Wire-cutting device for sewing machine

A technology of cutting device and sewing machine, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing machine loop mechanism, etc., and can solve the problem of catching upper thread and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

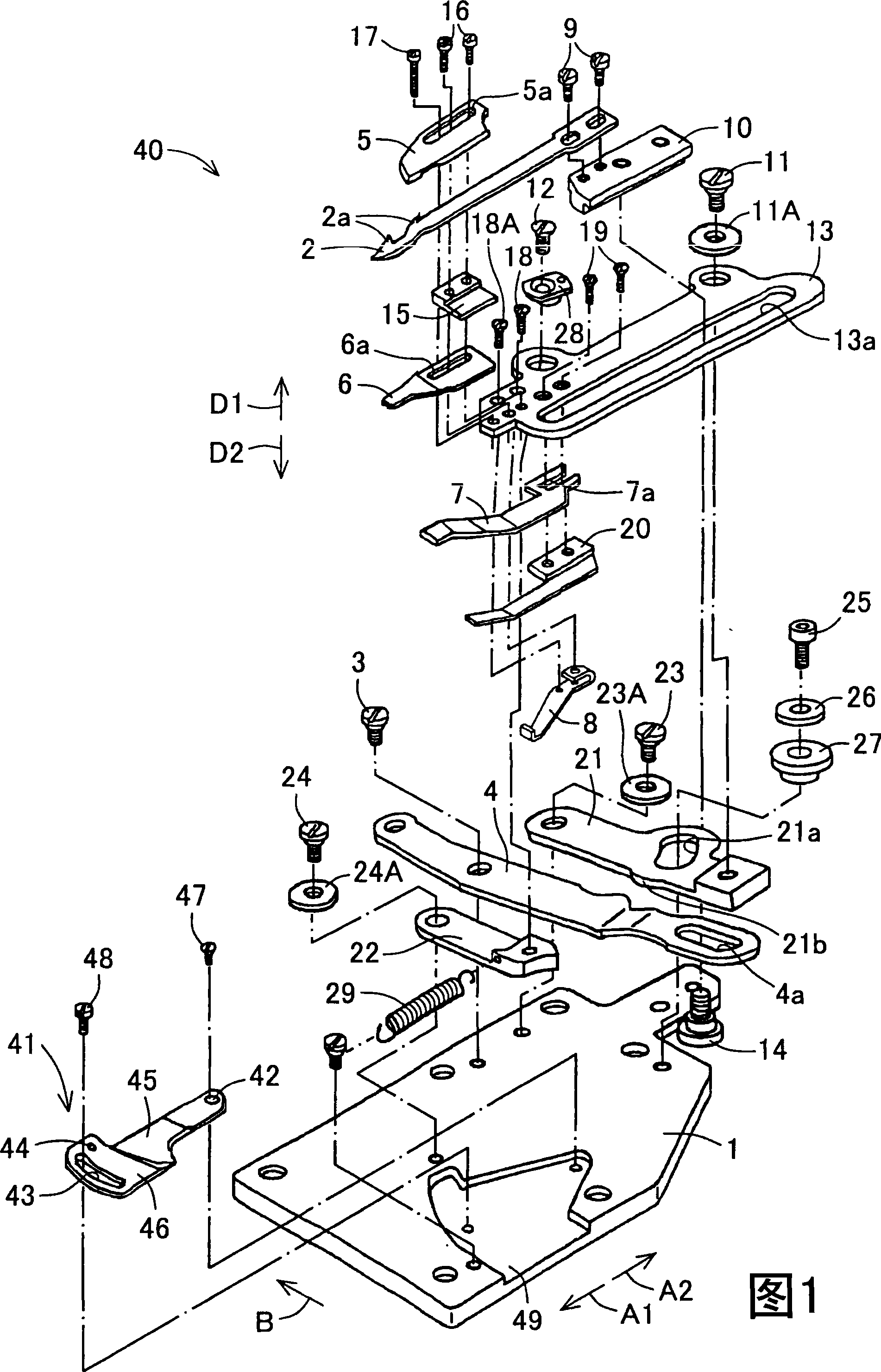

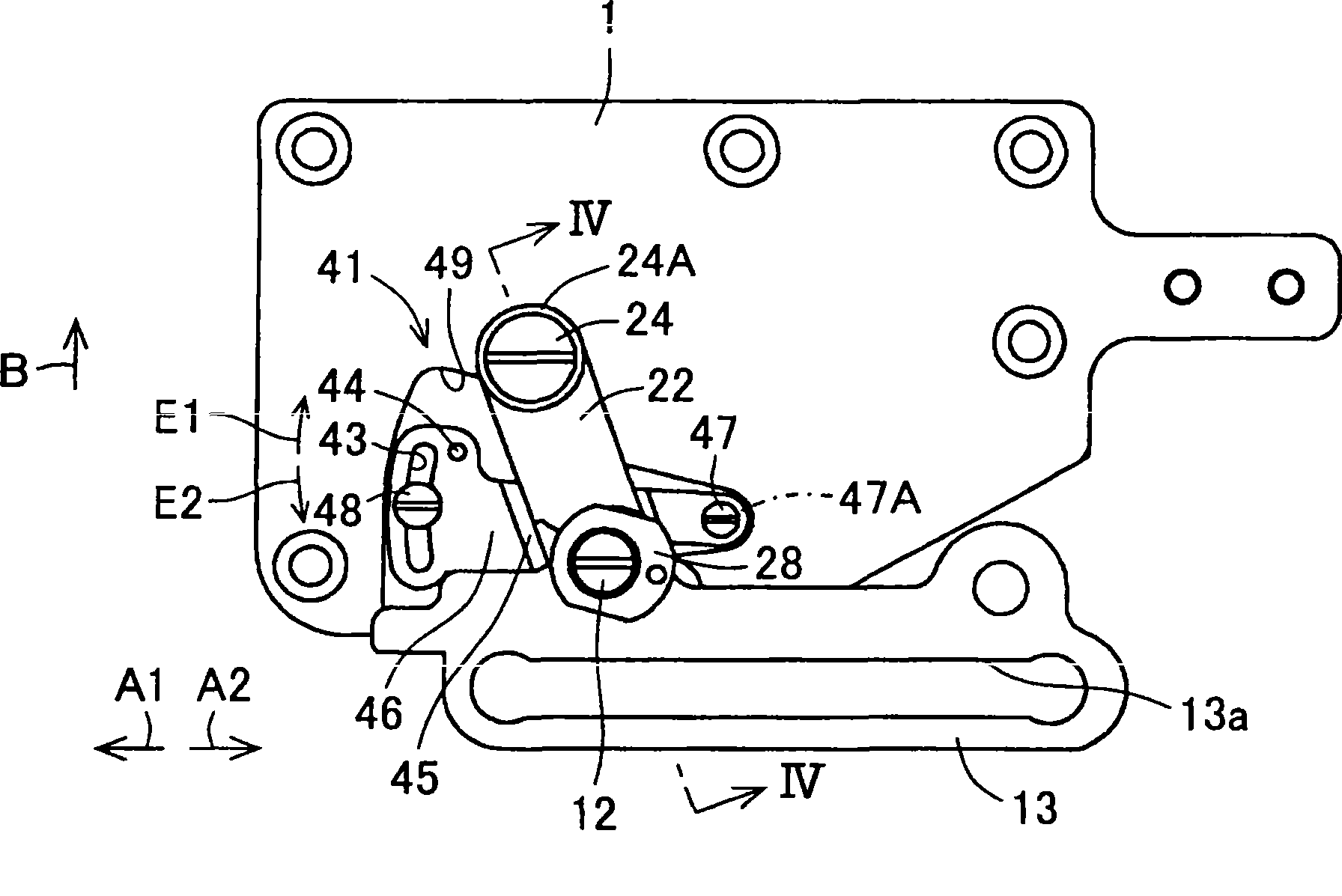

[0024] Fig. 1 is an exploded perspective view of a yarn cutting device 40 of a sewing machine according to an embodiment of the present invention, figure 2 It is a plan view of the yarn cutting device 40 with some components omitted. In the base of the double circular stitch sewing machine or the flat stitch sewing machine, viewed from the side of the sewing operator, there is arranged below the needle jack plate (not shown in the figure) with the needle drop portion 31, which is depicted as a circular movement track in plan view. 32 (refer to the Figure 10 ) the looper 33 that swings along the forward direction A1 and the backward direction A2, on the downstream side ( figure 2 Above), the yarn cutting device 40 of this embodiment is installed.

[0025] The above-mentioned yarn cutting device 40 includes a movable blade 2 , a driving rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com