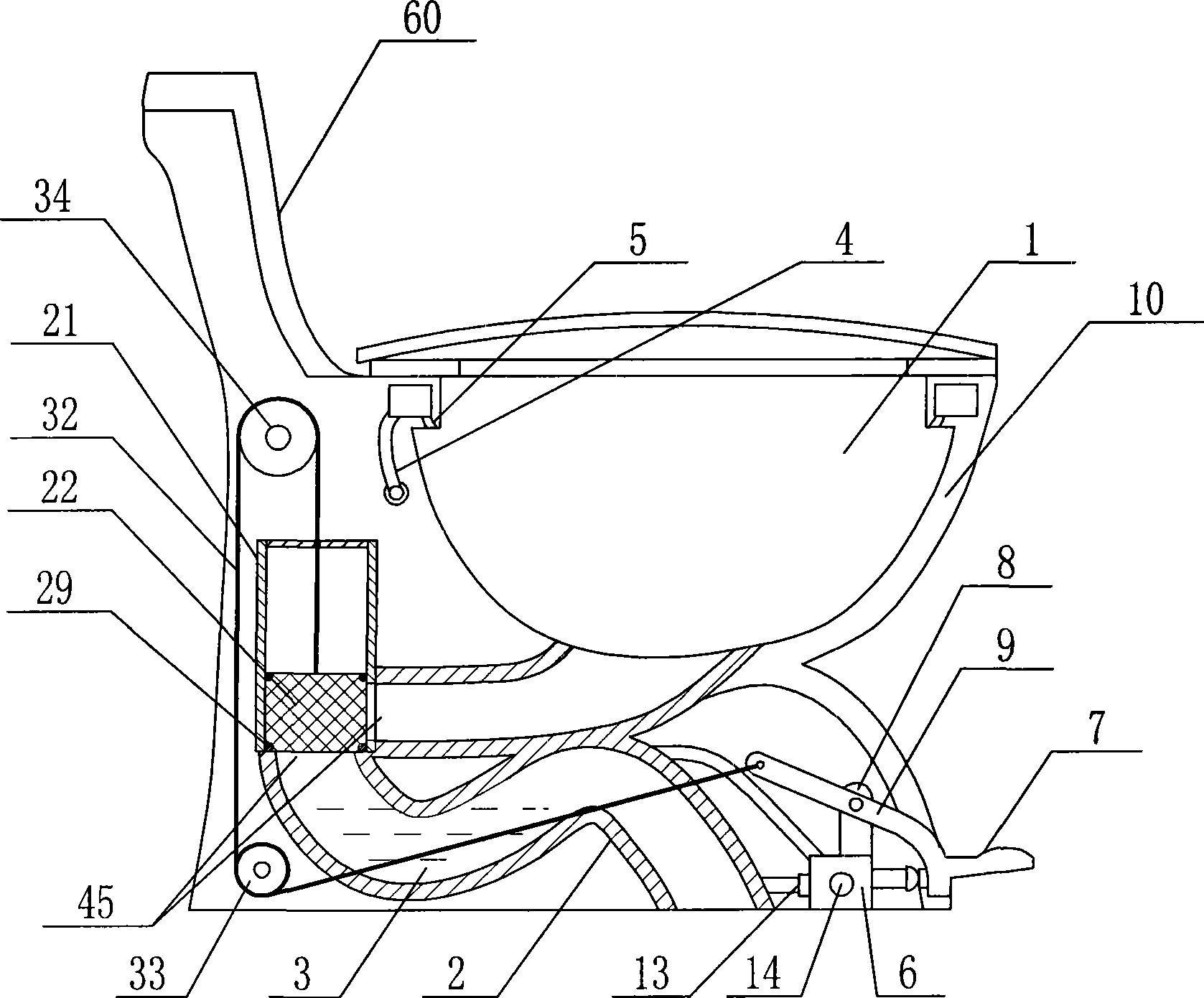

[0025] Embodiment three: refer to image 3 , is different from Embodiment 1: the rear end of the pedal 7 is provided with a lever 9 hinged by a bracket 8, and the lever 9 is connected to the top of the gravity column 22 through the fixed pulley 33 and the fixed pulley 34 through the wire rope 32, and the negative pressure generates the drive The negative pressure power of the device comes from the lever force. By stepping on the pedal 7, the lever 9 is driven, and the lever 9 drives the gravity column 22 to rise to perform negative pressure on the space above the water trap 3. At the same time, the water delivery port 14 of the water valve 6 and the The water delivery pipe 4 is directly connected, and the bedpan 1 is flushed through the water flushing pipe 5 . This embodiment does not need to use components such as the hydraulic cylinder and the piston described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com